Segmented convergence type double-S-curve binary mixed exhaust system

An exhaust system and binary mixing technology, which is applied in jet propulsion devices, machines/engines, etc., can solve the problems of large nozzle size and severe separation of central cone airflow, and achieve small lateral size, improved aerodynamic performance, and suppressed separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

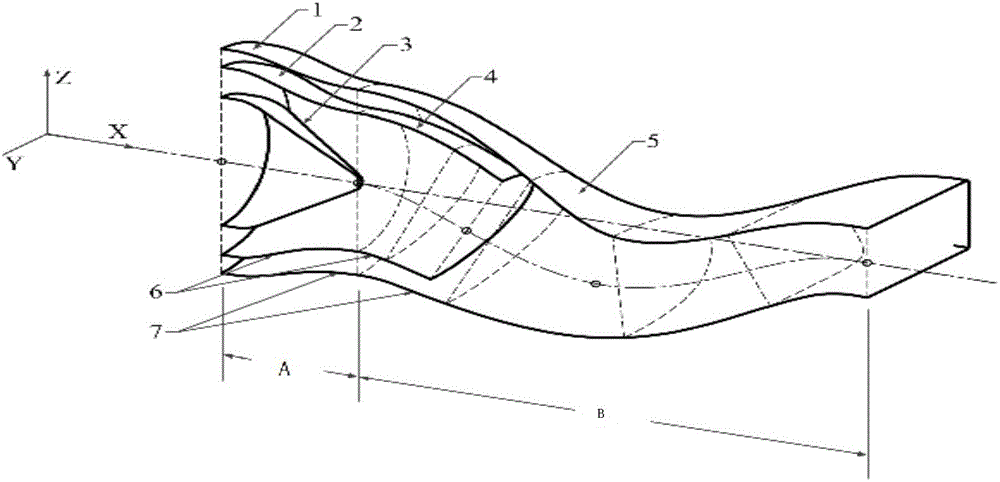

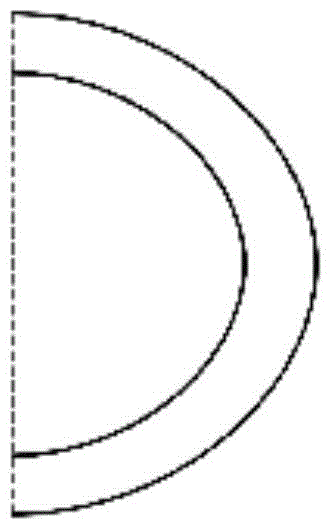

[0028] figure 1 It is a schematic diagram of the 1 / 2 physical model of the segmented and convergent double S-curved binary hybrid exhaust system designed by the present invention. The engine axis is along the X-axis in the coordinate system, and the exhaust system is axisymmetric with the engine axis first. It gradually converges along the axis of the engine (section A in the figure), and then gradually converges in a double S-curved shape along the axis of the engine (section B in the figure), consisting of the outer axisymmetric convergence section 1, the inner axisymmetric convergence section 2, The conical central cone 3, the inner S-curve convergent section 4 and the outer double-S-curve binary convergent section 5 are composed, and the inner axisymmetric convergent section 2 and the inner S-curve convergent section 4 are connected to form the inner wall 6 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com