Group string connection structure possessing transparent electrode crystalline silicon photovoltaic cell

A photovoltaic cell and transparent electrode technology, which is applied in the field of solar cells, can solve the problems of small space and achieve the effects of reducing usage, increasing the area that can generate electricity, and convenient combination and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

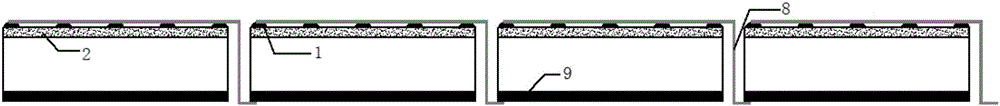

[0061] (1) Classify monocrystalline silicon cells according to grades. The cells are of M2 specification. The front and back electrodes of the cells are transparent conductive film-metal composite electrodes. The number of grid lines is 40, the line width is 30um, and the line length is 2mm.

[0062] (2) Make thin copper wires on the transparent conductive film-metal composite electrodes of the battery sheet. The diameter of the copper wires is 50um, and the number is 30. The thin copper wires intersect vertically with the metal thin grid wires of the composite electrodes, and are welded in series In the process, laser welding is used to vertically bond together, and at the same time, the front and back of adjacent cells are connected in series. Every 10 battery slices are connected in series through thin copper wires to form a battery string, and every 6 battery strings are connected in series through welding ribbons.

[0063] (3) Laminate in the order of photovoltaic glass,...

Embodiment 2

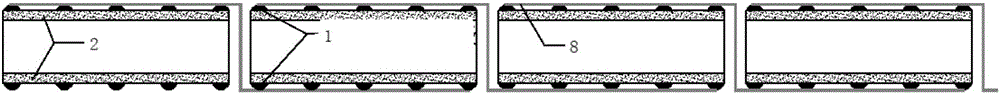

[0069] (1) Classify the monocrystalline silicon cells according to grades. The cell is of M2 specification. The front electrode of the cell is a transparent conductive film-metal composite electrode, and the back electrode is a metal electrode. On the transparent conductive film is a group of parallel equidistant metal fine grid lines, the number is 30, the line width is 50um, and the line length is 50mm.

[0070] (2) Cut the M2 cell into two halves;

[0071] (3) The half-cell strings are laminated in the order of TPA, EVA, polymer containing copper wire, battery string, polymer containing copper mesh, EVA, and photovoltaic glass. The diameter of the copper wire is 100um, and the number is 15.

[0072] (4) Use a laminator for lamination at 150°C to cross-link the EVA and package the battery strings, photovoltaic glass and TPA into a whole. The low-melting-point metal attached to the copper wire is combined with the metal fine grid on the conductive film, and at the same time...

Embodiment 3

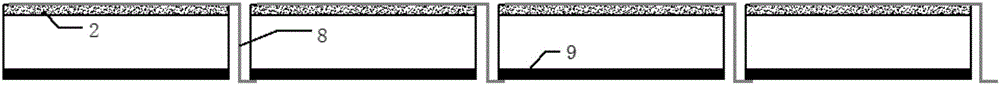

[0077] (1) Classify the monocrystalline silicon cells according to grades. The cell is of M2 specification. The front electrode of the cell is a transparent conductive film-metal composite electrode, and the back electrode is a metal electrode. Metal electrodes with a circular pattern on the transparent conductive film have a diameter of 100um, and the distance between the geometric centers of adjacent patterns is 2mm.

[0078] (2) The cell strings are stacked in the order of TPA, EVA, polymer containing copper wires, battery strings, polymer containing copper mesh, EVA, and photovoltaic glass. The diameter of the copper wire is 100um, and the number is 15.

[0079] (3) Use a laminator to carry out lamination treatment at 150°C to cross-link the EVA and package the battery string, photovoltaic glass and TPA into a whole. The low-melting-point metal attached to the copper wire is combined with the metal electrodes on the conductive film, and at the same time connects the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com