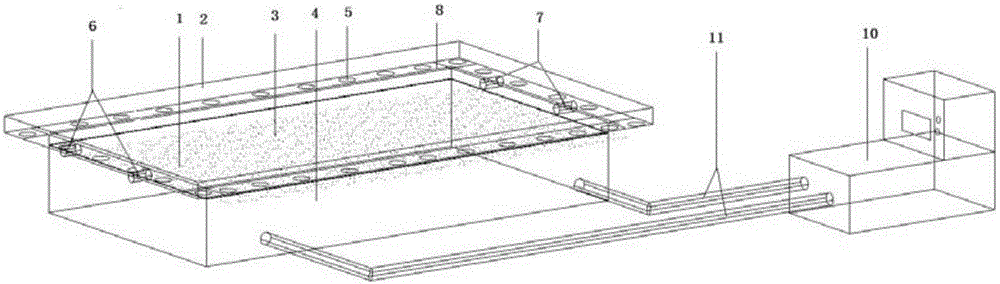

Temperature-controlled reusable two-dimensional visualization porous medium sand packed model and method of manufacture

A porous medium and model technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of high production cost, inability to visualize, difficult to clean models, etc., achieve good light transmission and visibility, and facilitate collection and processing , Easy to clean and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

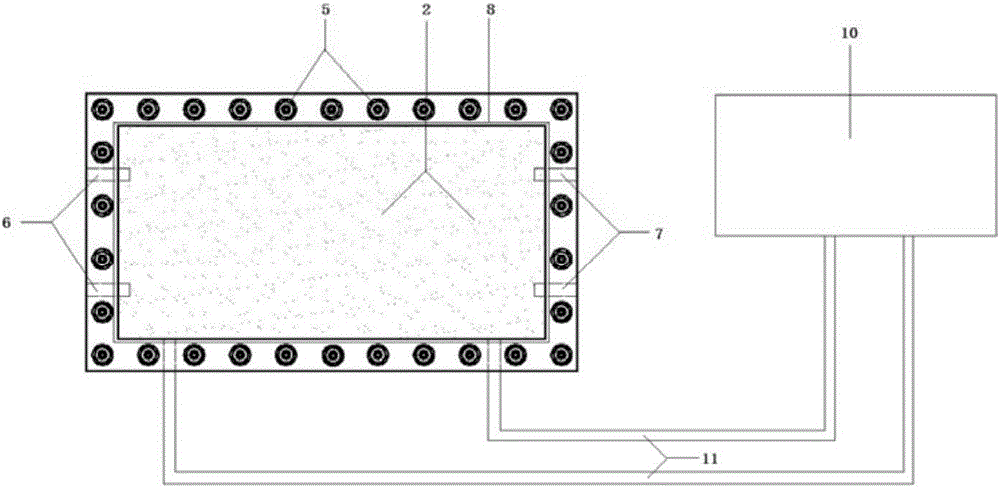

Method used

Image

Examples

Embodiment 1

[0048] In the temperature-controllable and reusable two-dimensional visual porous media sand filling model of this embodiment, the filling cavity 3 is filled with pure and refined quartz sand of 70-100 mesh, 120-140 mesh, and 180-200 mesh respectively; high permeability can be simulated respectively , medium permeability, and low permeability reservoir conditions.

Embodiment 2

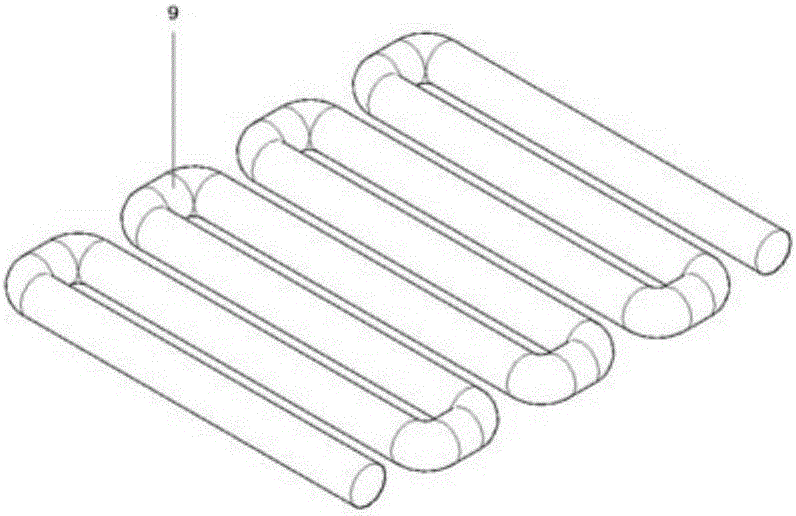

[0050] In the temperature-controllable and reusable two-dimensional visual porous media sand filling model of this embodiment, the injection port 6 of the entire model is upwards, the two production ports 7 are closed, and it is erected. The inner sides of the two injection ports 6 can be connected with a stainless steel round pipe Connect to form a simulated wellbore; the simulated wellbore is made of capillary steel pipe and plastic pipe, the side of the capillary is perforated, the plastic pipe is packed with dense irregular micropores, and the capillary is filled with quartz sand to simulate the sand control process of gravel filling.

[0051] The beneficial effects of the present invention are:

[0052] (1) The main body is made of stainless steel with high mechanical strength and high temperature resistance, which avoids damage to the model due to high temperature and provides conditions for high temperature resistance;

[0053] (2) The main body and the cover plate are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com