Dynamic characteristic test device of paired bearing differential cage

A test device and dynamic characteristic technology, which is applied in the direction of mechanical bearing test, measuring device, test of mechanical parts, etc., to achieve the effect of reliable measurement results, high detection accuracy and reasonable structure installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

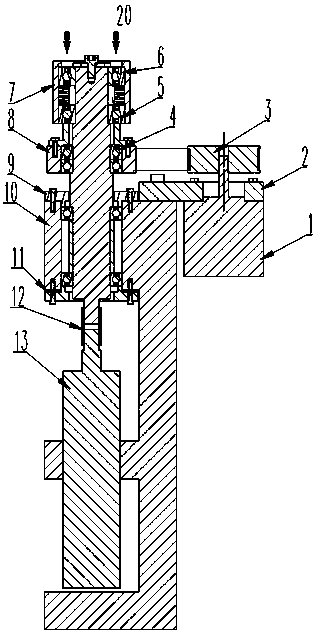

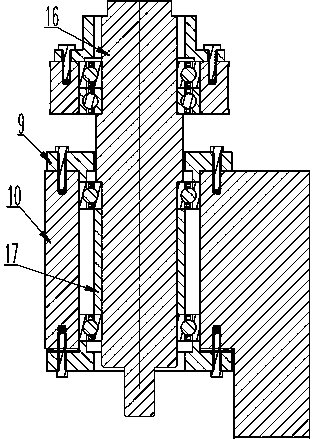

[0030] In this example, see Figure 1~4 , a paired bearing differential cage dynamic characteristic test device, including a driving part, a loading part and a measuring part, a shaft 16 is installed on a bracket 10 of the test device, and two paired bearings are fixedly installed on the shaft 16 to form a paired bearing System, the two paired bearings are composed of the first paired bearing 5 and the second paired bearing 6, the first paired bearing 5 and the second paired bearing 6 are deep groove ball bearings that bear axial force, the first paired bearing Bearing 5 and the second paired bearing 6 are paired bearings composed of a pair of bearings of the same size. The paired bearings are installed back to back, and the inner and outer rings of the two paired bearings are respectively connected and rotated synchronously through the loading part. The outer rings of the first matching bearing 5 and the second matching bearing 6 are fixedly connected by a sleeve 7, and the o...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this embodiment, the first paired bearing 5 and the second paired bearing 6 are angular contact ball bearings, and the first paired bearing 5 and the second paired bearing of the differential cage dynamic characteristic test device The bearings 6 are installed in series, and the outer rings are connected through the sleeve 7. The sleeve can ensure the coaxiality of the outer rings of the first matching bearing 5 and the second matching bearing 6. By controlling the speed of the cage of the first matching bearing 5, Just can make the inner ring drive the outer ring to rotate through the friction between the ball and the raceway, and realize the reverse rotation of the inner and outer rings of the second matching bearing 6 . The electric spindle 13 is connected to the shaft 16 through the coupling 12, the stepper motor 1 is connected to the cage connection sleeve 19 through the synchron...

Embodiment 3

[0044] This embodiment is basically the same as the previous embodiment, and the special features are:

[0045] In this embodiment, the first paired bearing 5 and the second paired bearing 6 use a pair of bearings of different sizes to form a paired bearing, and are installed on the stepped shaft section of the shaft 16 . When the paired bearings of this embodiment are chosen to be inconsistent in size, the test device of this embodiment can still study the dynamic characteristics of the cage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com