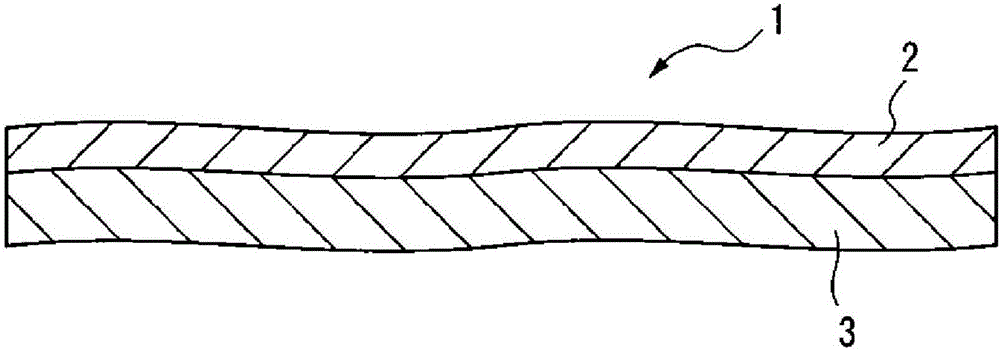

Noise-absorbing sheet

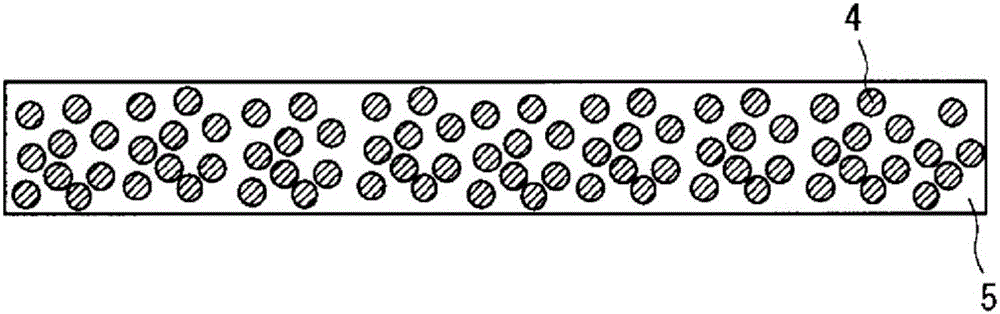

A noise-absorbing, fabric-based technology, applied in the field of noise-absorbing sheets, can solve the problems of superimposed noise-absorbing performance, expensive materials, and low noise-absorbing performance, and achieve excellent noise-absorbing performance, excellent flexibility, and high noise-absorbing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

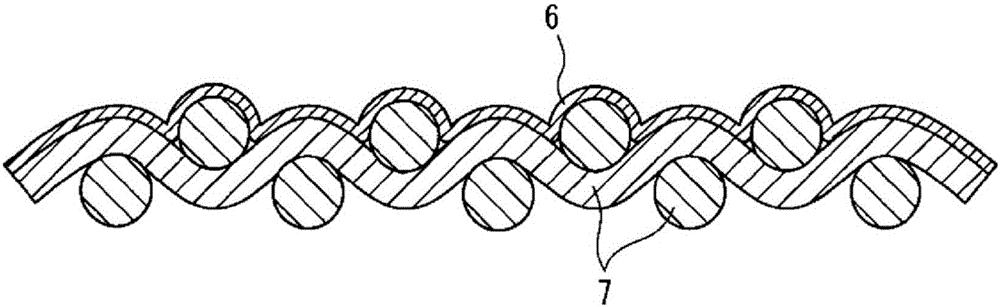

[0186] A spun-bonded non-woven fabric made of polyester resin (product name: Pureshize, product number: AS030) produced by Asahi Kasei Fiber Co., Ltd. manufactured by the production method shown below was used as the fabric, and metal processing was performed, and a commercially available magnetic sheet was used. Paste, and measure the noise absorption performance.

[0187] For general-purpose polyethylene terephthalate, the long fiber group of the filament is extruded to the moving collection surface at a spinning temperature of 300°C by the spunbonding method, and the spinning is carried out at a spinning speed of 3500m / min. Corona electrification makes it charge about 3μC / g to fully open the fiber, and the basis weight on the collecting mesh surface is about 7.5g / m 2 An unbonded long-fiber sheet (hereinafter sometimes referred to as "sheet layer A") formed of filaments having an average fiber diameter of 11 μm and having a uniformity of 5 cm change rate of 15% or less was f...

Embodiment 2~24

[0198] Using the above-mentioned Example 1 as the basic condition, the configuration / properties of the noise absorbing fabric and the magnetic sheet were changed. The points of change are shown in Table 1 and Table 2 below.

[0199] In Example 2, as the commercially available magnetic sheet of Example 1, a magnetic sheet manufactured by Doosung Corporation was used.

[0200] In Example 3, as the commercially available magnetic sheet of Example 1, a magnetic sheet (thickness: 100 μm) manufactured by NEC-TOKIN was used.

[0201] In Example 4, as the commercially available magnetic sheet of Example 1, a magnetic sheet (thickness: 50 μm) manufactured by 3M was used.

[0202] In Example 5, the vapor deposition time was changed to change the thickness of the metal, and it followed Example 1 except that.

[0203] Example 6 follows Example 1 except that the metal is changed to Ag.

[0204] Example 7 Followed Example 1 except that the base material of the noise absorbing fabric was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com