Online inspection and cleaning device of batteries

A cleaning device and battery technology, applied in the direction of cleaning methods using tools, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve the problems of affecting battery production efficiency, difficulty in on-site management, waste of battery handling, etc., to achieve Conducive to large-scale production, maximum efficiency, and balanced beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

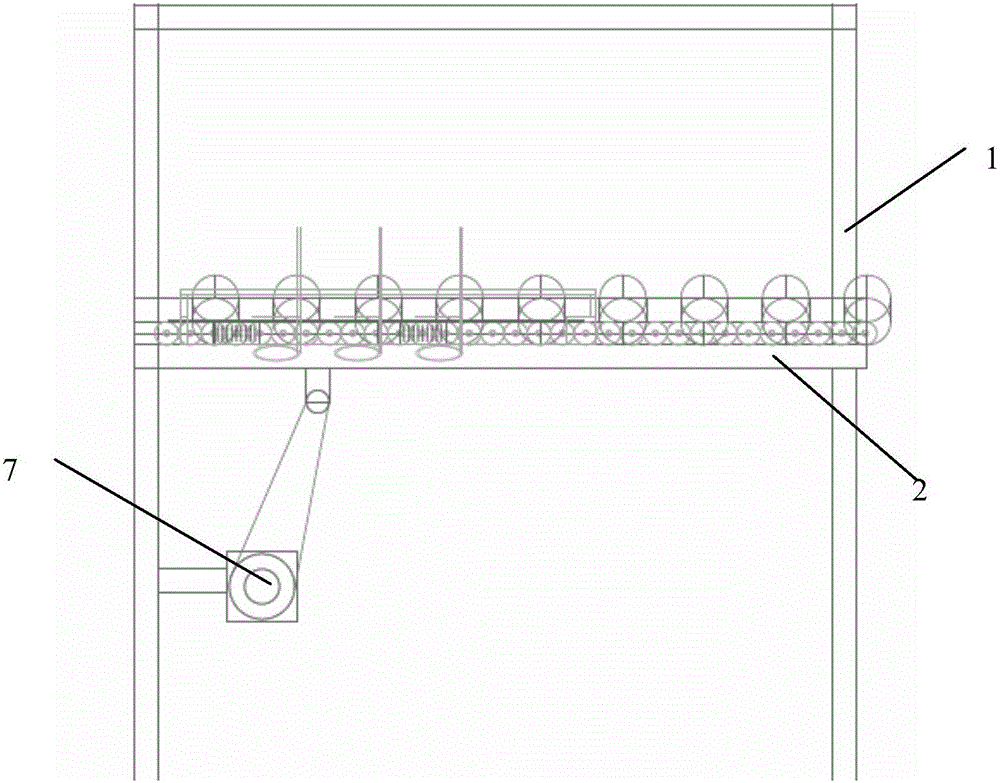

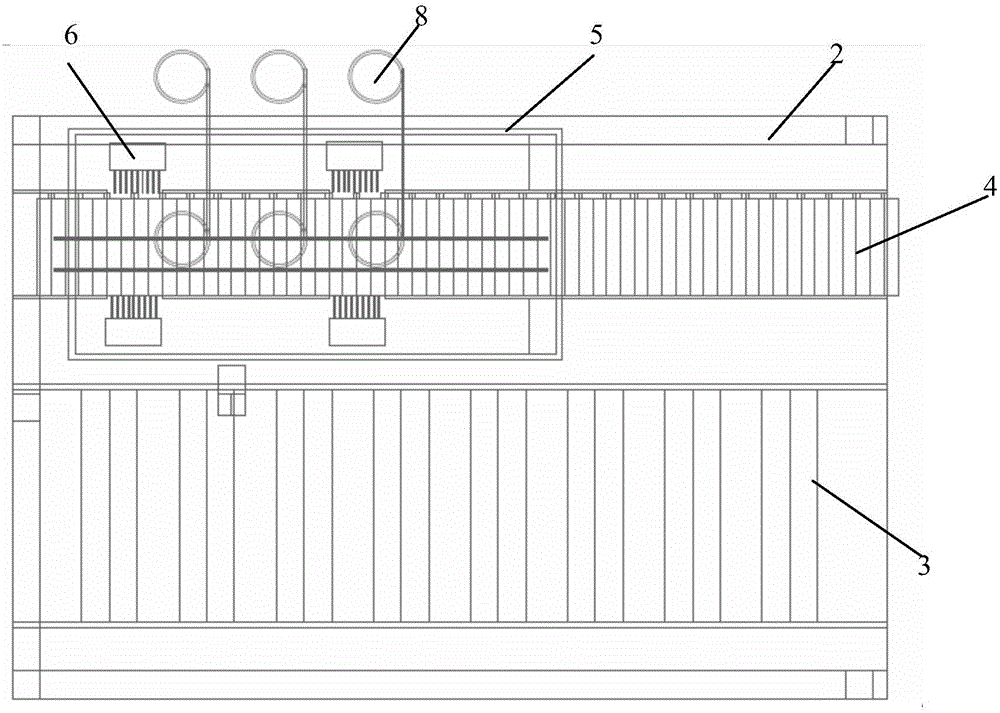

[0019] Such as figure 1 and 2 As shown, the on-line inspection and cleaning device for batteries of the present invention includes a frame 1 made of metal, a first transmission belt 3 arranged on the frame operating table 2 to carry the battery to be inspected, and arranged in parallel to the front and back at intervals or parallel to the top and bottom, and to carry the battery to be tested. The second conveyor belt 4 carrying the batteries that have passed the inspection, and the isolation cover 5 made of a transparent material that is arranged at the front and back of the end of the second conveyor belt and correspondingly forms an inlet and outlet, are respectively inside the iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com