Efficient automobile accessory grinding device

A high-efficiency technology for auto parts, applied in the direction of grinding/polishing safety devices, grinding machines, grinding machine parts, etc., can solve the problems of easily damaged auto parts, low grinding quality, waste of working time, etc., and achieve good grinding effect. , Economical and practical, high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

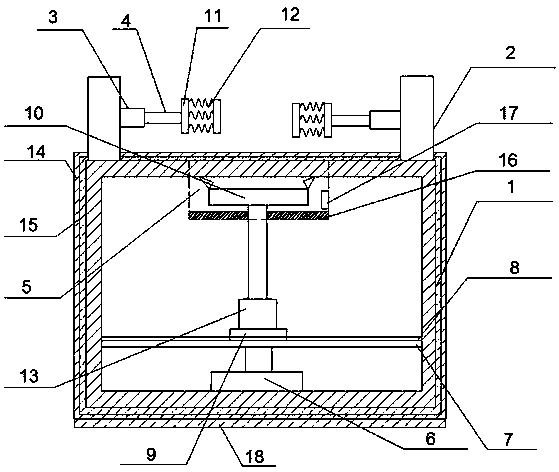

[0014] Such as figure 1 As shown, a kind of high-efficiency auto parts grinding device includes a housing 1, the surface of the housing is provided with a sound-insulating layer, and the sound-insulating layer includes a noise-absorbing coating 14 and a porous noise-absorbing layer 15 on the outer surface. The top of the body 1 is provided with two first fixed columns 2, and the two first fixed columns 2 are respectively located on both sides of the housing 1, and the sides of the first fixed columns 2 close to each other are provided with sliding grooves, and the sliding grooves A sliding post 3 is slidably connected to the inner wall of the groove, and an electrohydraulic rod 4 is connected to the sliding post 3. A clamping device is provided at the end of the electrohydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com