Reconfigurable quarter-mode substrate integrated waveguide microwave microfluidic sensor

An integrated waveguide and microfluidic technology, applied in the microwave field, can solve the problems of low sensitivity, low experiment, error, etc., and achieve the effect of overcoming low sensitivity, high sensitivity and Q value, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with specific embodiments in conjunction with the accompanying drawings.

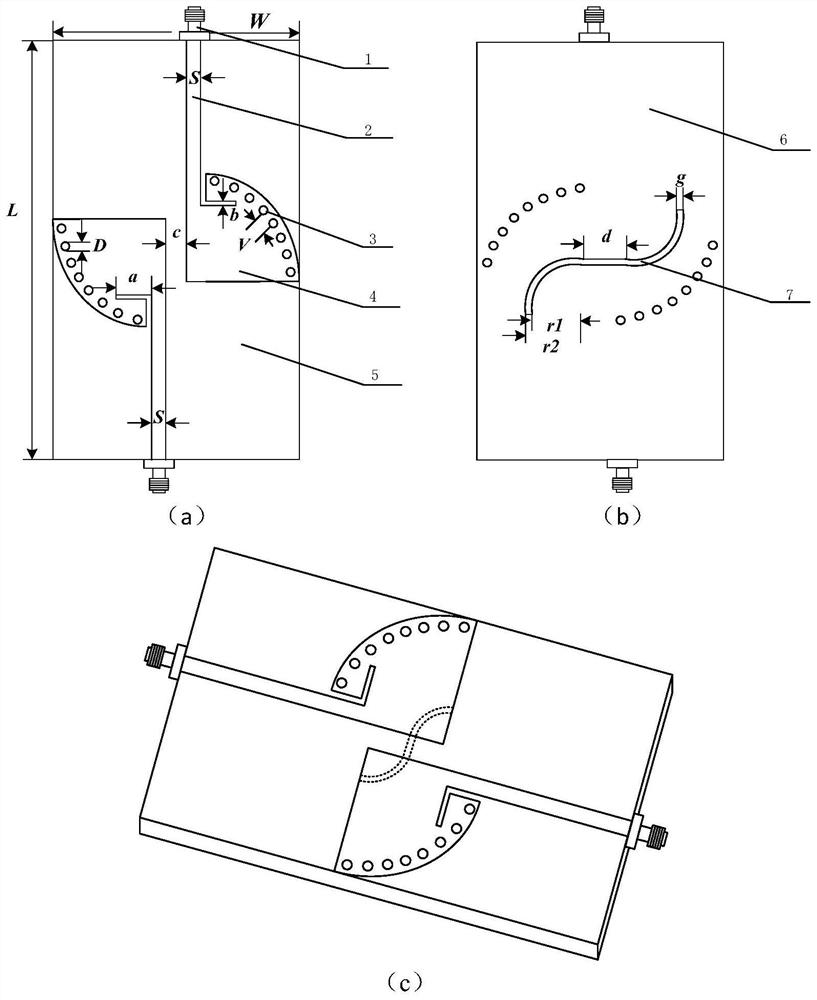

[0034] like figure 1 Shown is a schematic structural diagram of the present invention. The sensor of the present invention is a two-port device, which specifically includes the following:

[0035] The top layer includes two units with the same structure, each unit includes a metal patch 4, a microstrip line 2 and an SMA connector 1;

[0036] The middle layer is Rogers 4350 dielectric board 5;

[0037] The bottom layer includes a metal sheet 6 and a grooved CSRR structure 7;

[0038] The metal patch is provided with a number of metal through holes 3 arranged at equal distances (preferably at a distance of 10°) along the fan-shaped arc edge, for coupling the bottom metal sheet;

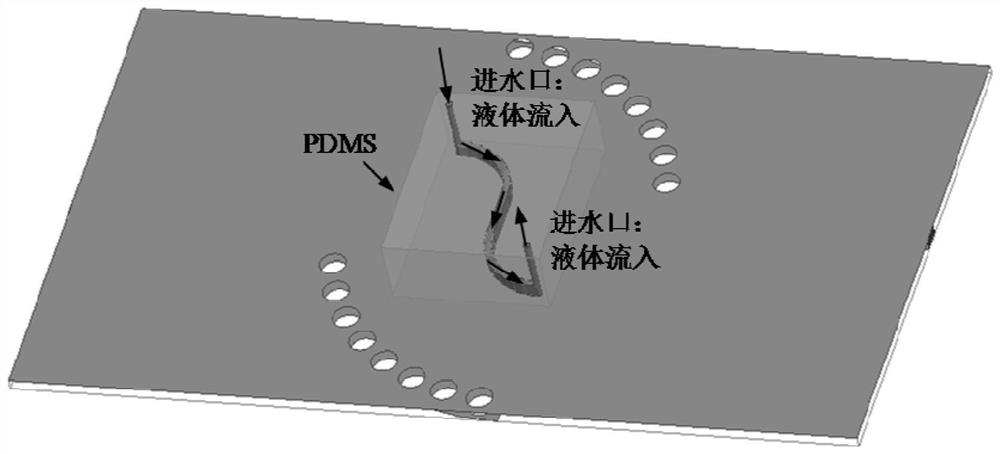

[0039] When in use, turn the sensor upside down, place PDMS with microfluidic channel dug inside on CSRR groove ring 7, inject 10% concentration at 10% con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com