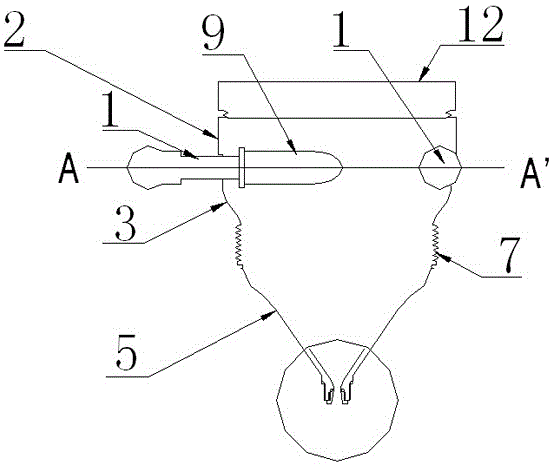

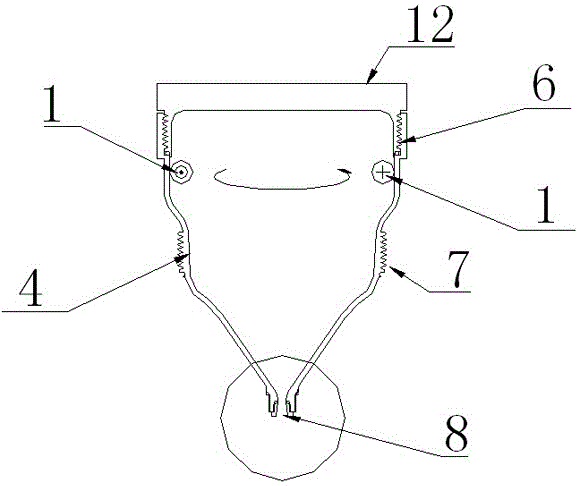

A spray drying device

A technology of drying device and drying tower, applied in spraying device, liquid spraying device, measuring device, etc., can solve the problems of narrow particle size distribution, increased power equipment, and small required pressure, and achieve the droplet particle size distribution range. Narrow, avoid shaft seal problems, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] The basic parameters of this embodiment are as follows.

[0110] The spray drying tower with an annual output of 1300 tons was used for the experiment, and its hydraulic pump flow rate: 12 kg / min; fan flow rate: 130 m 3 / min; air compressor flow rate: 0.3 m 3 / min;

[0111] The diameter of the inner chamber separated by the partition sleeve in the drying tower is 390mm, and the diameter of the outer chamber is 800mm; the height of the partition sleeve is 2290mm, and the height of the drying tower (that is, the height from the top sealing plate to the bottom of the cyclone chamber) is 3600mm.

[0112] The diameter of ordinary single-hole nozzles (4 evenly distributed) on the side wall of the swirl chamber in the middle and lower part of the drying tower: 40 mm;

[0113] The diameter of the ordinary single-hole nozzle (4 uniformly distributed) connected with the fluid delivery pipe to be dried in the dual-fluid high-speed atomization nozzle of the present invention: 1 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com