Squid bone seafood sauce and preparation method thereof

A technology of seafood soy sauce and squid, which is applied in the direction of food ingredients as taste improvers, food science, etc., can solve the problems of unusable, squid bone protein waste, and value cannot be reflected, and achieve the effect of outstanding flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

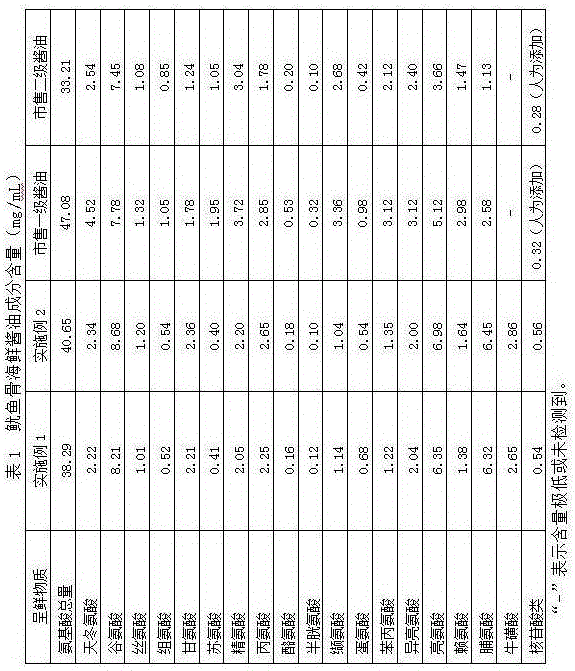

Examples

Embodiment 1

[0020] 1) The squid bone enzymatic hydrolyzate is prepared by the following steps: the squid bone is washed with water, dried naturally, then frozen in an ultra-low temperature refrigerator, and then freeze-dried. 80 mesh sieve is required. The obtained squid bone powder is hydrolyzed with neutral protease, and the enzyme activity of neutral protease is 50000IU / g. During enzymolysis, 10g squid bone powder and 0.005g neutral protease are added in every 100 milliliters of water, that is, the corresponding enzyme activity per unit mass of squid bone is 250IU / g. g (based on 100mL water), enzymolysis time 3h, enzymolysis temperature 40℃. After enzymolysis, heat up to 100°C and keep for 10 minutes to inactivate the enzyme. After the enzymolysis product is filtered, take the liquid part, and after concentration, dry it on a spray dryer. The drying conditions are as follows: inlet air temperature 180°C, outlet air temperature 80°C The volume is controlled at 3mL / min. After spray dry...

Embodiment 2

[0026] 1) The squid bone enzymatic hydrolyzate is prepared by the following steps: the squid bone is washed with water, dried naturally, then frozen in an ultra-low temperature refrigerator, and then freeze-dried. It is required to pass through an 80-mesh sieve, and the obtained squid bone powder is hydrolyzed with neutral protease, and the enzyme activity of neutral protease is 50000IU / g. During enzymolysis, 10g squid bone powder and 0.01g neutral protease are added to every 100 ml of water, that is, squid bone per unit mass corresponds to The enzyme activity is 500IU / g (based on 100mL water), the enzymolysis time is 2h, the enzymolysis temperature is 40°C, after the enzymolysis is completed, the temperature is raised to 100°C, and the enzyme is kept for 10min to inactivate the enzyme. After the enzymolysis product is filtered, the liquid part is taken. After concentration, it is dried in a spray dryer. The drying conditions are that the air inlet temperature is 180°C, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com