Electric control dimming glass

A dimming glass and electric control technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as damage and ion conductor layer impact, and achieve stable antistatic performance, high self-cleaning performance, and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

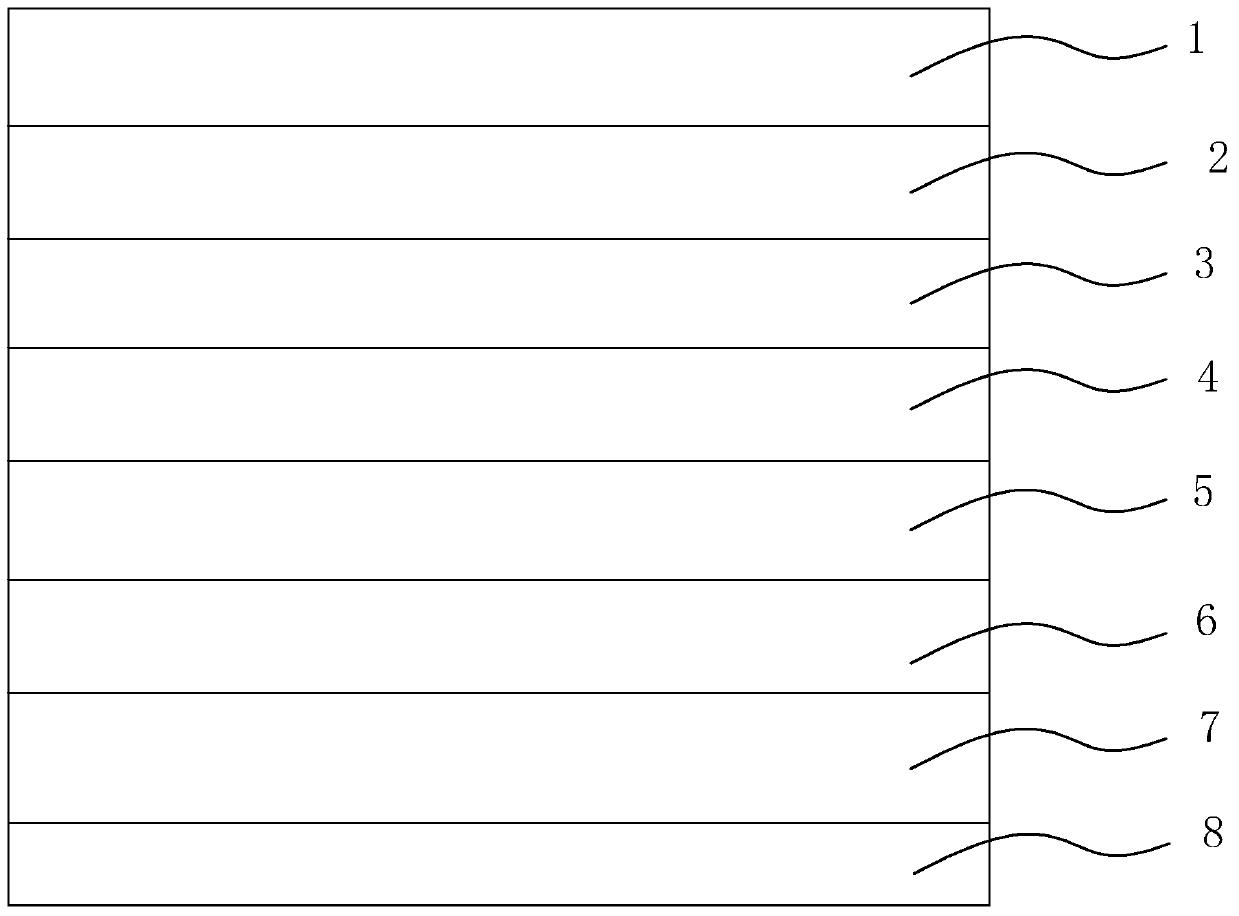

[0024] Embodiment 1. Participation figure 1 As shown, an electronically controlled dimming glass includes a first transparent glass substrate layer 1, a first transparent conductive layer 2, an ion storage layer 3, an ion conductor layer 4, an electrochromic layer 5, a second The transparent conductive layer 6, the second transparent glass substrate layer 7 and the protective layer 8 are connected by a transparent adhesive between the second transparent glass substrate layer 7 and the protective layer 8, and the transparent adhesive includes 5 wt% of methyl Acrylates; 3wt% liquid polybutadiene; 0.5wt% benzophenone; 0.5wt% organic peroxide, 8wt% bis(2-ethylhexyl) phthalate; 5wt% Nano antistatic base material; wherein the nano antistatic base material is composed of acrylic resin, antimony-doped tin dioxide nano powder, isopropanol, methyl ethyl ketone and diphenyl Base dimethoxysilane composition, wherein the doping molar ratio Sb:Sn = 9:50 in antimony-doped tin dioxide nanopo...

Embodiment 2

[0029] Embodiment 2, an electronically controlled dimming glass, comprising a first transparent glass substrate layer 1, a first transparent conductive layer 2, an ion storage layer 3, an ion conductor layer 4, an electrochromic layer 5, a first Two transparent conductive layers 6, a second transparent glass substrate layer 7 and a protective layer 8, are connected by a transparent adhesive between the second transparent glass substrate layer 7 and the protective layer 8, and the transparent adhesive includes 35 wt% formazan 28wt% liquid polybutadiene; 3wt% ultraviolet photoinitiator, wherein the ultraviolet photoinitiator is the composition of diethoxyacetophenone, benzoin methyl ether; 3wt% hydrogen-containing Peroxide, 35wt% bis (2-ethylhexyl) phthalate; 7wt% nanometer antistatic base material; wherein the nanometer antistatic base material is 50:25:10:12 by weight: 3 acrylic resin, antimony-doped tin dioxide nanopowder, isopropanol, butanone and diphenyldimethoxysilane, wh...

Embodiment 3

[0034] Embodiment 3, an electronically controlled dimming glass, including a first transparent glass substrate layer 1, a first transparent conductive layer 2, an ion storage layer 3, an ion conductor layer 4, an electrochromic layer 5, and a second Two transparent conductive layers 6, a second transparent glass substrate layer 7 and a protective layer 8, are connected by a transparent adhesive between the second transparent glass substrate layer 7 and the protective layer 8, and the transparent adhesive includes 55 wt% formazan 50 wt% liquid polybutadiene; 5 wt% benzoin methyl ether; 5 wt% diacyl peroxide, 65 wt% dibutyl phthalate; 15 wt% nano Antistatic base material; wherein the nano antistatic base material is composed of acrylic resin, antimony-doped tin dioxide nano powder, isopropanol, methyl ethyl ketone and diphenyl Dimethoxysilane composition, wherein the doping molar ratio Sb:Sn=9:50 in antimony-doped tin dioxide nanopowder.

[0035]In this embodiment, the protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com