Stainless steel liquid waste regeneration system based on spray roasting method and control method thereof

A technology of spray roasting method and regeneration system is applied in the field of stainless steel waste liquid regeneration system and its control. Conducive to the heat exchange effect and the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0039] The invention proposes a stainless steel waste liquid regeneration system based on a spray roasting method.

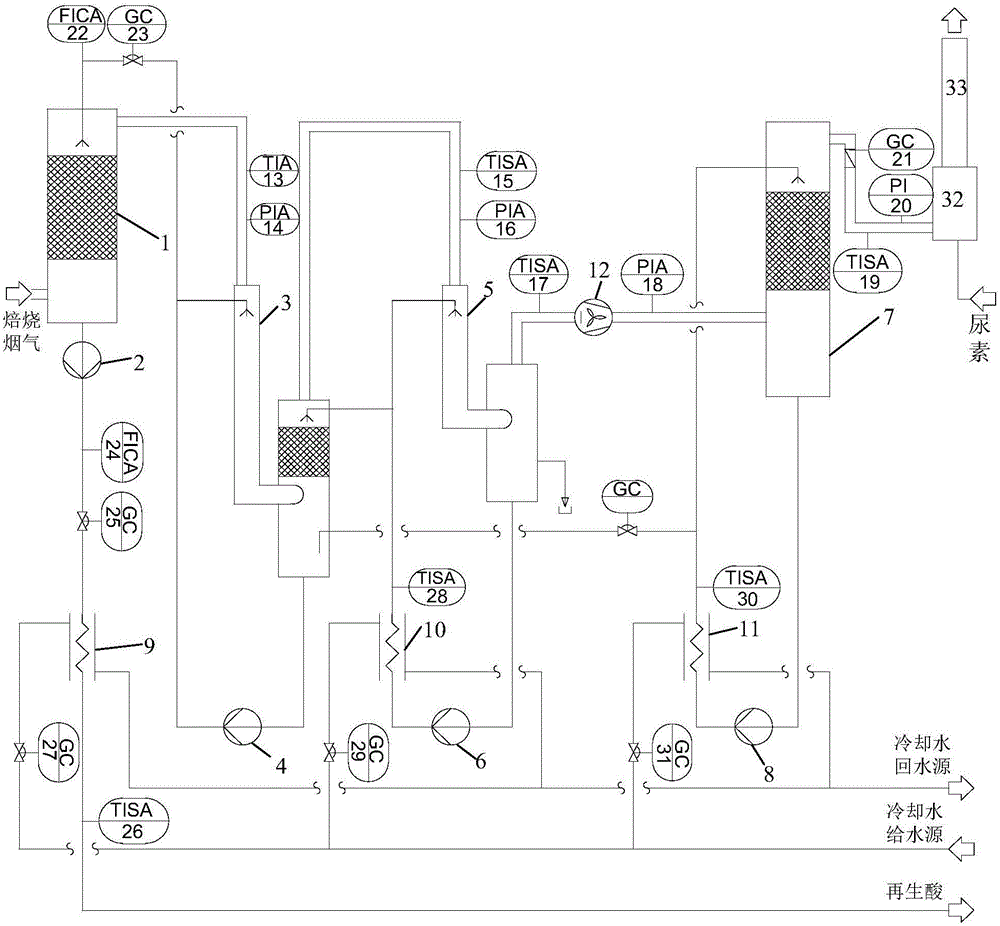

[0040] refer to figure 1 , figure 1 It is a structural schematic diagram of a preferred embodiment of the stainless steel waste liquid regeneration system based on the spray roasting method of the present invention.

[0041] In this preferred embodiment, a stainless steel waste liquid regeneration system based on the spray roasting method includes an absorption tower 1, a spray washing tower 3, a spray cooling tower 5, an oxidation tower 7, and a denitrification device 32 connected in sequence, wherein,

[0042] The spray liquid outlet of spray scrubber 3 communicates with its first spray liquid inlet and the spray liquid inlet of absorption tower 1 through pipeline, and the spray liquid outlet of spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com