Calcium citrate salt and preparation method and application thereof

A technology of calcium citrate salt and application, applied in the directions of carboxylate preparation, food preparation, cyanide reaction preparation, etc., can solve the technical enlightenment and single problem of not giving a variety of alkyl L-carnitine salts , to achieve strong and more functional nutrition and therapeutic effects, suitable for oral administration, easy storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

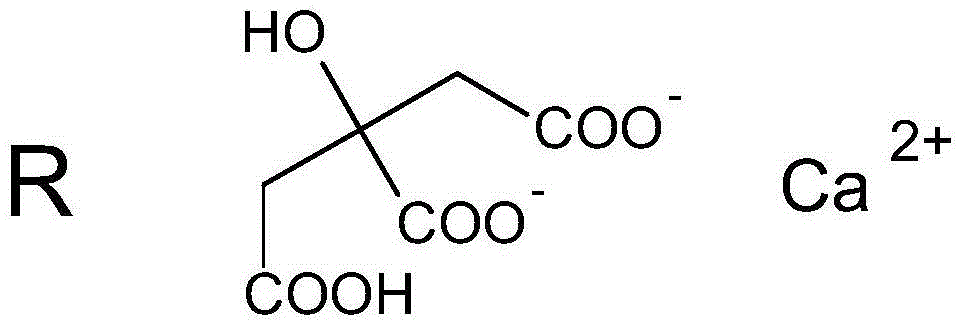

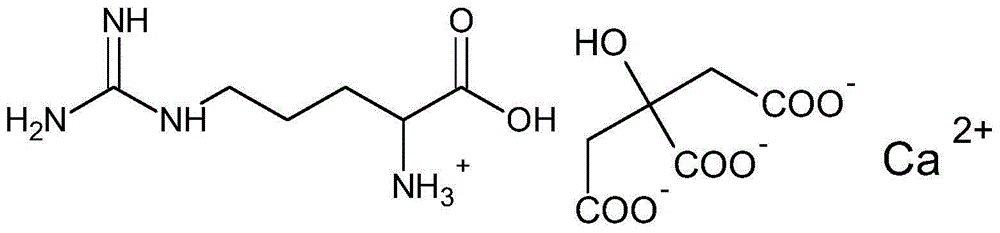

[0038] Example 1: Preparation of L-arginine calcium citrate salt.

[0039]

[0040] Dissolve 21 grams (0.1 mol) of citric acid monohydrate in 200 ml of water, add 7.4 grams (0.1 mol) of calcium hydroxide, dissolve at room temperature, filter the solution after it is transparent, and remove SiO in calcium hydroxide 2 Wait for impurities, add 17.4 grams (0.1mol) of L-arginine to the clean filtrate, stir and react at 70-80°C for 4 hours, then concentrate, add absolute ethanol to crystallize after cooling down, filter and dry, and the obtained L-arginine Amino acid citrate calcium salt 38.8 grams, has good fluidity and anti-hygroscopicity, yield 96.0%.

[0041] [α] D 20 =+10.8° (C=1,0.5NHCl), L-arginine HPLC content 42.4%, citric acid HPLC content 47.0%, calcium content 9.7%.

Embodiment 2

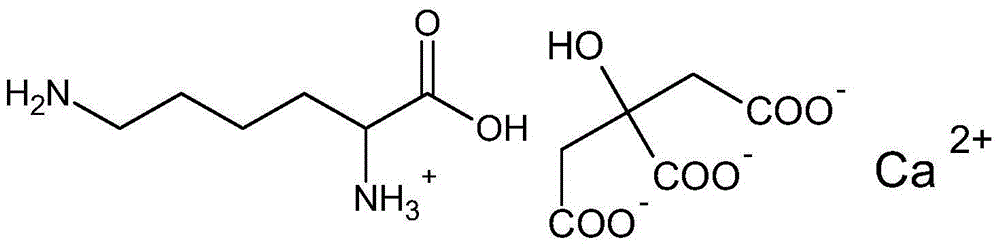

[0042] Embodiment 2: Preparation of calcium salt of L-lysine citrate.

[0043]

[0044] Dissolve 21 grams (0.1mol) of citric acid monohydrate in 200ml water, add 5.6 grams (0.1mol) of calcium oxide, dissolve at room temperature, filter the solution after it is transparent, and remove SiO in calcium oxide 2 Wait for impurities, add 14.6 grams (0.1mol) of L-lysine to the clean filtrate, stir and react at 70-80°C for 4 hours, then concentrate, add absolute ethanol to crystallize after cooling down, filter and dry, and the obtained L-lysine Amino acid citrate calcium salt 36.5 grams, has good fluidity and anti-hygroscopicity, yield 97.1%.

[0045] [α] D 20 =+8.8°(C=1,0.5NHCl), L-lysine HPLC content 39.4%, citric acid HPLC content 50.2%, calcium content 10.0%.

Embodiment 3

[0046] Example 3: Preparation of acetyl L-carnitine citrate calcium salt.

[0047]

[0048] Dissolve 21 grams (0.1mol) of citric acid monohydrate in 200ml of water, add 10.0 grams (0.1mol) of calcium carbonate, dissolve at room temperature, filter the solution after it is transparent, and remove SiO in calcium carbonate 2 Wait for impurities, add 20.3 g (0.1 mol) of acetyl L-carnitine to the clean filtrate, stir and react at 70-80°C for 4 hours, then concentrate, add absolute ethanol to crystallize after cooling down, filter and dry, the obtained acetyl L-carnitine 41.5 grams of carnitine citrate calcium salt has good fluidity and moisture absorption resistance, and the yield is 95.8%.

[0049] [α] D 20 =-12.2° (C=1,0.5NHCl), acetyl L-carnitine HPLC content 45.9%, citric acid HPLC content 45.2%, calcium content 8.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com