Method for preparing BaTiO3 ceramic

A technology of ceramics and crystals, applied in the field of preparation and application of electronic ceramics, can solve the problems of cumbersome steps and long reaction time, and achieve the effect of simple process, simple method and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing BTO ceramics. The preparation method uses barium acetylacetonate and titanyl acetylacetonate as raw materials, and uses absolute ethanol as a solvent to obtain BTO crystal powder through low-temperature calcination, and obtain BTO through high-temperature sintering after tableting. Ceramics, specifically comprising the following steps:

[0022] (1) Weigh 0.01mol of Ba(acac) 2 and 0.01mol of TiO(acac) 2 , added to 10ml of absolute ethanol, stirred vigorously with a magnetic stirrer to obtain a mixed solution;

[0023] (2) drying the mixed solution at 80° C. for 15 hours to obtain a dry product;

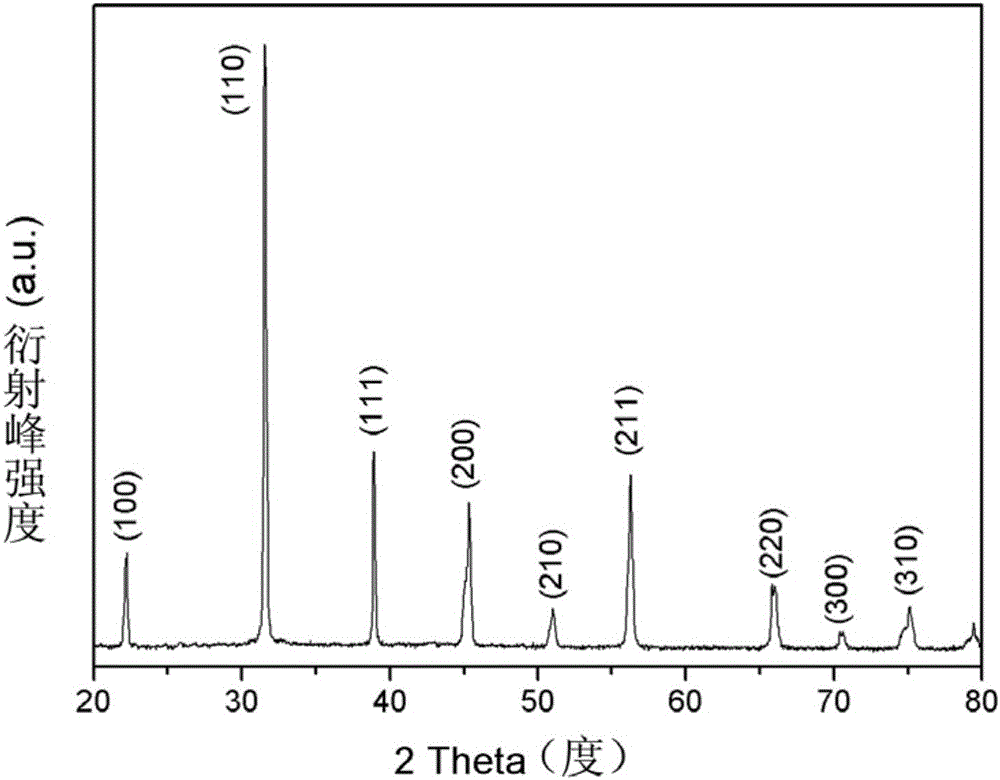

[0024] (3) Fully grind the dried product, then raise the temperature to 500°C at a rate of 20°C / min, and keep it warm for 2 hours to obtain BTO crystal powder;

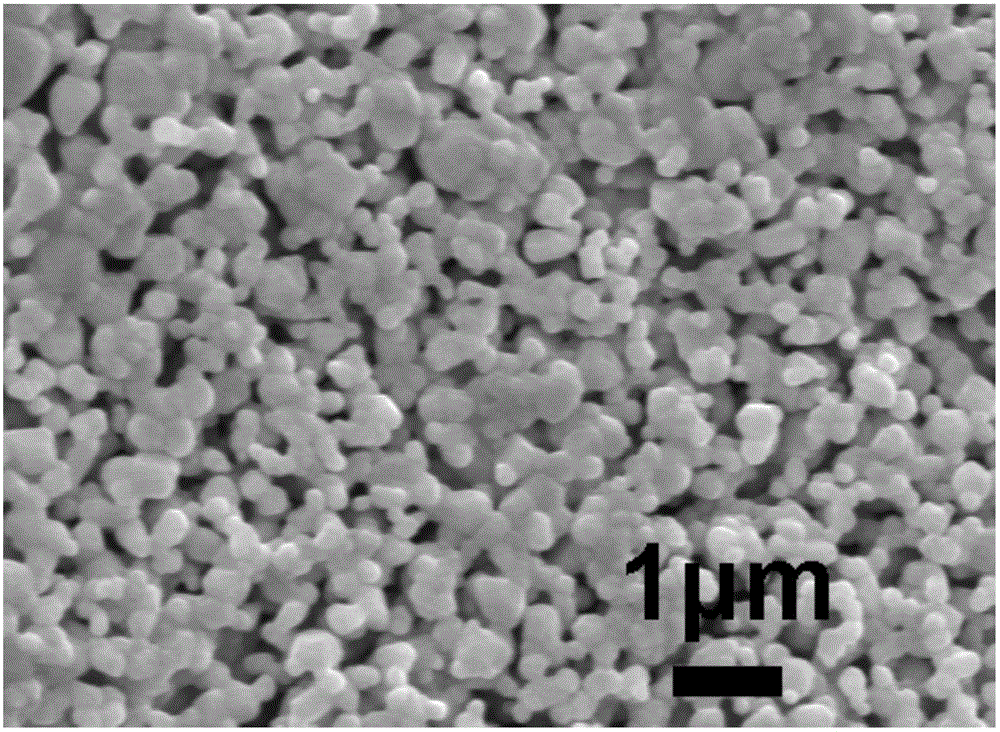

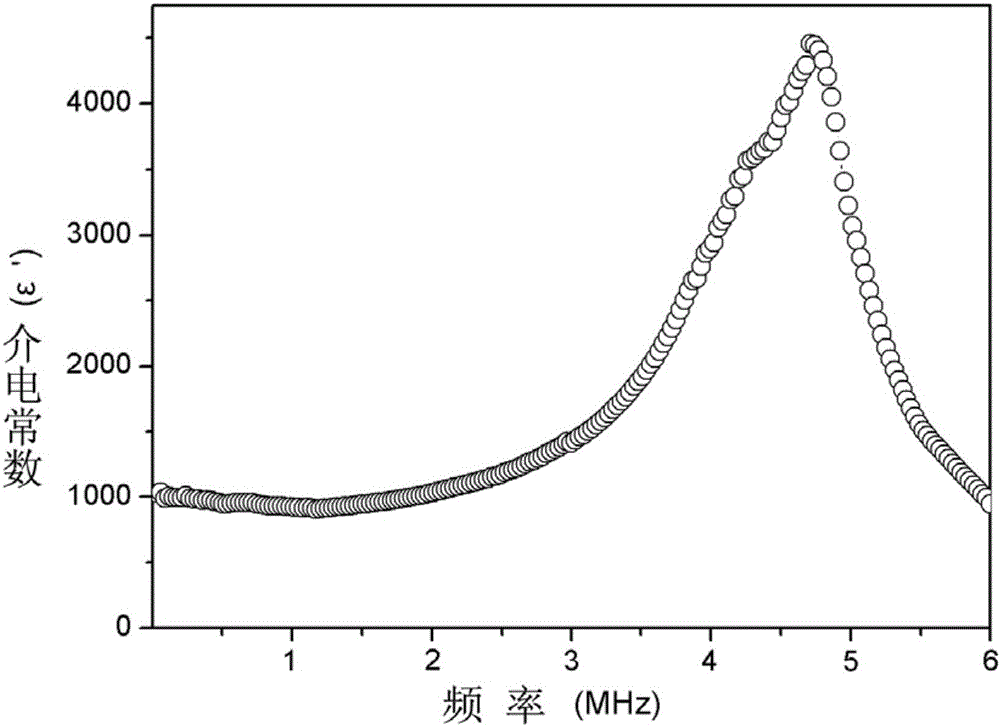

[0025] (4) Press the BTO crystal powder into tablets under a pressure of 20 MPa, then raise the temperature to 1000° C. at a rate of 20° C. / min, and keep the temperature for 5 hours to obtain B...

Embodiment 2

[0030] A method for preparing BTO ceramics. The preparation method uses barium acetylacetonate and titanyl acetylacetonate as raw materials, and uses absolute ethanol as a solvent to obtain BTO crystal powder through low-temperature calcination, and obtain BTO through high-temperature sintering after tableting. Ceramics, specifically comprising the following steps:

[0031] (1) Weigh 0.02mol of Ba(acac) 2 and 0.02mol of TiO(acac) 2 , added to 15ml of absolute ethanol, stirred vigorously with a magnetic stirrer to obtain a mixed solution;

[0032] (2) drying the mixed solution at 85° C. for 15 hours to obtain a dry product;

[0033] (3) Fully grind the dried product, then raise the temperature to 400°C at a rate of 15°C / min, and keep it warm for 2.5h to obtain BTO crystal powder;

[0034] (4) Press the BTO crystal powder into tablets under a pressure of 15 MPa, then raise the temperature to 800° C. at a rate of 15° C. / min, and keep it for 10 hours to obtain BTO ceramics.

Embodiment 3

[0036] A method for preparing BTO ceramics. The preparation method uses barium acetylacetonate and titanyl acetylacetonate as raw materials, and uses absolute ethanol as a solvent to obtain BTO crystal powder through low-temperature calcination, and obtain BTO through high-temperature sintering after tableting. Ceramics, specifically comprising the following steps:

[0037] (1) Weigh 0.03mol of Ba(acac) 2 and 0.03mol of TiO(acac) 2 , add 20ml of absolute ethanol, and stir vigorously with a magnetic stirrer to obtain a mixed solution;

[0038] (2) drying the mixed solution at 90°C for 10 hours to obtain a dry product;

[0039] (3) Fully grind the dried product, then raise the temperature to 600°C at a rate of 25°C / min, and keep it warm for 1.5h to obtain BTO crystal powder;

[0040] (4) Press the BTO crystal powder into tablets under a pressure of 10 MPa, then raise the temperature to 1250° C. at a rate of 25° C. / min, and keep it for 2 hours to obtain BTO ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com