Automatic control strategy and method for load of biomass water-cooled vibrating grate boiler

A technology of vibrating grate and boiler load, which is applied in the control system, combustion method, and control of combustion, etc., can solve the problems of lack of automatic adjustment and control of biomass water-cooled vibrating grate boiler load, reduce labor intensity, improve automation level, The effect of precise and timely adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

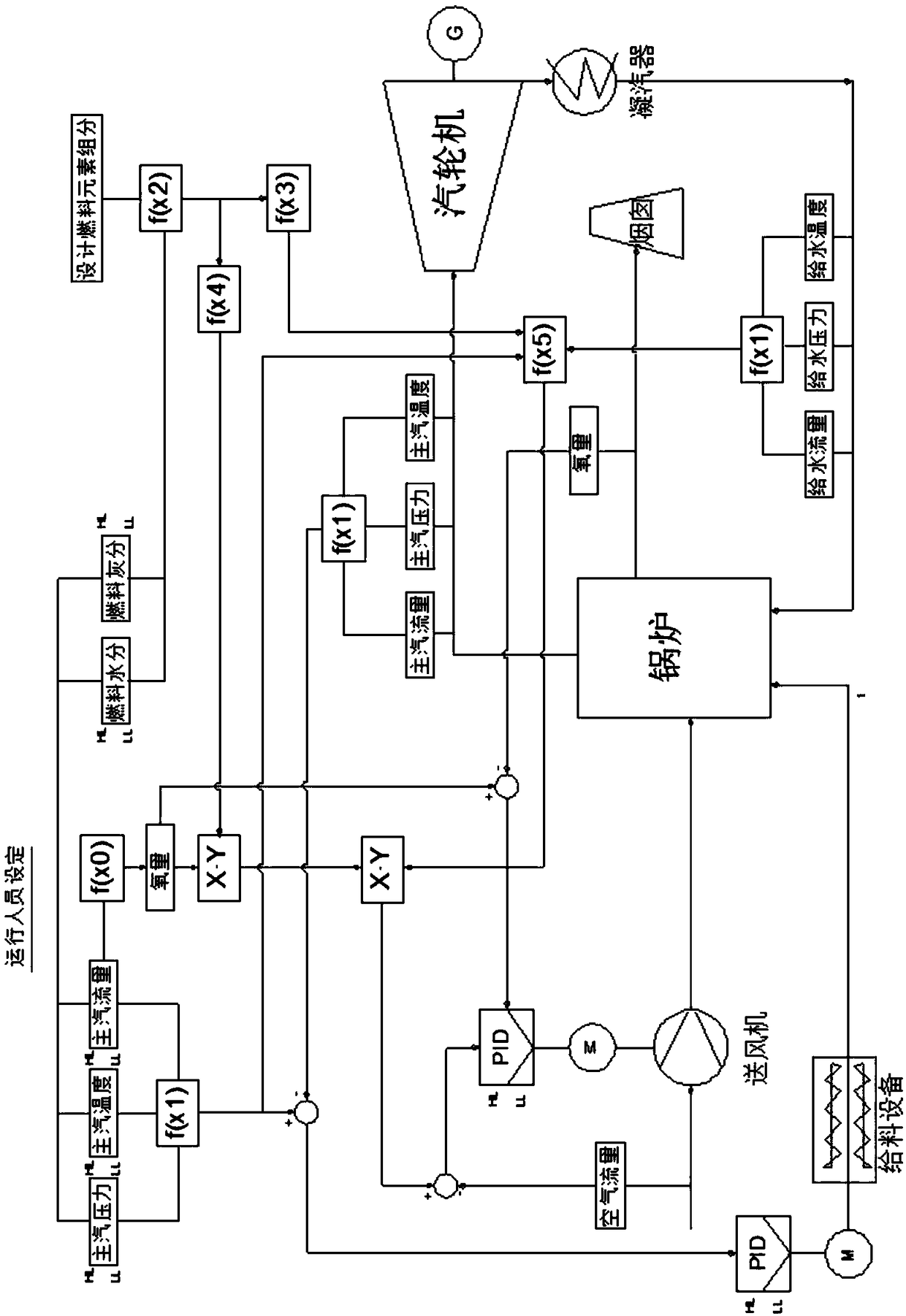

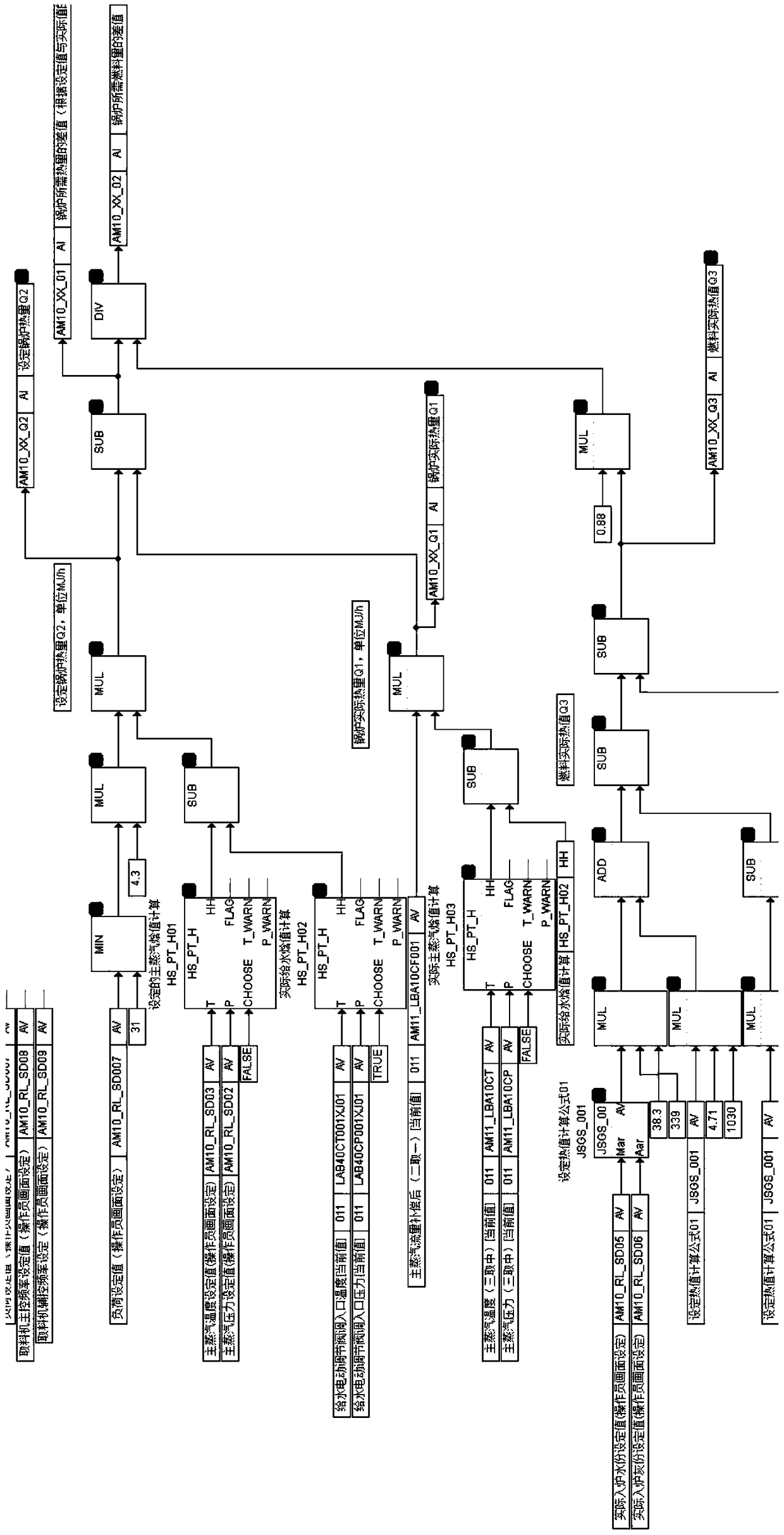

[0049] as attached Figure 1-Figure 3 As shown, a dialog box is set on the DCS screen that can be manually set by the operator, including main steam flow, main steam pressure, main steam temperature, fuel moisture and fuel ash. In the configuration logic, the upper limit and lower limit functions are used to judge the validity of the numerical value input by the operator. Operators convert the active power into the main steam flow according to the steam consumption rate of the steam turbine generator set, and use the moisture and ash content of the industrial analysis of the actual fuel into the furnace as the fuel moisture and ash content.

[0050] According to the boiler design specification or operation adjustment test, the optimal oxygen value under different loads (main steam flow) can be obtained. Therefore, the oxygen value under different loads is calculated by the broken line function f(x0).

[0051] The set values of main steam flow, main steam pressure and main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com