Water-thinned epoxy wood white primer and preparation method thereof

An epoxy woodware, water-dilutable technology, applied in the field of paint, can solve the problems of poor physical and chemical properties of the coating film, unstable coating film quality, poor yellowing resistance of PU white primer, etc., and achieve improved yellowing resistance , Excellent color fastness, excellent light stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

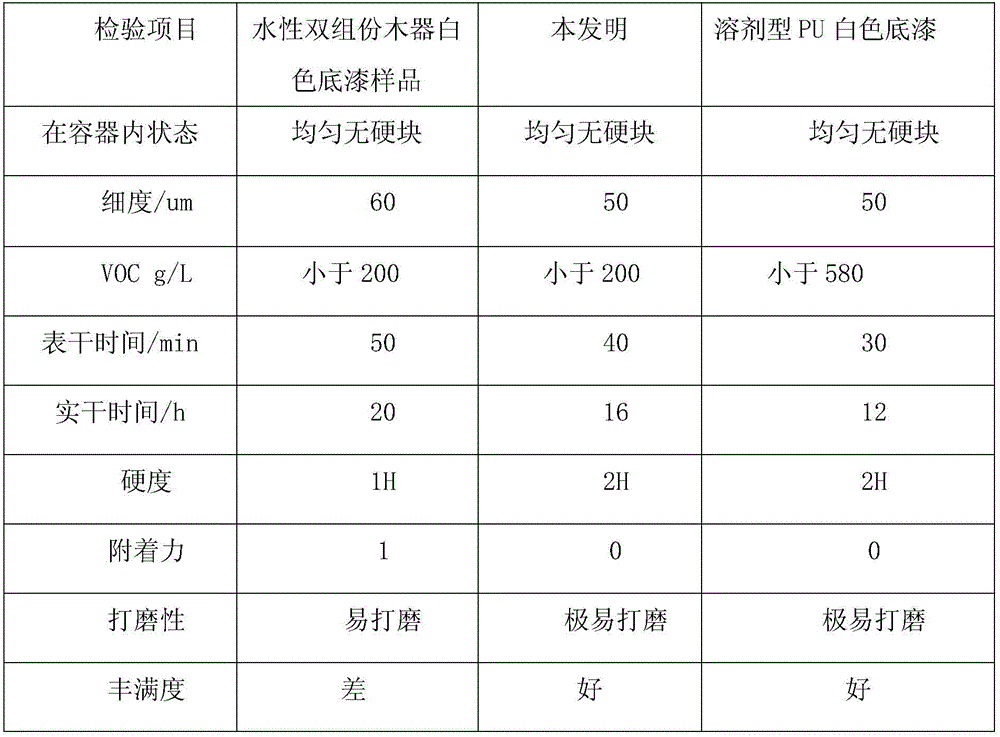

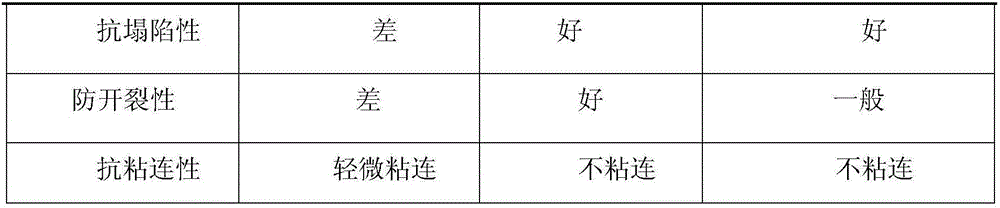

Examples

Embodiment 1

[0027] Prepare the main paint: weigh 100kg in total according to the following mass percentages: 52kg of bisphenol A epoxy resin E44, 0.3kg of polyether modified polysiloxane defoamer, and high molecular weight block containing pigment affinity groups Copolymer dispersant 0.6kg, polyether modified polydimethylsiloxane leveling agent 0.4kg, organic bentonite 1kg, rutile titanium dioxide 18kg, zinc stearate and talcum powder mixed filler 12kg, propylene glycol methyl ether 7.7 kg, ethanol 8kg; after weighing the raw materials according to the above mass components, first fully mix the dispersant at room temperature to avoid the effect of stratification and turbidity during storage and transportation; then bisphenol A epoxy Resin E44 and half of the mass of propylene glycol methyl ether and ethanol were put into a container and stirred evenly, and then polyether modified polysiloxane defoamer, high molecular weight block copolymer dispersant containing pigment affinity groups, Or...

Embodiment 2

[0031]Prepare the main paint; weigh 100kg according to the following mass components: bisphenol A type epoxy resin E44 weighs 46kg, polyether modified polysiloxane defoamer 0.2kg, high molecular weight embedding agent containing pigment affinity group Segment copolymer dispersant 0.5kg, polyether modified polydimethylsiloxane leveling agent 0.3kg, organic bentonite 1.5kg, rutile titanium dioxide 15.5kg, zinc stearate and talcum powder mixed filler 16kg, propylene glycol 11kg of methyl ether, 9kg of ethanol; after weighing the raw materials according to the above mass components, first fully mix the dispersant at room temperature to avoid the effect of stratification and turbidity during storage and transportation; then bisphenol A type Epoxy resin E44 and half of the mass of propylene glycol methyl ether and ethanol were put into a container and stirred evenly, and then polyether modified polysiloxane defoamer and high molecular weight block copolymer containing pigment affinit...

Embodiment 3

[0035] Prepare the main paint: weigh 100kg in total according to the following mass percentages: prepare the main paint: weigh 100 kg in total according to the following mass percentages: weigh 42 kg of bisphenol A epoxy resin E44, polyether modified polysiloxane defoamer 0.3 kg, 0.5kg of high molecular weight block copolymer dispersant containing pigment affinity groups, 0.4kg of polyether modified polydimethylsiloxane leveling agent, 2kg of organic bentonite, 15kg of rutile titanium dioxide, stearic acid Zinc and talcum powder mixed filler 20kg, propylene glycol methyl ether 9.8kg, ethanol 10kg; after weighing the raw materials according to the above mass components, first fully mix the dispersant at room temperature to avoid stratification and turbidity during storage and transportation Affect its effect; Next, put bisphenol A type epoxy resin E44 and half of the mass of propylene glycol methyl ether and ethanol into the container and stir and mix evenly, then add polyether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com