Laminarin and extraction and separation method thereof

A technology of kelp polysaccharide and separation method, which is applied in the directions of pharmaceutical formulations, organic active ingredients, medical preparations containing active ingredients, etc., can solve problems such as unseen and rare single polysaccharide components, and achieve the effect of uniform molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for separating and extracting laminarin, the specific steps are:

[0024] 1) Take 60g of kelp dry powder, add 1.5L of absolute ethanol, bathe in water at 50°C for 4 hours, filter, collect the filter residue, and let it stand at room temperature and air-dry to obtain decolorized kelp dry powder;

[0025] 2) Take 50g of decolorized kelp dry powder, add 2.75L of ultrapure water, place it in an autoclave, the pressure is 0.1MPa, and the treatment time is 50min; filter, collect the filtrate and concentrate to 600mL;

[0026] 3) Add absolute ethanol to adjust the final volume concentration of ethanol to 25%, 50%, and 75%, carry out graded precipitation, collect ethanol precipitates with a volume concentration of 75%, and dry to obtain laminarin crude extract with a yield of 3.5%;

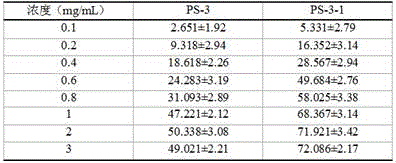

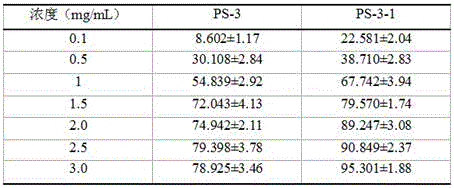

[0027] 4) Dissolve the crude polysaccharide extract in 0.02mol / L Tris-HCl buffer (pH7.5), and separate it by DEAE-Sephadex anion exchange chromatography. The eluent is Tris-HCl buffer cont...

Embodiment 2

[0032] A method for separating and extracting laminarin, the specific steps are:

[0033] 1) Take 60g of kelp dry powder, add 1.5L of absolute ethanol, bathe in water at 50°C for 4 hours, filter, collect the filter residue, and let it stand at room temperature and air-dry to obtain decolorized kelp dry powder;

[0034] 2) Take 50g of decolorized kelp dry powder, add 3.5L of ultrapure water, put it in an autoclave, the pressure is 0.14MPa, the treatment time is 60min, filter, collect the filtrate and concentrate to a volume of 1000mL;

[0035] 3) Add absolute ethanol to adjust the final volume concentration of ethanol to 25%, 50%, and 75%, carry out fractional precipitation, collect 75% ethanol precipitate, and dry to obtain laminarin crude extract, with a yield of 3.6%;

[0036] 4) Dissolve the crude polysaccharide extract in 0.02mol / L Tris-HCl buffer (pH 7.5), and separate it by DEAE-Sephadex ion exchange chromatography. The eluent is Tris-HCl buffer containing 1mol / L NaCl. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com