Bread improver

A bread improver and amylase technology, which is applied in the field of bread food additives and bread improvers, can solve the problems of affecting the taste of consumers, shortening the shelf life of bread, and disappearing of bread aroma, so as to shorten the mixing time of materials and improve production Effect, mouthfeel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0022] The following table 1 is the composition of the bread improver, wherein specific examples 1-6 are set according to the formula described in the application; comparative examples 1-2 are based on the formula described in the application, and the ingredients that play a major role therein are changed Do formulation design. Wherein the pregelatinized waxy cornstarch A used in the specific examples is the coarse pregelatinized waxy cornstarch A described in the application, and its particle size satisfies the retention after sieving with a 220 μm sieve ≤ 40%; comparative implementation The pregelatinized waxy cornstarch B used in the example is ordinary pregelatinized waxy cornstarch, and its particle size meets the retention after sieving with a 75 μm sieve ≤ 35%, and the retention after sieving with a 150 μm sieve is ≤ 2%; The gluten A used in the specific embodiment is the gluten described in the application, and its moisture content is 6.5-6.6%, and wet basis protein co...

Embodiment approach 2

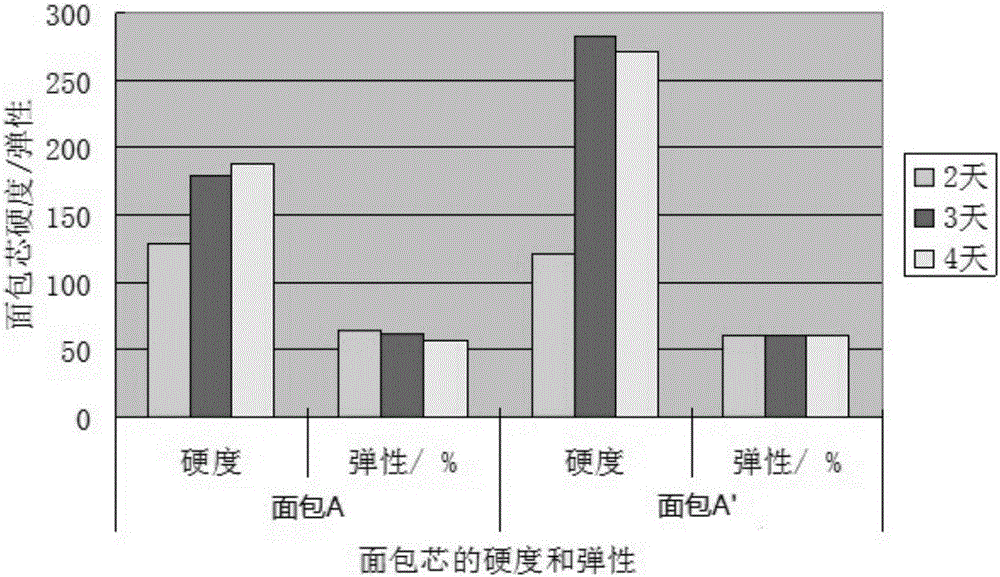

[0033] The above-mentioned bread A and A' prepared when using the bread improver of specific example 1 and comparative example 1 were stored in cold storage, and then the bread cores at different storage days were analyzed for texture. The obtained results can be found in figure 1 shown. Depend on figure 1 It can be seen that in the first four days of refrigerated storage, the bread core elasticity of bread A and bread A' are similar; in the first two days of refrigerated storage, the bread core hardness of bread A and bread A' is the same, but on the third day and On the fourth day, the hardness of the bread core of bread A was lower than the hardness of the bread core of bread A'. The above results show that using the gluten used in the present application as a component of the bread improver can effectively improve the anti-aging performance of bread, and its anti-aging performance is obviously better than the situation when gluten is the most common component of the bread...

Embodiment approach 3

[0035]When preparing the bread improver shown in the formula of specific example 3 and comparative example 2 in the above table 1, the raw materials α-amylase, xylanase, maltose amylase, diacetyl tartaric acid monoglyceride, monoglyceride (Double) glycerol fatty acid esters, sodium stearoyl lactylate, xanthan gum, sodium carboxymethylcellulose, vitamin C and all of the pregelatinized waxy cornstarch are mixed evenly to form a mixture, and then the mixture is added to the standing Mix the rest of the pre-gelatinized waxy corn starch and all the gluten in the mixer for 20 minutes at a speed of 12 r / min, and then take samples from the four corners and the center of the mixer to obtain samples of the bread improver. Then the bread improver samples are added to the flour according to the mass ratio of 1.5 bread improver: 100 flour and mixed evenly, then the mixed bread is placed on the flour board, pressed to form a smooth slope, the flour board Immerse the pressed panel block in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com