A method suitable for dry-stacking fine-grained tailings on flat land or beside mountains

A technology for fine-grained tailings and tailings, which is used in tailings disposal, dry heap disposal of fine-grained tailings in rainy areas in southern my country, and can solve the problem of high construction and operating costs, and the small amount of fine-grained tailings treated by filter press technology. , not suitable for large-scale dry heap application of fine-grained tailings, etc., to achieve the effect of improving safety margin, reducing chemical consumption, saving construction investment and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further describe the present invention, a method for dry-stacking fine-grained tailings in the present invention will be further described in conjunction with the accompanying drawings and examples below.

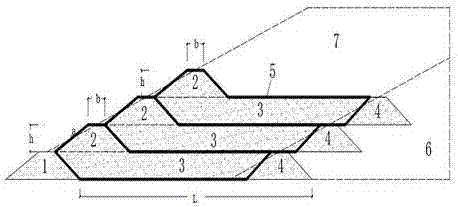

[0031] Depend on figure 1 The stacking schematic diagram of a method suitable for dry stacking of fine tailings in the present invention is shown, and it can be seen that a method of dry stacking of fine tailings in the present invention is suitable for dry stacking of fine tailings in flat land or beside mountains. The method is to determine the site according to the mine planning requirements, and understand the engineering geology and hydrogeological conditions of the tailings dry storage site through the investigation of the tailings dry storage site; and then according to the concentration and particle size of the tailings discharged from the concentrator The distribution and mineral composition are determined through the ratio test to determine the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com