Fireproof heat-preservation waterproof anti-crack reflective heat insulation material system and construction process thereof

A technology of thermal insulation material, fire prevention and thermal insulation, applied in the direction of floor, covering/lining, construction, etc., can solve the problems of falling insulation board, people injury, etc., to achieve the effect of firm fixing, prolonging service life and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

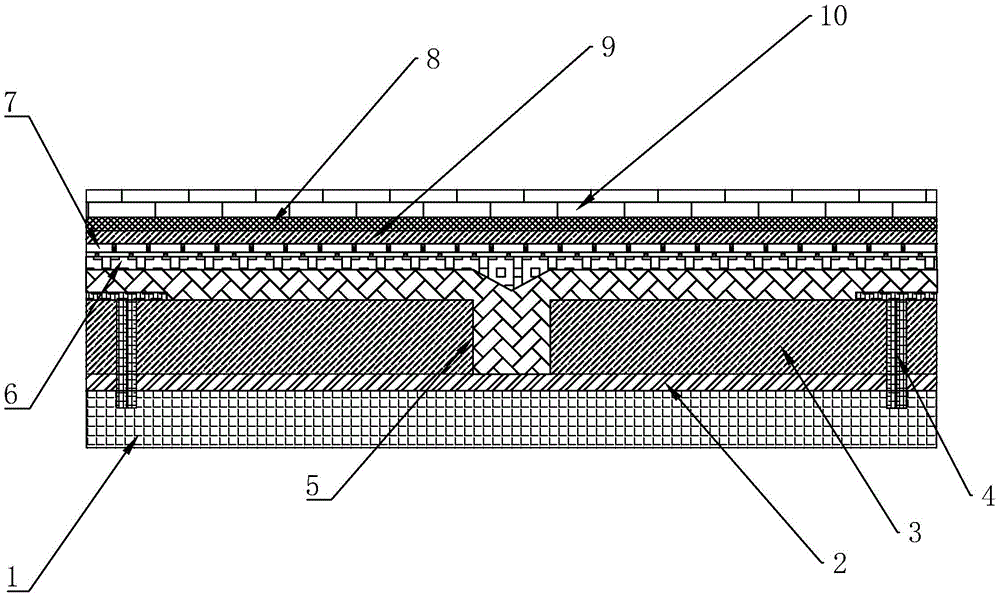

[0029] S1, adding 11 parts by weight of brominated polystyrene and 1.5 parts by weight of potassium sorbate to silicone resin glue 2 with 31 parts by weight for uniform mixing; S2, the obtained Smear the silicone resin glue 2 evenly on the construction wall surface 1; S3, paste the insulation board 3 on the construction wall surface 1, and fix the insulation board 3 and the construction wall surface 1 with rivets 4; S4, attach S3 Some insulation boards 3 attached to the construction wall are fixedly connected by insulation board brackets 11; Also fill in the gap between the adjacent insulation boards 3, and become the division seam 6 of the insulation board 3, simultaneously, make the flexible putty dry naturally for 4 hours; Lay the reflective heat insulation layer 7; S7, brush the TPV layer 8 on the reflective heat insulation layer 7, and spread the anti-ultraviolet nylon fiber layer 10 before the TPV is dry, and then use ABS on the anti-ultraviolet nylon fiber layer 10 Lay...

Embodiment 2

[0031] S1, adding 15 parts by weight of brominated polystyrene, and 2.3 parts by weight of potassium sorbate in silicone resin glue 2 with 36 parts by weight for uniform mixing; S2, the obtained by S1 Smear the silicone resin glue 2 evenly on the construction wall surface 1; S3, paste the insulation board 3 on the construction wall surface 1, and nail the insulation board 3 into the center of the construction wall surface 1 with rivets 4 Fixing; S4, a number of insulation boards 3 attached to the construction wall in S3 are fixedly connected with insulation board brackets 11; S5, on the wall surface of the insulation boards 3 attached in S4, evenly apply the flexible putty layer 5 , the flexible putty also fills the gap between the adjacent insulation boards 3, and becomes the division seam 6 of the insulation board 3, at the same time, the flexible putty is naturally dried for 4 hours; Cover the reflective insulation layer 7 on the putty layer 5; S7, brush the TPV layer 8 on ...

Embodiment 3

[0033]S1, adding 13 parts by weight of brominated polystyrene and 1.9 parts by weight of potassium sorbate to silicone resin glue 2 with 33 parts by weight for uniform mixing; S2, the obtained Smear the silicone resin glue 2 evenly on the construction wall surface 1; S3, paste the insulation board 3 on the construction wall surface 1, and nail the insulation board 3 into the center of the construction wall surface 1 with rivets 4 Fixing; S4, a number of insulation boards 3 attached to the construction wall in S3 are fixedly connected with insulation board brackets 11; S5, on the wall surface of the insulation boards 3 attached in S4, evenly apply the flexible putty layer 5 , the flexible putty also fills the gap between the adjacent insulation boards 3, and becomes the division seam 6 of the insulation board 3, at the same time, the flexible putty is naturally dried for 4 hours; Cover the reflective insulation layer 7 on the putty layer 5; S7, brush the TPV layer 8 on the refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com