Automatic processing device for on-line hook face groove of furnace shell of super-huge type blast furnace

A blast furnace shell and processing device technology, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to adapt to the construction environment, high requirements for cutting nozzles, and increased cutting costs, so as to shorten the rapid overhaul time of blast furnaces , high promotion and application value, and the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

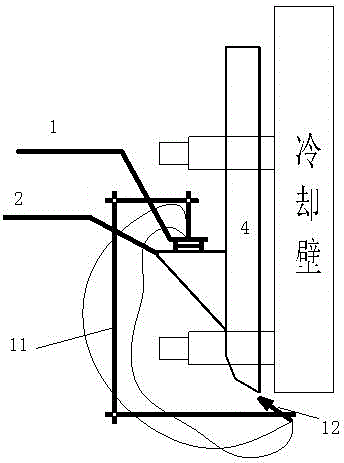

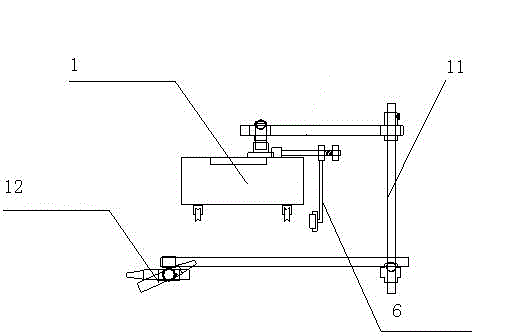

[0013] Such as Figure 1 to Figure 4 As shown, a super-large blast furnace shell on-line curved surface groove automatic processing device includes an automatic cutting device 1, and a matching annular guide rail 2 is provided near the ring seam of the large blast furnace shell 4, and the automatic cutting device Placed on it, the automatic cutting equipment can be moved along the guide rail and connected to the guide rail through the guide wheel mechanism. The positioning guide mechanism includes a guide wheel cross arm 3 connected to the top of the automatic cutting equipment, and the guide wheel cross arm is connected by a cross sleeve 5 The vertical guide wheel adjustment arm 6, the end of the guide wheel cross arm is covered with a spring 7 and a nut 9, one end of the spring is on the guide wheel adjustment arm, and a guide wheel 10 is provided under the guide wheel adjustment arm, and the guide wheel is stuck on the guide rail Above; the cutting arm 11 extending around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com