A connection structure for crystalline silicon photovoltaic cells with transparent electrodes

A photovoltaic cell and connection structure technology, applied in the field of solar cells, can solve the problems of reduced reliability of components, unfavorable cell efficiency, and increased cost, and achieve the effects of improving power output, reducing production costs, and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

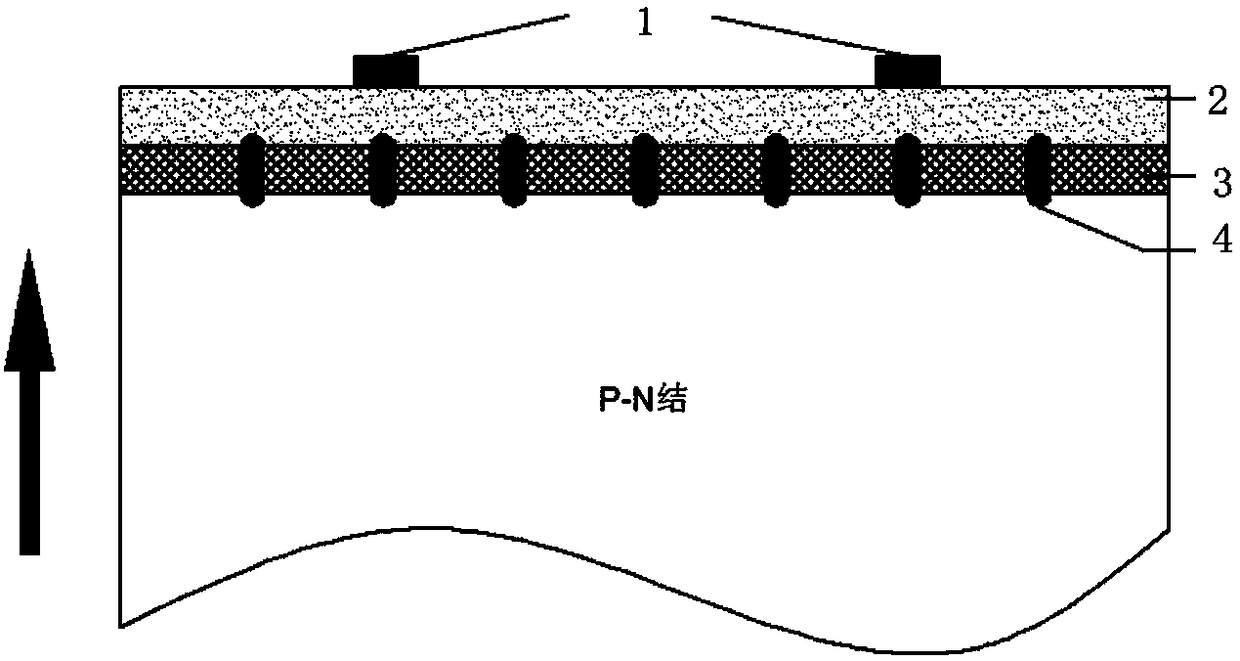

[0051] (1) Efficiency classification of monocrystalline cells is carried out. The cells are of M2 specification, and the front and back electrodes are both transparent conductive film-metal composite electrodes.

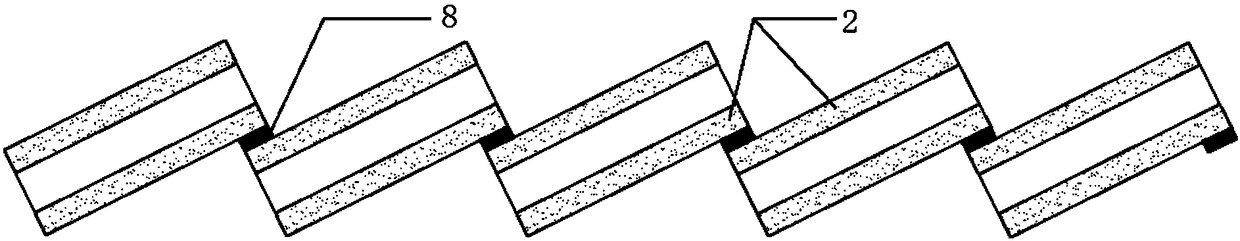

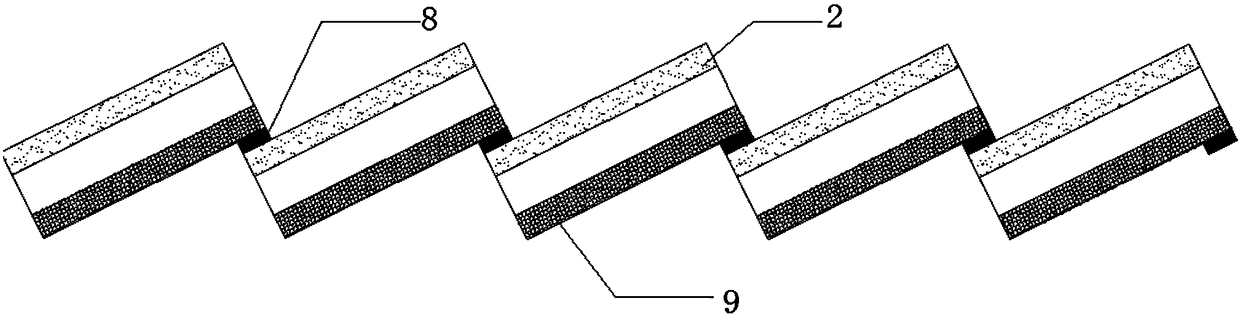

[0052] (2) Apply solder paste to the overlapping parts of the battery sheets, and make lead wires connecting each battery string and junction box. The overlapping width of the front and back of the battery slices is 1.5mm. Every 10 battery slices are stacked in series to form a battery string, and every 6 battery strings are connected in series through welding ribbons.

[0053] (3) Laminate in the order of photovoltaic glass, EVA, battery string, EVA, and photovoltaic glass from bottom to top.

[0054] (4) Use a laminator for lamination at 140°C to cross-link the EVA and combine the battery string with the photovoltaic glass package.

[0055] (5) Perform trimming and EL testing.

[0056] (6) After the package is framed and glued, it is cured for 24 to 48 hours, and...

Embodiment 2

[0059] (1) Classify the efficiency of monocrystalline cells. The cell is of M2 specification. The front electrode is a transparent conductive film-metal composite electrode, and the back electrode is a metal electrode.

[0060] (2) Cut the M2 cell into two halves;

[0061] (3) Use conductive tape to overlap the front and back of adjacent half-cells, and make lead wires connecting each battery string and junction box. The overlapping width of the front and back of the half-cells is 2mm. Every 20 half-cells are stacked in series to form a battery string, and every 6 battery strings are connected in series through welding ribbons.

[0062] (4) Laminate in the order of TPA, EVA, battery string, EVA, and photovoltaic glass from bottom to top.

[0063] (5) Use an autoclave for lamination at 150°C to cross-link the EVA and combine the battery strings, photovoltaic glass and TPA packaging together.

[0064] (6) Perform trimming and EL testing.

[0065] (7) After the package is fram...

Embodiment 3

[0068] (1) The efficiency of the polycrystalline cells is graded. The cell is of M2 specification. The front electrode is a transparent conductive film-metal composite electrode, and the back electrode is a metal electrode.

[0069] (2) Use conductive glue to overlap the front and back of adjacent battery sheets, and make lead wires connecting each battery string and junction box. The overlapping width of the front and back of the battery slices is 1mm. Every 10 battery slices are stacked in series to form a battery string, and every 6 battery strings are connected in series through welding ribbons.

[0070] (3) Laminate in the order of TPA, EVA, battery string, EVA, and photovoltaic glass from bottom to top.

[0071] (4) Use a laminator for lamination at 140°C to cross-link the EVA and combine the battery strings, photovoltaic glass and TPA packaging together.

[0072] (5) Perform trimming and EL testing.

[0073] (6) After the package is framed and glued, it is cured for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com