Novel environmental-aging-resistant PP material and preparation method thereof

An environment-resistant and new technology, applied in the field of new environment-resistant aging PP materials and its preparation, can solve the problems of loss of mechanical properties, frosting, increase of TVOC content of materials, etc., reduce precipitation and emission problems, simple production process, easy The effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

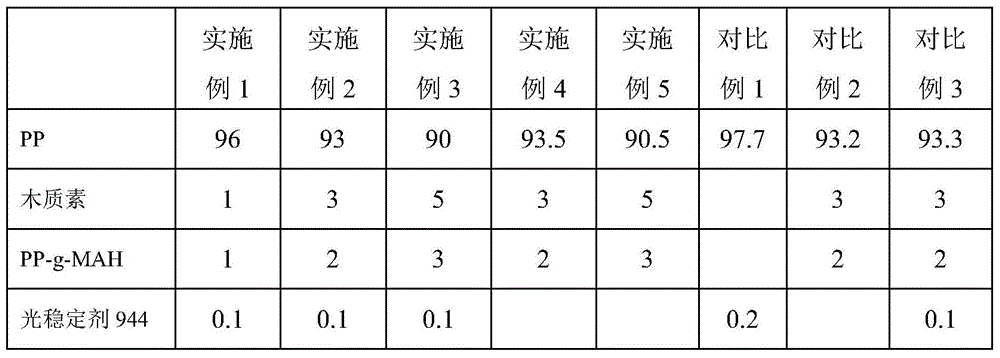

[0021] In the PP material formulations of Examples and Comparative Examples, PP is M2600R produced by Shanghai Petrochemical Company. The lignin used is wood pulp lignin without any modification treatment and is self-made. PP-g-MAH is self-made, and the grafting rate is 1%. The light stabilizers are 944 and 770 produced by Ciba Company. The main antioxidant is selected from Irganox1010 produced by Ciba Company. The secondary antioxidant is selected from Irganos168 produced by Ciba Company.

[0022] Dry mix various raw materials and additives in a high-speed mixer for 5 to 15 minutes; put the uniformly mixed raw materials into a twin-screw extruder, melt and extrude, cool and granulate to obtain PP materials, and the process is a zone 190~ 200°C, 200-210°C in the second zone, 195-200°C in the third zone, 205-215°C in the fourth zone, the residence time of the whole extrusion process is 1-2 minutes, and the pressure is 12-18MPa.

[0023] Performance evaluation methods and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com