Cross-linked polyethylene cable detecting device

A cross-linked polyethylene and detection device technology, applied in the direction of fault location, testing dielectric strength, etc., can solve problems such as insulation faults, complexity of operating environment, structural defects of cable accessories, etc., and achieve the effect of overcoming low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

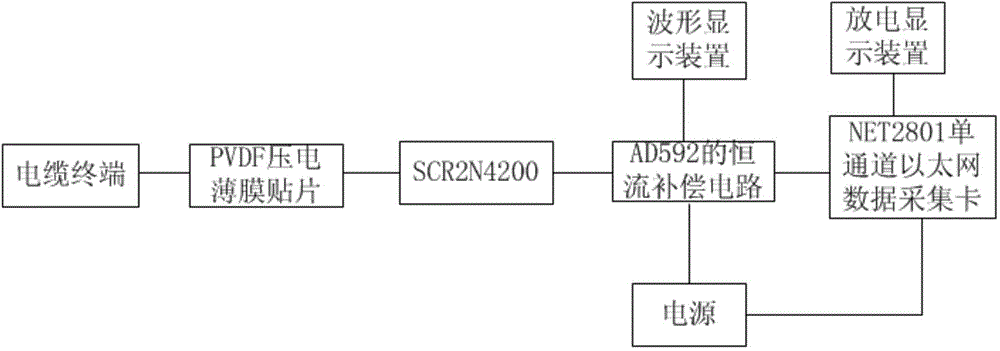

[0009] like figure 1 As shown, the cross-linked polyethylene cable detection device includes an acoustic emission sensor, a gating circuit, a trigger signal conditioning circuit, an analog signal processing circuit, a data acquisition card and a host computer, the acoustic emission sensor is located at the cable terminal, and the acoustic emission The sensor, the gate circuit, the trigger signal conditioning circuit, the analog signal processing circuit, the data acquisition card and the host computer are connected in sequence, the acoustic emission sensor is a PVDF piezoelectric film patch, the gate circuit is SCR2N4200, and the trigger signal The conditioning circuit is a constant current compensation circuit of AD592, and the data acquisition card is a NET2801 single-channel Ethernet data acquisition card.

[0010] It also includes a power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com