Two-stage rotary blade type vacuum pump

A technology for rotary vane vacuum pumps and pump chambers, which is applied to rotary piston pumps, rotary piston/swing piston pump components, rotary piston machinery, etc., and can solve the problems of reducing the quality of the working environment, high noise of vacuum pumps, and extreme pressure. Small and other problems, to achieve a wide range of use, increase the limit pressure, prolong the life of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

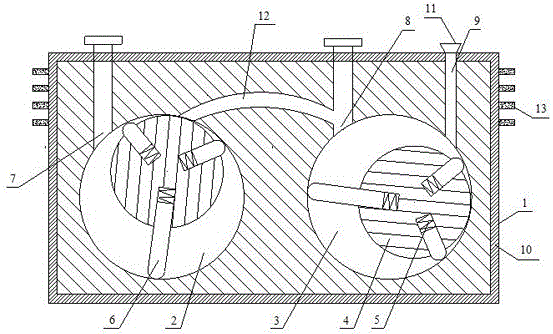

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0013] Such as figure 1 As shown, a two-stage rotary vane vacuum pump includes a pump body 1, a first pump chamber 3 and a second pump chamber 2 are arranged in the pump body 1, and an inlet communicating with the first pump chamber 3 is provided on the pump body 1. The air pipe 9, the first exhaust port 8 of the first pump chamber 3 communicate with the second pump chamber 2 through the serial passage 12, the second pump chamber 2 is provided with a second exhaust port 7, the first pump chamber 3 and the second pump chamber In the two pump chambers 2, there are rotor 4, three rotating vanes 6 and vane springs 5 evenly distributed on the central plane of the rotor. Cut, the rotary vane 6 is provided with a rotary vane spring 5, and the rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com