Anticorrosion antistatic coating and preparation method thereof

A technology of static electricity and corrosion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The synthesis process of nano zinc oxide fiber is as follows:

[0031] 1mol / LZn(CH 3 COO) 2 The solution was put into a beaker as a precursor, and the NaNO 2 Add to the precursor, continue magnetic stirring and slowly add NaNO 2 When the final concentration is 3mol / L, stop the dropwise addition and transfer the above solution to an autoclave with a polytetrafluoroethylene liner to keep its filling degree at 80%. React at a constant temperature of 190 degrees Celsius for 1 hour, open the valve to release the pressure under high pressure, and cut off the power supply to allow the autoclave to cool naturally to room temperature. Suction filter and collect the white precipitate. Rinse repeatedly with deionized water to remove excess ions, and dry in a vacuum oven at 90 °C.

[0032] The nano zinc oxide prepared by this method is fiber type, and the aspect ratio is 16:1.

Embodiment 2

[0034] The raw material components of an anti-corrosion and anti-static coating are: styrene-acrylic emulsion 25-30%, nanometer zinc oxide fiber 0.2-10%, zinc phosphate 15-20%, conductive mica powder 10-15%, conductive Zinc oxide 5-10%, paint additives 2-5%, deionized water 15-25%. The coating additives include by mass parts: 0.3-0.5% of NXZ defoamer, 2-3% of ethylene glycol, 0.3-0.5% of 2020 leveling agent and 3-4% of TEXANOL1321 film-forming aid.

Embodiment 3

[0036] Synthesis of heat-reflective heat-insulating anti-corrosion coatings:

[0037] Weigh 1 gram of nano-zinc oxide fiber prepared according to the method in Example 1, add 100 grams of deionized water to prepare a mixed solution. In the state of magnetic stirring, add 1 g of NXZ defoamer, 7.5 g of ethylene glycol, 65 g of zinc phosphate, 45 g of conductive mica powder and 20 g of conductive zinc oxide in sequence. 1000r / min high-speed stirring and dispersing for 1 hour, grinding for 10-20 minutes, ultrasonic dispersion and stirring for 20-30 minutes to obtain pigment and filler slurry.

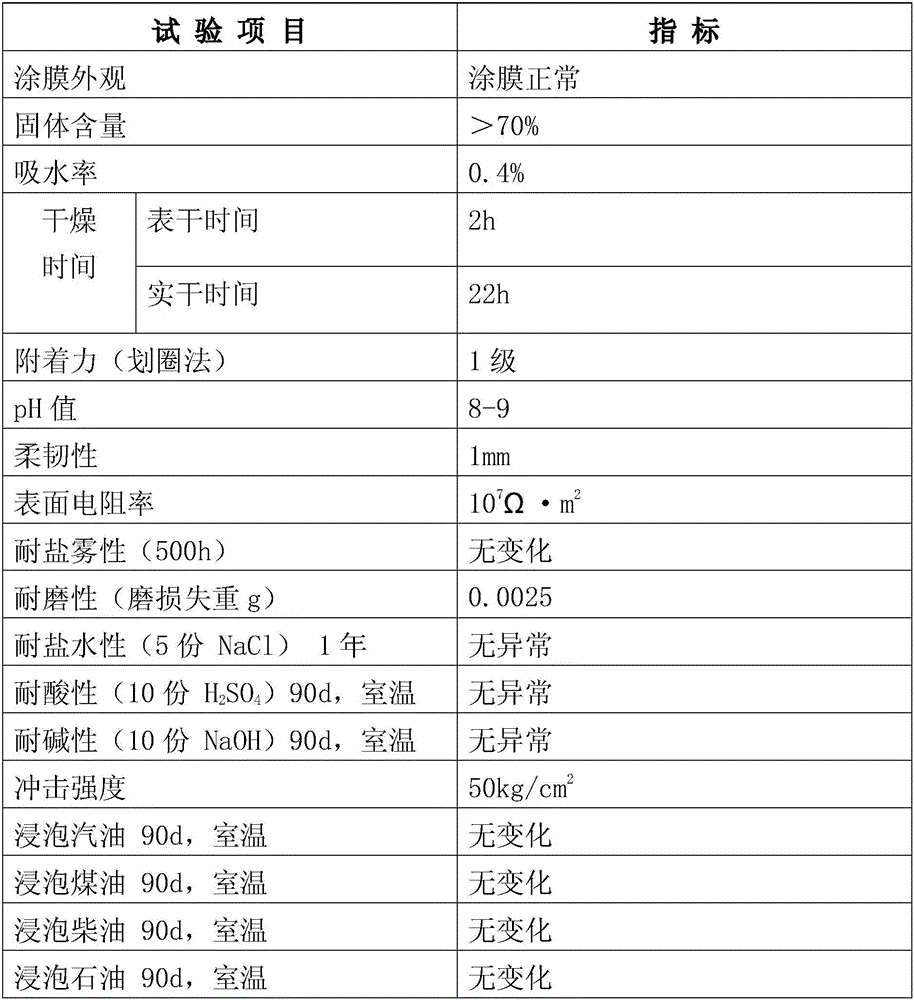

[0038] Take 210 grams of the above slurry and add 90 grams of styrene-acrylic emulsion, and then add 1 gram of NXZ defoamer, 1.5 grams of 2020 leveling agent, and 5 grams of TEXANOL1321 film-forming aid under low-speed stirring at 300-500 r / min, and add ammonia water dropwise to adjust the pH Value to 8-9. After stirring evenly for 20 minutes, slowly add 0.2 g of ATE-431 thickener to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com