Low-filling high-heat-conductivity organic-inorganic compound

An inorganic composite and high thermal conductivity technology, applied in the field of organic-inorganic composites, can solve the problems of thermal conductivity impact, high thermal conductivity filler content affecting contact area and heat dissipation capacity, and product cost increase, so as to reduce interface thermal resistance and achieve remarkable technology The effect of progress and economic value, low cost of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

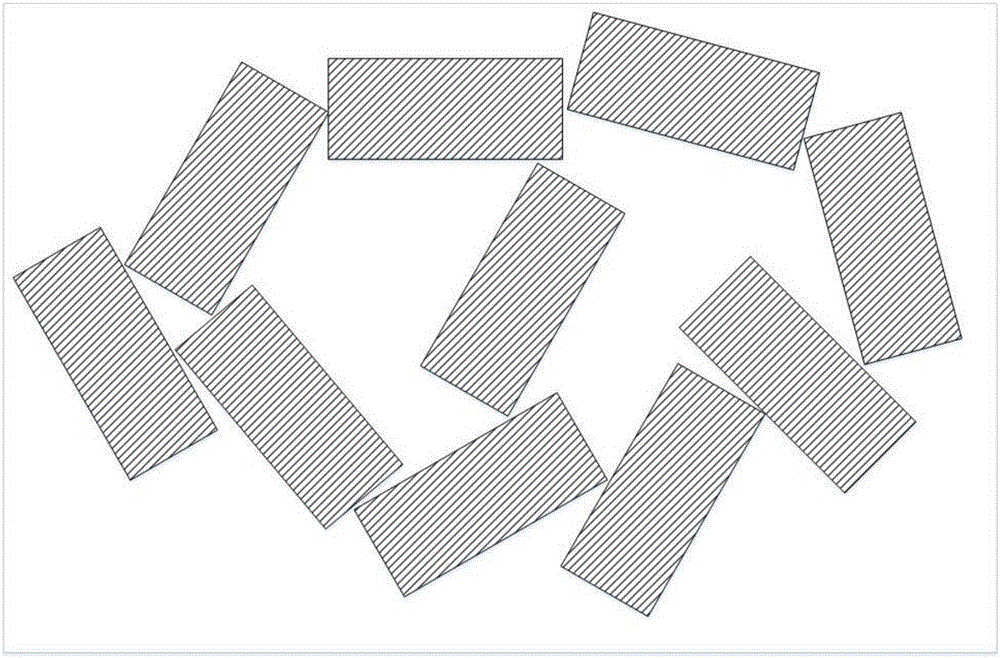

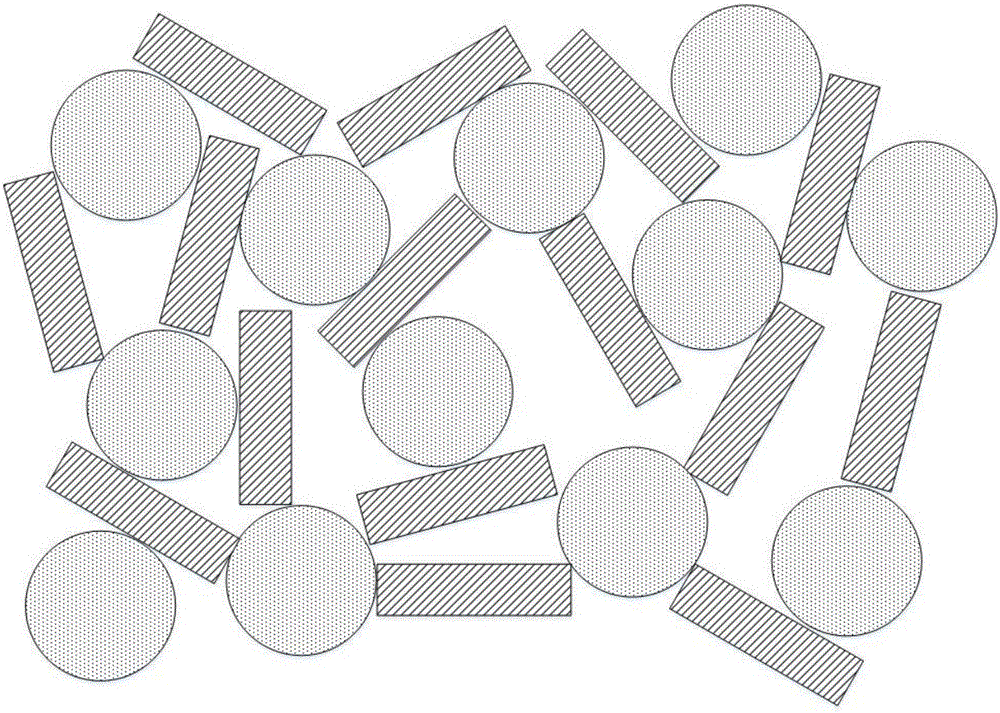

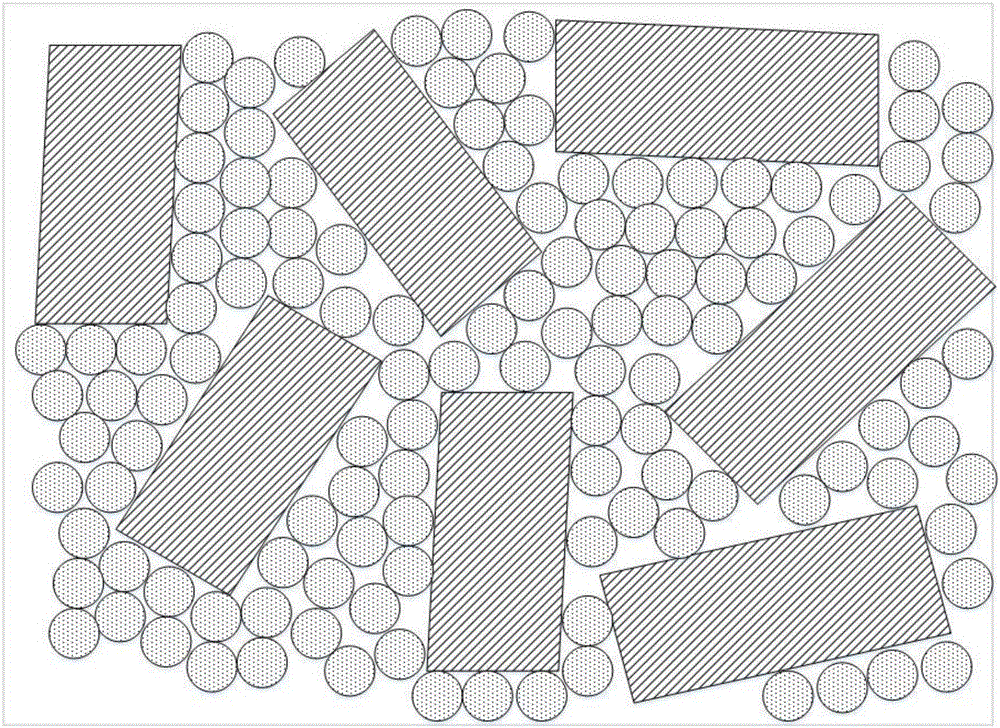

Method used

Image

Examples

Embodiment 1

[0036]Add 100 parts of spherical metal aluminum powder into the ball mill, add solvent oil, 6 parts of stearic acid and 7 parts of polyethylene wax at the same time, ball mill for 8 hours, use a sieving machine to screen out 200 mesh flake aluminum powder fillers, 90 °C for 12 hours in vacuum to obtain flake aluminum powder. Add 100 parts of flake aluminum powder and 700 parts of spherical alumina after ball milling into the high-speed mixer, stir for 0.5 hours, add 400 parts of vinyl silicone rubber, continue stirring for 2 hours, and put the product at 60 ° C The thermally conductive silicone grease with high thermal conductivity was prepared by vacuum drying. The thermal conductivity of the composite was measured to be 2.5K / w.M using a Setaram thermal conductivity meter TCI (the same below).

Embodiment 2

[0038] 200 parts of boron nitride were ball milled for 2 hours, dispersed in water, and ultrasonically stripped for 12 hours to prepare flake boron nitride. Add 200 parts of ultrasonicated boron nitride and 400 parts of zinc oxide into the high-speed mixing tank and stir for 1.5 hours. Continue to add 300 parts of vinyl silicone rubber, continue to stir for 2 hours, and vacuum dry the product at 80° C. for 12 hours to obtain thermally conductive silicone grease with high thermal conductivity. The thermal conductivity of the test compound is 2.0K / w.M.

Embodiment 3

[0040] Add 150 parts of graphite flakes, 100 parts of flaky boron nitride, and 400 parts of spherical aluminum powder into a high-speed mixing kettle and stir for 2 hours. After heating to remove excess solvent, add 400 parts of polyethylene glycol 400, continue to stir for 8 hours and dry to prepare a thermally conductive compound with high thermal conductivity. The thermal conductivity of the test compound was 3.8K / w.M.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com