Method for washing aluminum alloy oxidation film to be welded via laser

A laser cleaning and oxide film technology, applied in cleaning methods and utensils, chemical instruments and methods, laser welding equipment, etc., can solve the problems of polluted environment, many processes, surface scratches and damage, achieve a high degree of automation, improve cleaning The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

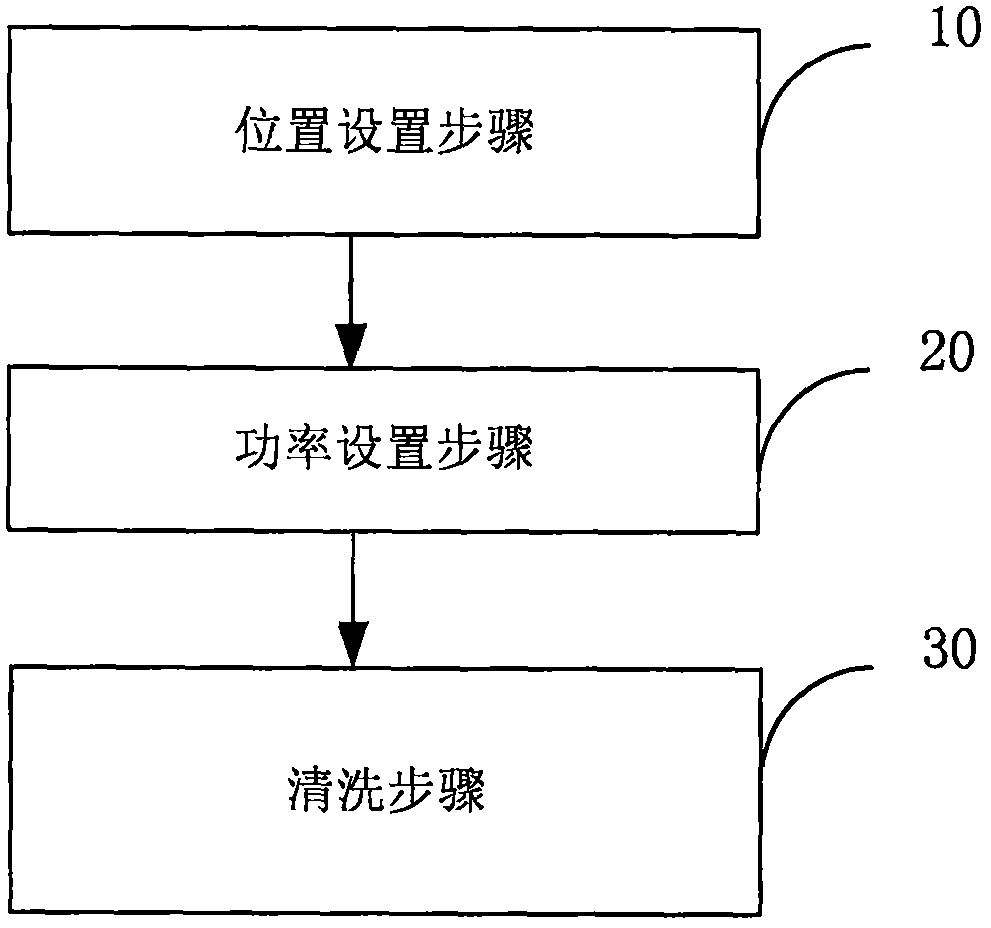

[0052] figure 1 is a flow chart of the steps of a method embodiment of the present invention, figure 2 is a schematic diagram of laser cleaning, such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a method for laser cleaning aluminum oxide film before welding, including:

[0053]Position setting step 10: setting the positions of the aluminum alloy workpiece and the laser oscillating lens, the laser oscillating lens can emit a laser beam 101 of short nanosecond pulses, the optical axis of the laser beam 101 is in contact with the aluminum alloy workpiece to be cleaned The surfaces 102 intersect and form an angle α at the intersection point, 30°≤α≤60°; set the compressed air nozzle 103 to point to the intersection point, and make the compressed air nozzle 103 form an angle β with the surface to be cleaned 102 , 10°≤β≤20°; set the suction nozzle 104 of the vacuum system to point to the intersection point, and make the suction nozzle 104 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com