Combustible solid waste utilization composite burner in cement production

A solid waste and burner technology, which is applied in the direction of burners, burners, and combustion methods for burning powder fuels, can solve the problems of large coal consumption, failure to save energy, and failure to save coal, so as to achieve coal saving Effects of energy consumption, reduction of energy consumption, and improvement of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

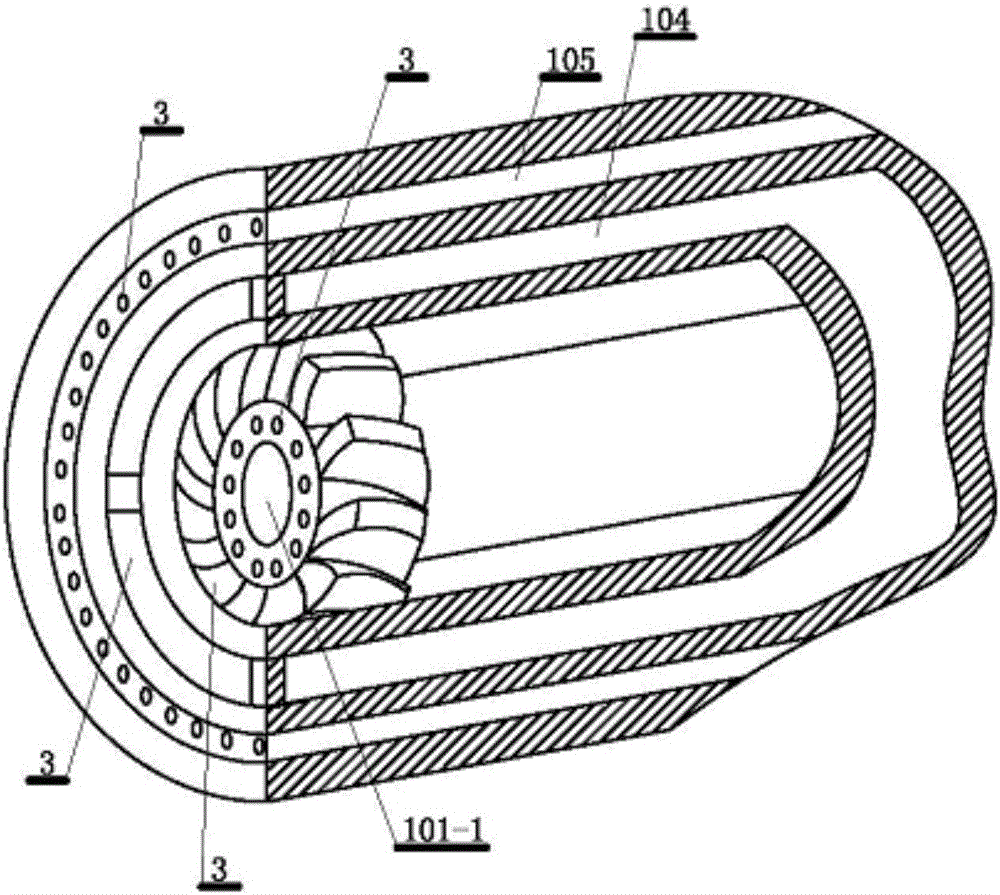

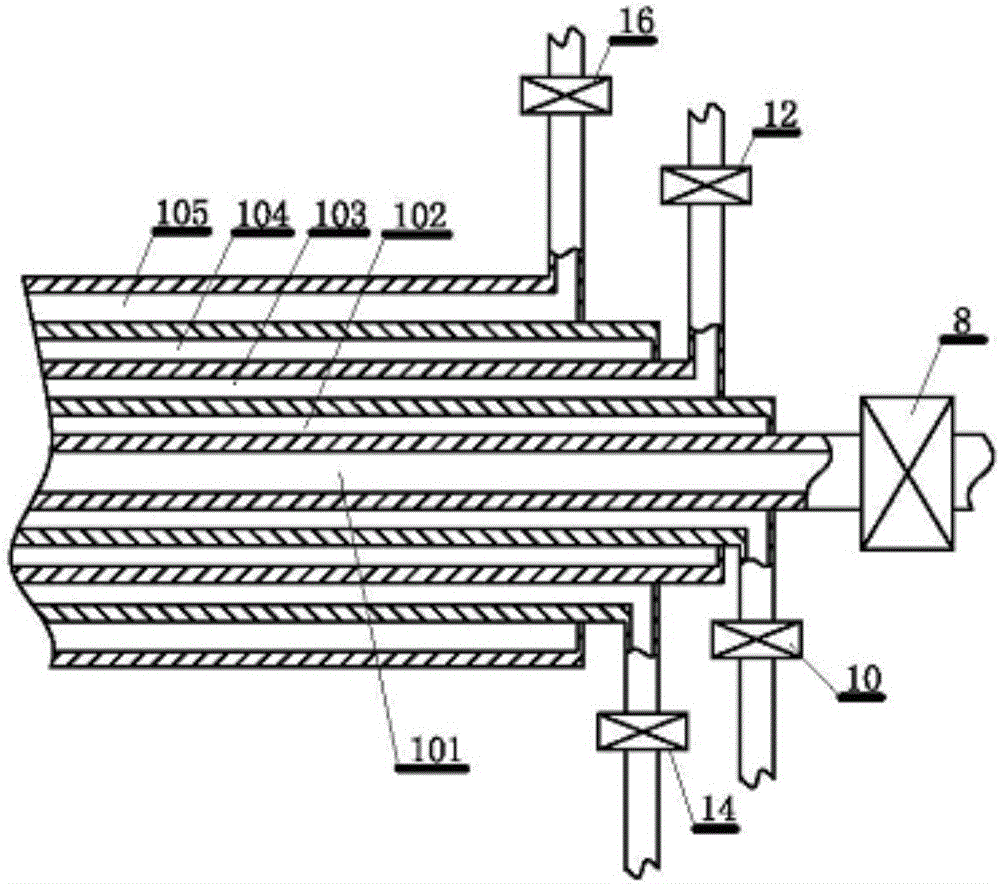

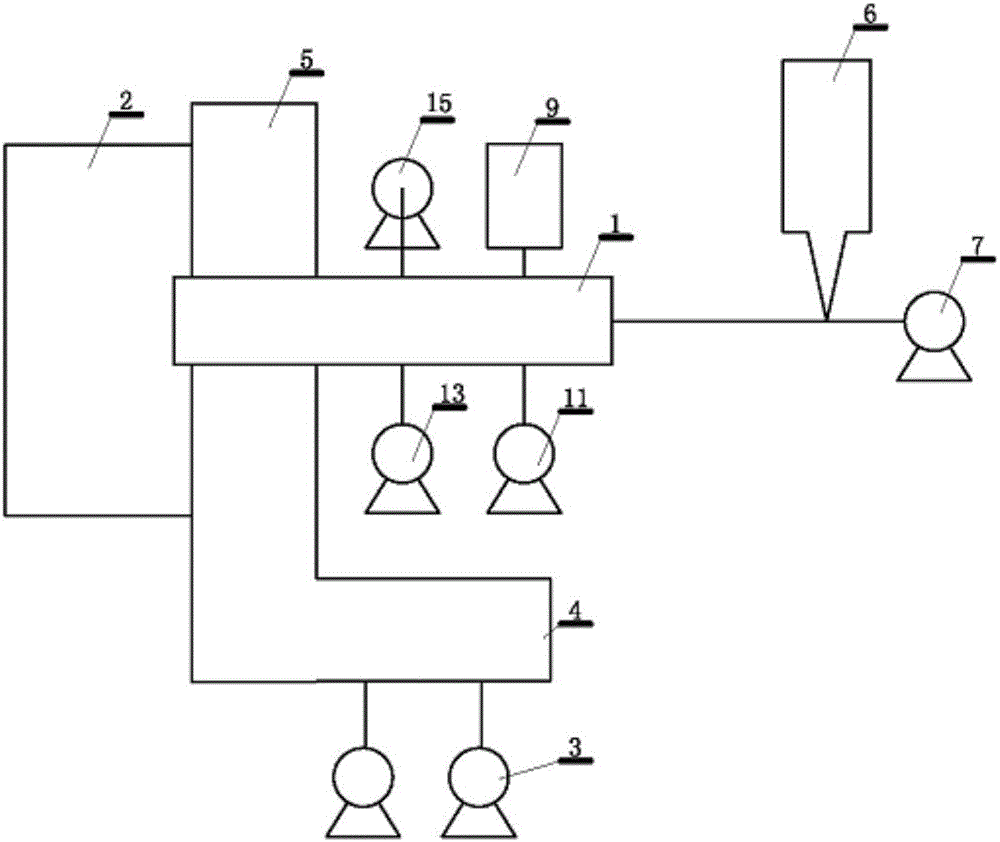

[0020] Combustible solid waste combustion in cement production uses a composite burner. In order to fully utilize the calorific value of urban waste and the need for fuel combustion in cement kilns, the solid waste of urban waste is pretreated and processed into a cement kiln. Combustible powder or granular matter, it is mixed with the currently used coal powder and injected into the cement kiln for combustion, so for the burner using the combustible solid waste powder or particles, it is used as follows in this embodiment image 3 As shown, it is applied in a cement kiln. The burner 1 is set on the kiln head of the cement rotary kiln 2. The centrifugal fan 3 cools the clinker through the grate cooler 4, and provides the second and third air temperatures through the kiln head cover 5; figure 1 with figure 2 As shown, the burner includes a variety of fuel nozzles and fuel delivery pipes connected to the various fuel nozzles, on which a control valve is set and connected to a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com