Anti-roll ribbed seal

A technology of seals and sealing structures, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., and can solve the problems of seals that are difficult to detect deformation, time-consuming and expensive to repair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses.

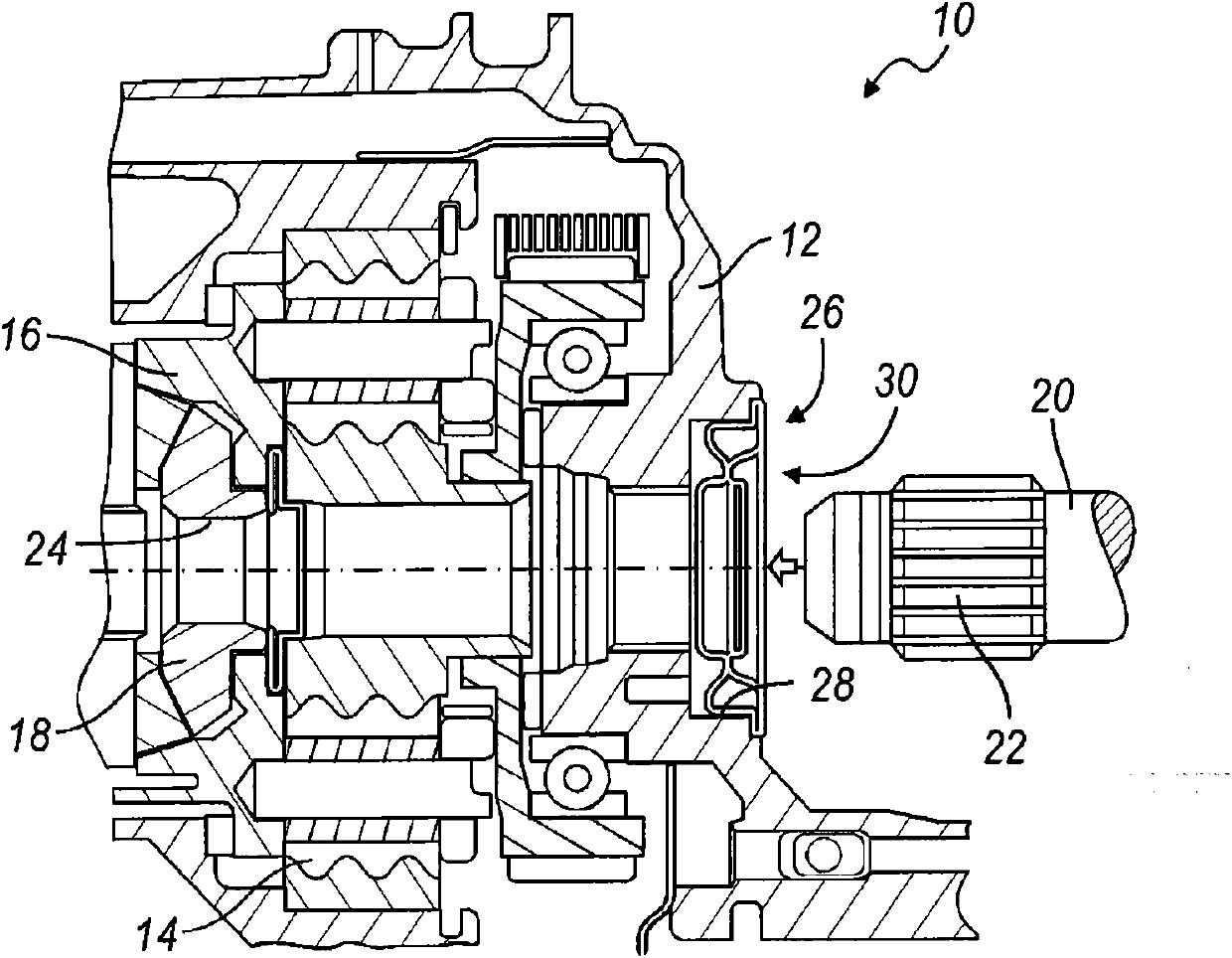

[0045] refer to figure 1, showing a portion of the final drive assembly, including the differential and propshafts, generally indicated at 10 . The final drive assembly 10 includes a housing 12 that receives, positions and protects, for example, an input or driven gear 14 that engages or drives a cowl differential 16 having a pair of Output bevel gear 18, one of output bevel gear 18 is shown in figure 1 . The output bevel gear 18 is drivingly connected to a shaft 20, which is shown before assembly. Shaft 20 includes, for example, external splines 22 that complementarily engage internal splines 24 in bevel gear 18 .

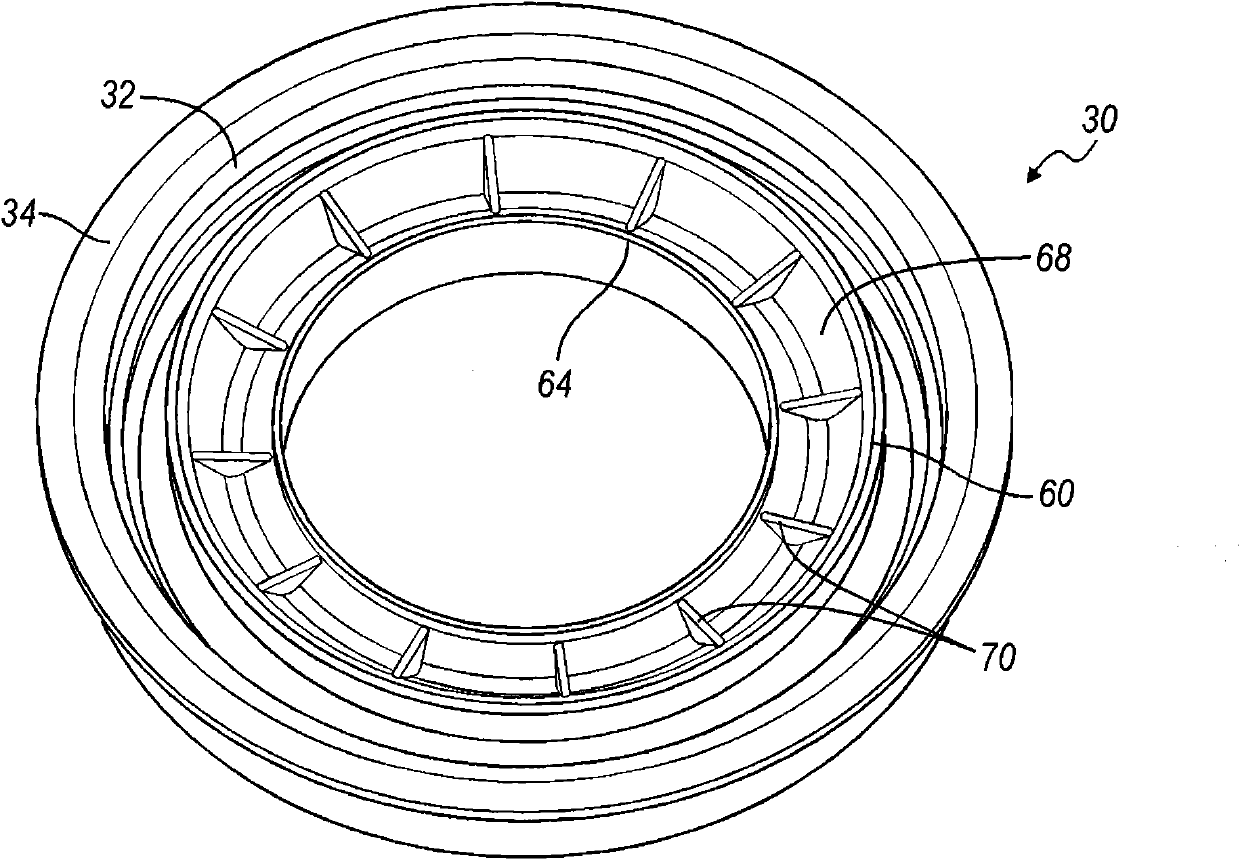

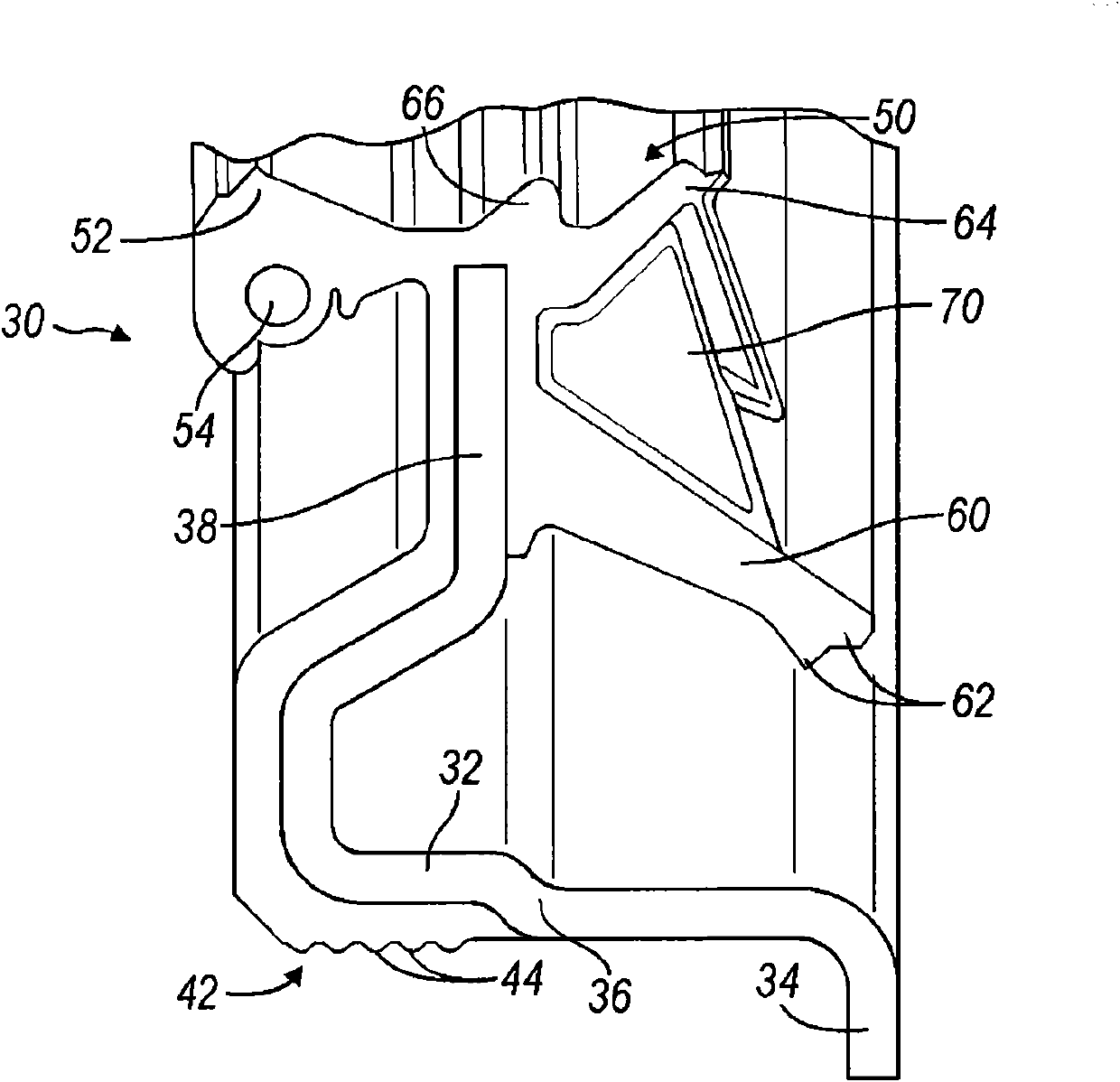

[0046] Housing 12 defines a bore or circular opening 26 that accommodates shaft 20 and a coaxial counterbore 28 that receives a fluid-tight shaft seal 30 in accordance with the present invention. Shaft seal 30 provides a fluid seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com