Metal roof mounting structure based on BIM technical design and construction method

A metal roof and installation structure technology, which is applied to roofs, roofs, and roof coverings using flat/curved panels, which can solve problems such as unfavorable installation and maintenance, unfavorable construction of a single roof, and large volume to ensure connection The effect of strength and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

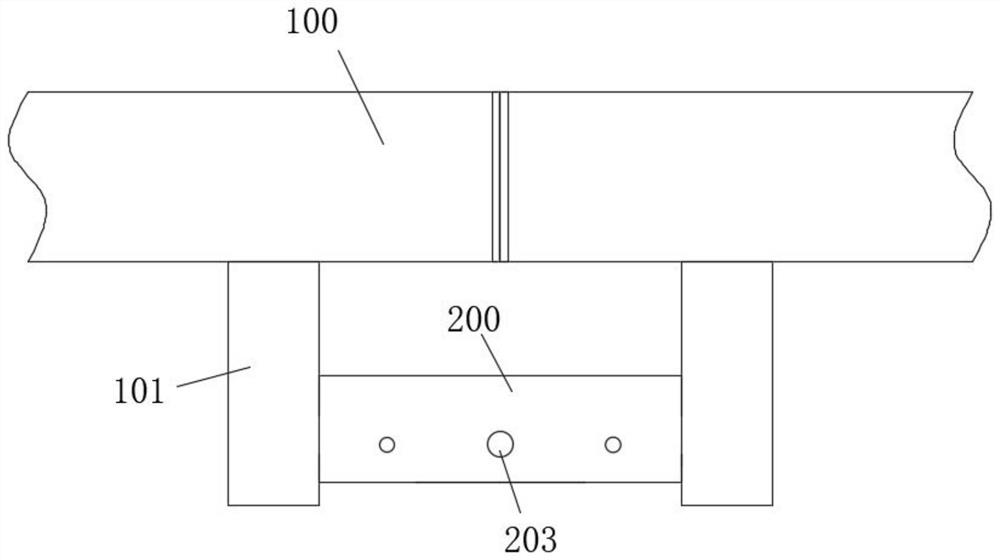

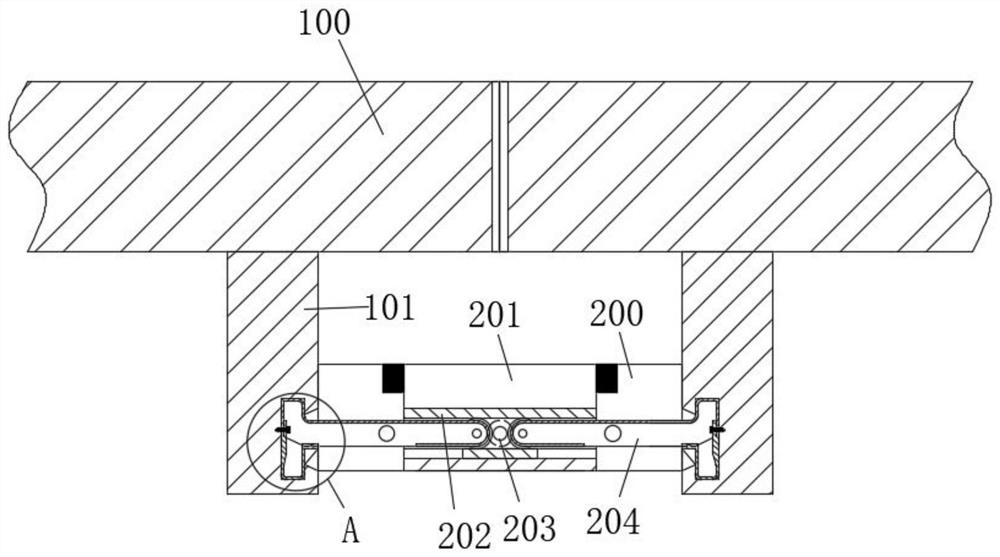

[0033] Such as Figure 1 to Figure 4 As shown, a metal roof installation structure designed based on BIM technology includes several groups of roof units 100 and installation frames 200 connecting two adjacent roof units 100, and the opposite one of the adjacent two groups of roof units 100 Both sides are provided with fixing parts 101, and the outer side walls of each of the fixing parts 101 are provided with installation grooves 102 along the length direction, and the inner sides of the installation frame 200 are rotatably installed with connecting angle claws 204. One end of the connecting claw 204 is adapted to the installation groove 102 after being rotated by a certain angle. The inner side wall of the installation frame 200 is provided with a guide groove 201, and the inside of the guide groove 201 is slidably provided with a push block 202. The push block The two ends of 202 are respectively slidably arranged with the other end of the corresponding connecting claw 204 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com