Distributed optical fiber monitoring system and monitoring method for seepage velocity in hydraulic structures

A technology of distributed optical fiber and monitoring system, which is applied in the direction of fluid velocity measurement, velocity/acceleration/shock measurement, and measuring devices, etc., which can solve the problems of incomplete reflection of leakage information, missed detection, and difficulty in functioning, etc., to increase contrast reliability and reliability, and the effect of ensuring the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

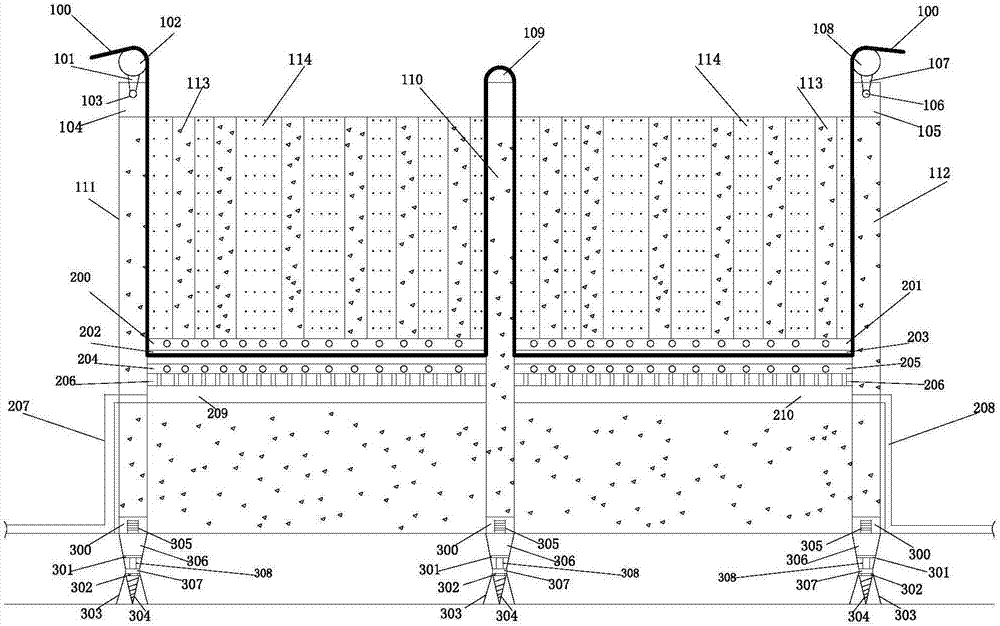

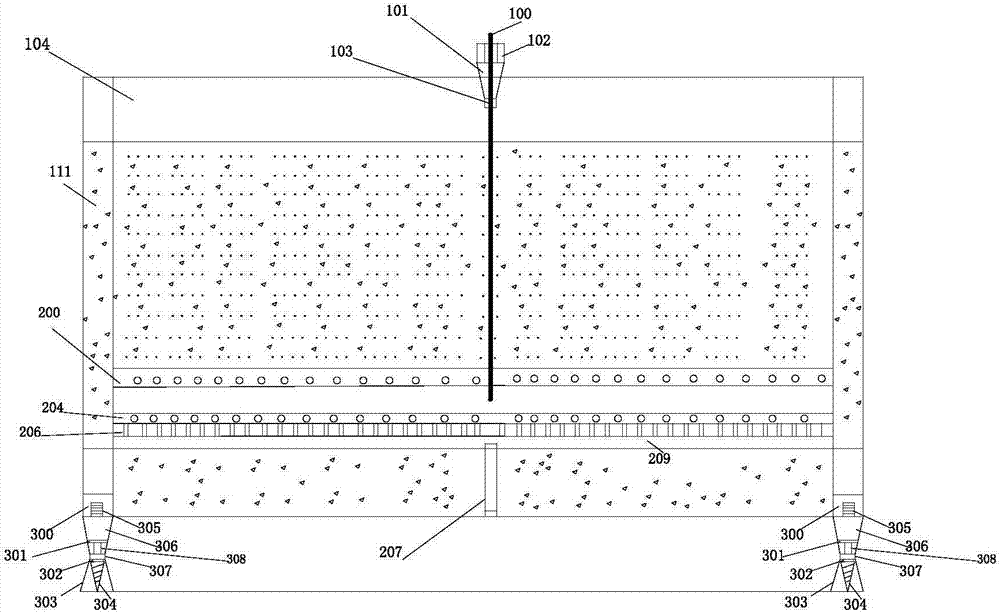

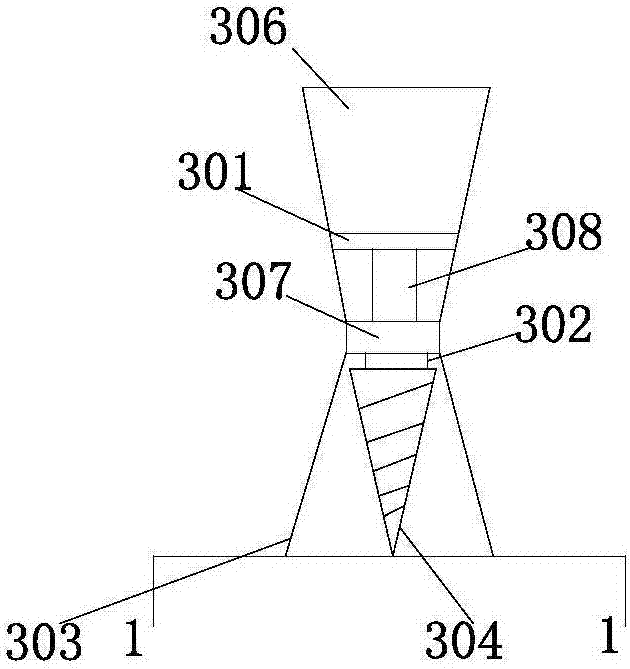

[0024] Such as Figure 1 to Figure 4 as shown in Figure 1 to Figure 4 As shown, a distributed optical fiber monitoring system for seepage flow velocity of a hydraulic structure body of the present invention specifically includes a first soil-rock junction seepage test module, a second soil-rock junction seepage test module, a distributed sensing optical fiber monitoring module, and a soil-rock junction. Joint seepage frame module; distributed sensing optical fiber monitoring module is built in the first soil-rock joint seepage test module and the second soil-rock joint seepage test module, the first soil-rock joint seepage test module and the second soil-rock joint seepage test module Connected by the main frame, the soil-rock joint seepage frame module is distributed at the bottom of the soil-rock joint seepage test module.

[0025] In the present invention, the first soil-rock combination seepage test module includes a 2m-high first frame 111 that constructs the frame stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com