Combined Mechanical Injection-Boost Piezojet Mixed Fuel Injection Device

A technology of fuel injection device and mechanical fuel injection, applied in the direction of fuel injection device, special fuel injection device, oil supply device, etc., can solve the problem of long transmission pipeline, reduction of gas injection pressure and injection rate, affecting engine power and fuel economy The effect of high gas boost pressure and gas boost efficiency, increasing gas injection pressure and injection rate, and meeting the requirements of system injection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in more detail below in conjunction with accompanying drawing example:

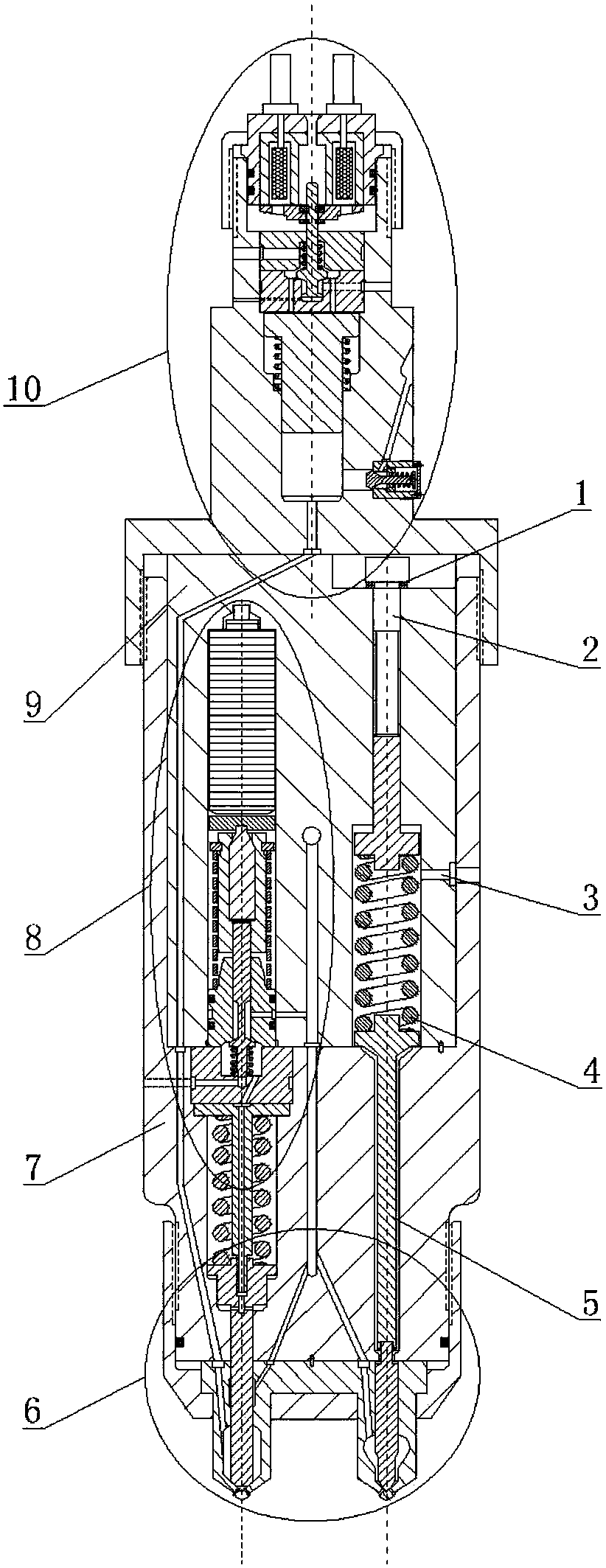

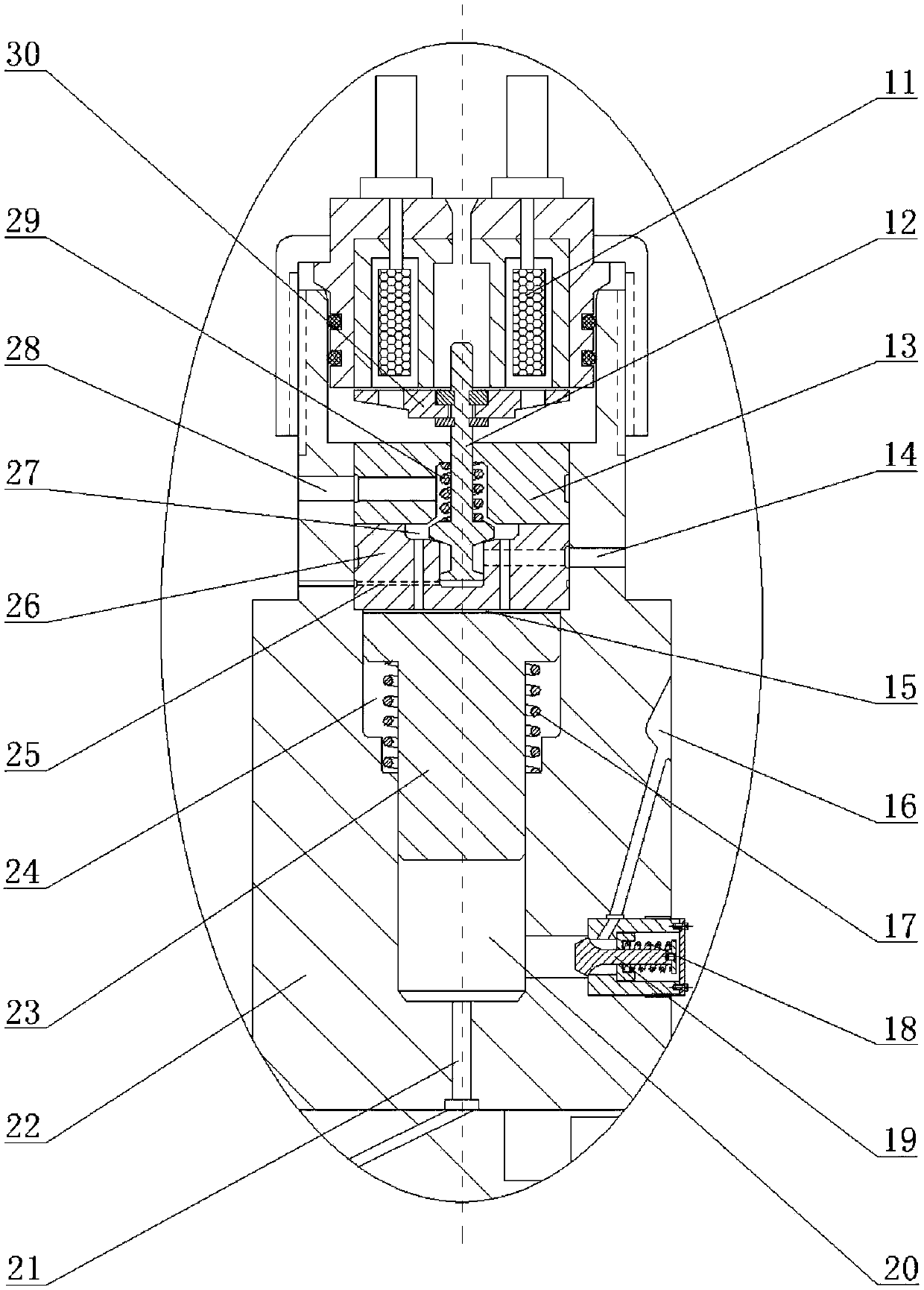

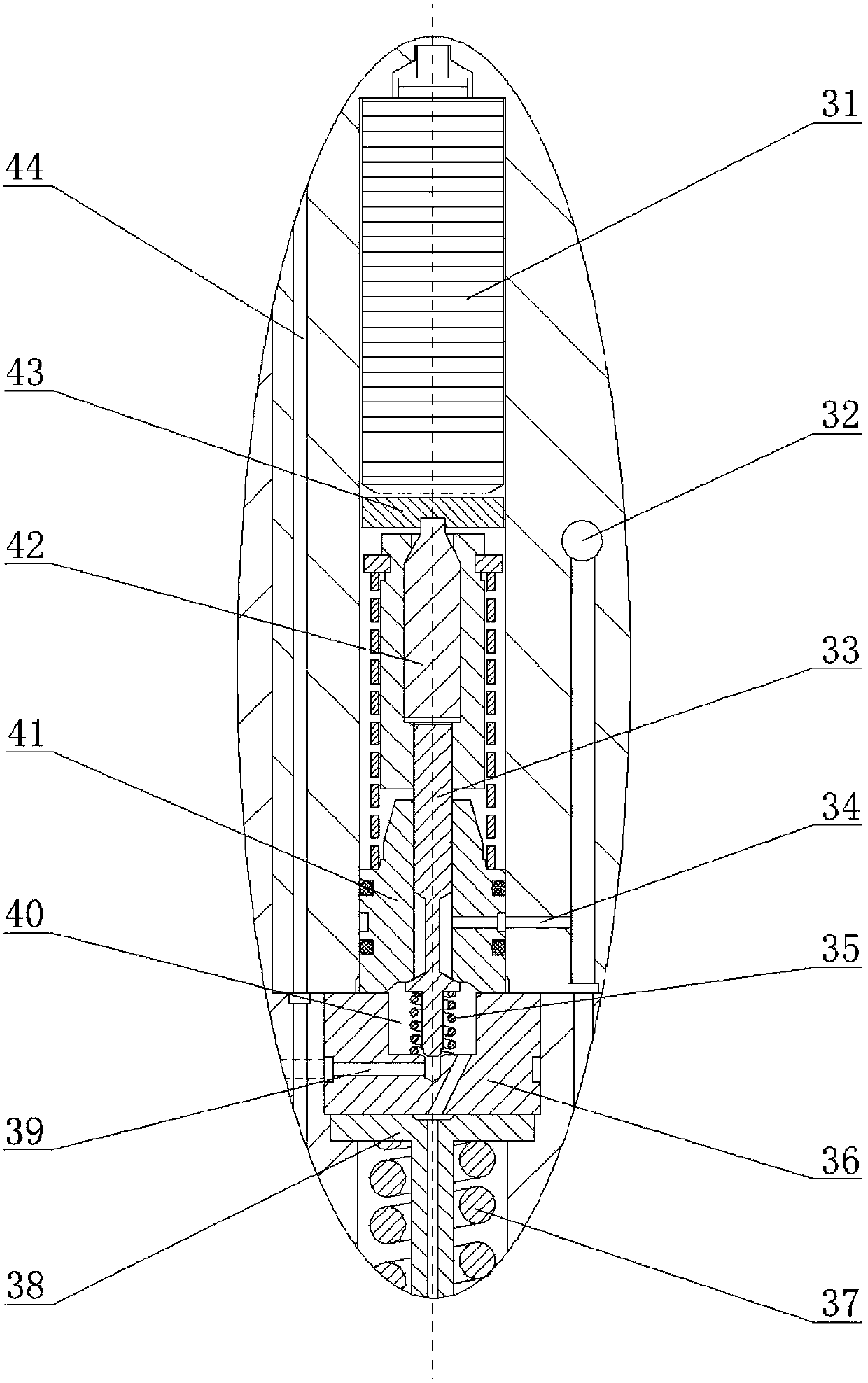

[0021] combine Figure 1~4, the combined mechanical fuel injection-supercharged piezoelectric jet mixed fuel injection device of the present invention mainly includes a gas booster part 10, a piezoelectric control part 8, a nozzle part 6, a supercharging device housing 22, a control device housing 9, an injection device Shell 7, air intake channel 44, oil inlet oil channel 32, pressure regulating screw 2, washer 1. The gas booster part 10 is composed of an air inlet 16, a booster gas outlet 21, a booster oil inlet 14, a booster oil drain port 28, a booster piston 23, a booster piston upper cavity 15, a booster piston lower cavity 20. Booster piston reset spring 17, booster piston reset spring cavity 24, booster solenoid valve coil 11, booster armature 30, booster control valve 12, booster control valve reset spring 29, booster control valve oil cavity 27 , super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com