Hollow single screw extruder with vibrating mandrel

A single-screw extruder and hollow screw technology, applied in the field of polymer material molding equipment, can solve the problems of dragging, homogenization, not particularly strong mixing, fast heat loss, low thermal efficiency, etc., to achieve internal quality and appearance Improved quality, simple structure, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

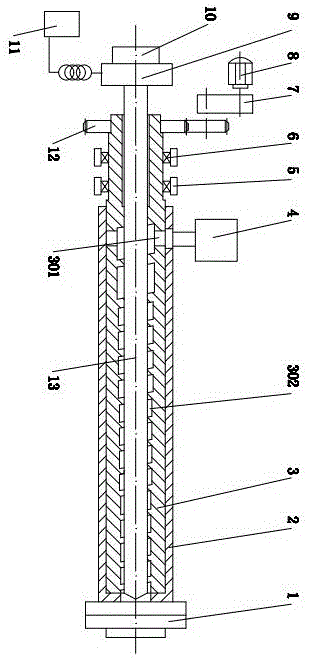

[0024] like figure 1 As shown, it is a hollow single-screw extruder with a vibrating mandrel, including an extruder head 1, a barrel 2, a hollow screw 3, a hopper 4, a seat 5, a radial thrust bearing group 6, and a transmission mechanism 7. Motor 8, vibrator 9, fixed seat 10, motion controller 11, gear 12 and mandrel 13; among them

[0025] The extruder head 1 is installed on the right end of the barrel 2, that is, the outlet end of the barrel 2, and the extruder head 1 communicates with the discharge port of the barrel 2; the hopper 4 is installed on the left end of the barrel 2;

[0026] The hollow screw 3 is located in the barrel 2, has a central hole in the hollow screw 3, and is provided with a radial channel 301 at the left end of the hollow screw 3, and the radial channel 301 communicates with the discharge port of the hopper 4, The inner wall of the central hole of the hollow screw 3 is provided with a continuous inner screw groove 302 that runs through the full lengt...

Embodiment 2

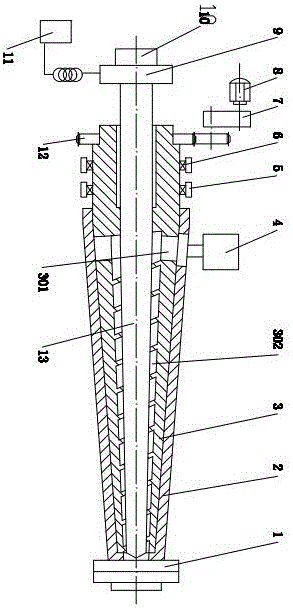

[0033] like figure 2 As shown, it is a hollow single-screw extruder with a vibrating mandrel. Its structure and working principle are basically the same as in Embodiment 1, except that the central hole of the hollow screw 3 is conical, so that the mandrel 13 The shape should be adapted to the shape of the central hole in the hollow screw 3, and the mandrel 13 is also a cone, and the mandrel 13 pulsates and rotates in the center hole of the hollow screw 3 in the circumferential direction or directly rotates in the circumferential direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com