Locking device of machining tooling for cylinder body part holes

A tooling locking device, part hole technology, applied in the direction of clamping device, positioning device, metal processing equipment, etc., can solve the problems of difficult processing, high size, shape and position tolerance requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Example 1: After the loading rack is pulled out, the compressed spring steel ball enters the hole, and there is no positioning effect. When the loading rack is sent inward, it reaches the fixed position of the guide rail, and the steel ball pops out and gets locked in the locking socket of the loading rack. Tight effect.

Description of the drawings:

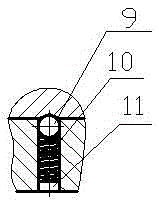

[0007] 9 steel ball; 10, spring; 11, set screws.

[0008] figure 1 It is a schematic diagram of the assembly of the locking device for the hole processing of cylinder parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com