Device and method for monitoring and controlling residual carbon combustion during hot sintering mineral cooling process

A technology of cooling process and thermal sintering, which is applied in the field of devices for monitoring and controlling residual carbon combustion in the cooling process of hot sintered ore, and in the field of devices for monitoring residual carbon combustion of thermal sintered ore, which can solve problems such as secondary combustion of residual carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0130] According to the second embodiment of the present invention, a method for monitoring and controlling the combustion of residual carbon in the cooling process of hot sintered ore is provided:

[0131] A method for monitoring and controlling the combustion of residual carbon in the cooling process of hot sinter ore or a method for monitoring and controlling the combustion of residual carbon in the cooling process of hot sinter using the above-mentioned device for monitoring and controlling the combustion of residual carbon in the cooling process of hot sinter, the method comprising the following steps :

[0132] 1) The device starts to run, and the first temperature measuring device 5, the first flow detection device 6, the second temperature measuring device 7 and the second flow detection device 8 monitor the temperature and the flow rate of the circulating gas in real time, wherein the first temperature measuring device 5 and the The first flow detection device 6 measu...

Embodiment 1

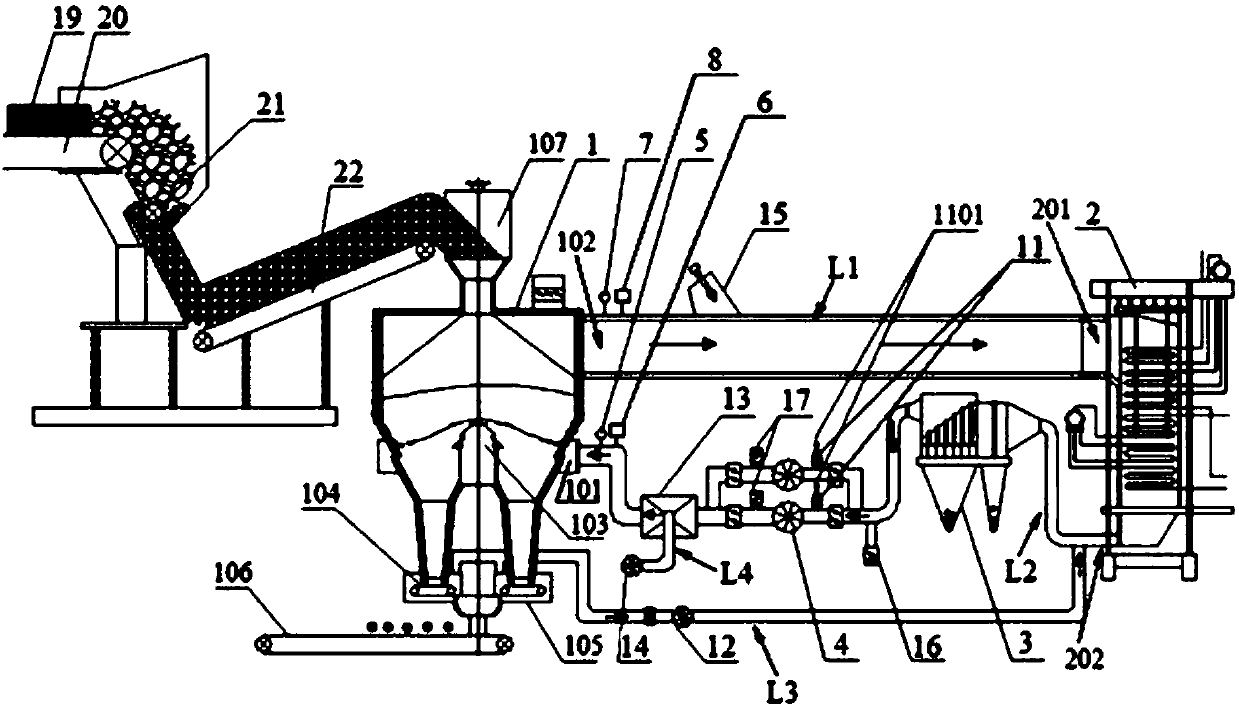

[0192] Such as figure 1 A device for monitoring and controlling residual carbon combustion in the cooling process of hot sintered ore, which includes a vertical cooler 1, a waste heat boiler 2, a dust collector 3 and a circulating fan 4. According to the flue gas flow direction, the high-temperature gas outlet 102 located on the upper part of the tower wall of the vertical cooler 1 is connected to the air inlet 201 of the waste heat boiler 2 through the first pipe L1. The second pipeline L2 drawn from the air outlet 202 of the waste heat boiler 2 is connected to the low-temperature gas inlet 101 located at the lower part of the tower wall of the vertical cooler 1 via the dust collector 3 and the circulating fan 4 . The low temperature gas inlet 101 communicates with the air supply device 103 at the bottom of the tower body of the vertical cooler 1 . The device is provided with a first temperature measuring device 5 and a first flow rate detecting device 6 at the low temperature...

Embodiment 2

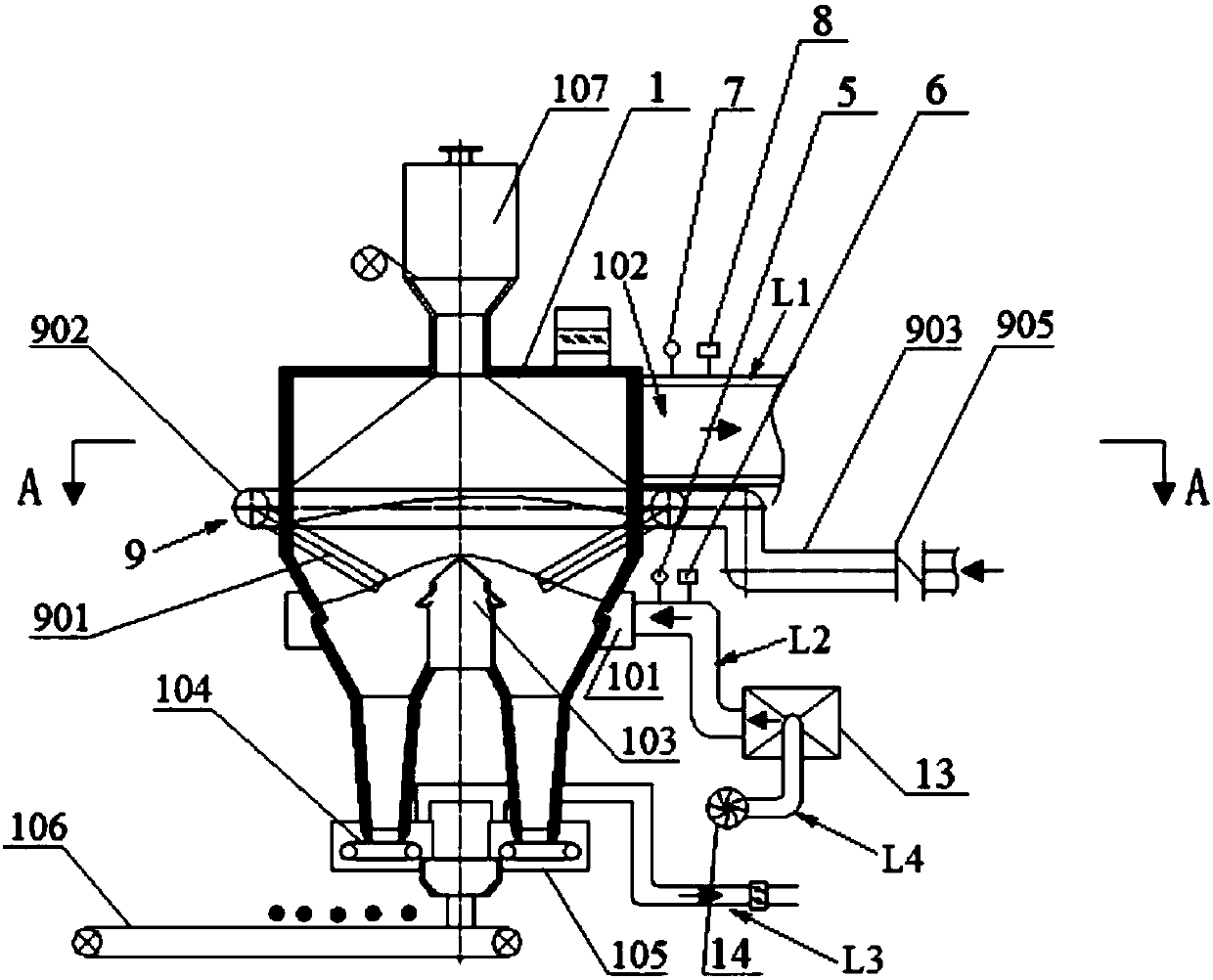

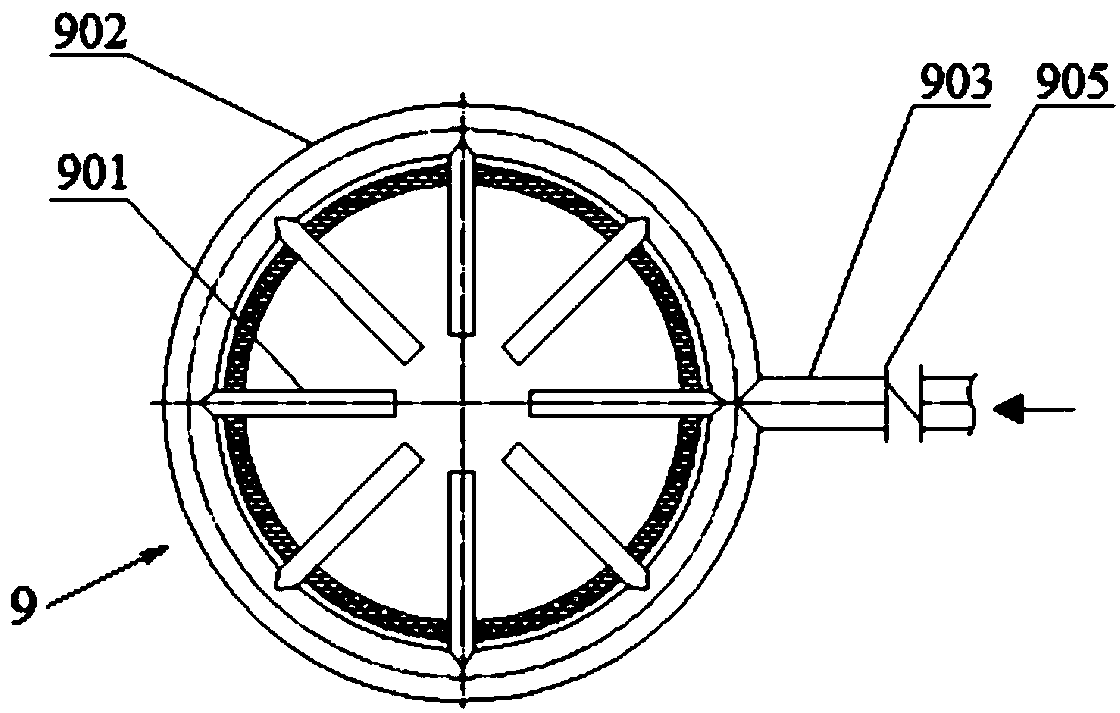

[0201] Such as Figure 2-5 A device for monitoring and controlling residual carbon combustion in the cooling process of hot sintered ore, which includes a vertical cooler 1, a waste heat boiler 2, a dust collector 3 and a circulating fan 4. According to the flue gas flow direction, the high-temperature gas outlet 102 located on the upper part of the tower wall of the vertical cooler 1 is connected to the air inlet 201 of the waste heat boiler 2 through the first pipe L1. The second pipeline L2 drawn from the air outlet 202 of the waste heat boiler 2 is connected to the low-temperature gas inlet 101 located at the lower part of the tower wall of the vertical cooler 1 via the dust collector 3 and the circulating fan 4 . The low temperature gas inlet 101 communicates with the air supply device 103 at the bottom of the tower body of the vertical cooler 1 . The device is provided with a first temperature measuring device 5 and a first flow rate detecting device 6 at the low temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com