Energy-saving high-pressure homogenizing device for producing powdered oil

A high-pressure homogenization, powdered grease technology, applied in transportation and packaging, mixers, mixing methods, etc., can solve the problems of short life, unable to guarantee continuous production, slow pressurization efficiency, etc., to improve the service life and solve the problem of metal particles The effect of residual fall and high boosting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

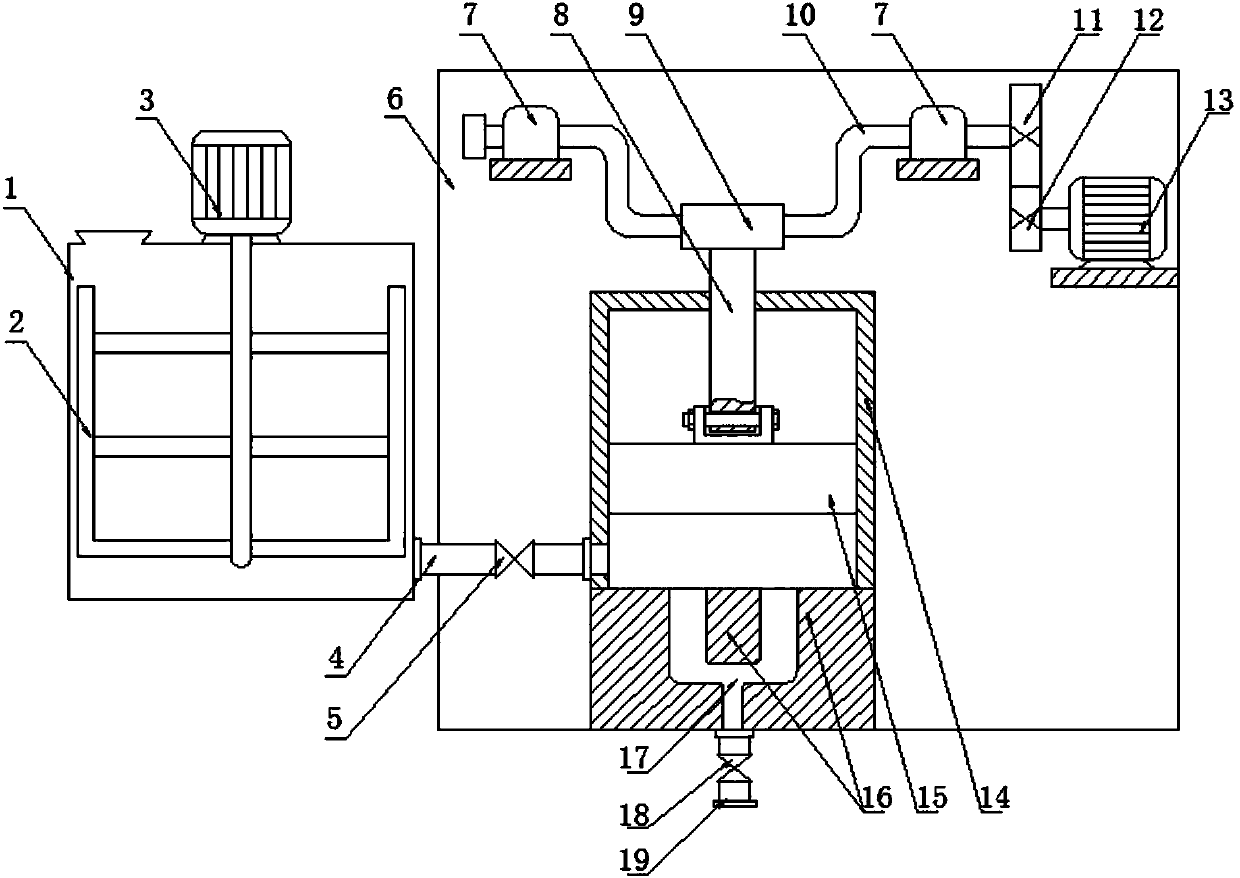

[0009] Embodiment 1, as figure 1 As shown, an energy-saving high-pressure homogenization device for producing powdered oil, including an emulsification tank 1, a U-shaped stirring paddle 2, a first motor 3, a first discharge pipe 4, a first one-way valve 5, and a body 6 , supporting bearing 7, connecting rod 8, bushing 9, crankshaft 10, driven gear 11, driving gear 12, second motor 13, booster cylinder 14, piston 15, homogenizing block 16, homogenizing chamber 17, second One-way valve 18, second discharge pipe 19; wherein: the first motor 3 is installed on the top of the emulsification tank 1, the first motor 3 is coaxially connected with the U-shaped stirring paddle 2, and the bottom of the emulsification tank 1 is connected with the first discharge pipe 4. The first discharge pipe 4 is provided with a first one-way valve 5, the first discharge pipe 4 is connected to the first discharge pipe 4 through the machine body 6, and the emulsification tank 1 is connected to the boost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com