Method and device for detecting powder jet characteristics

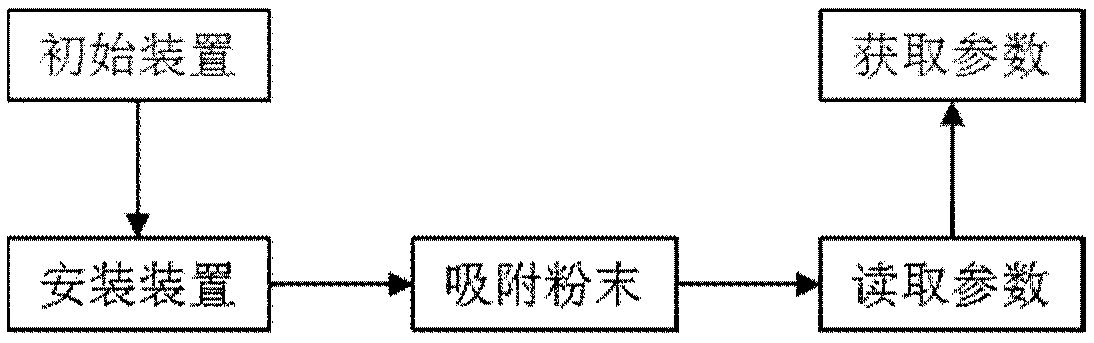

A detection device and detection method technology, applied in the direction of measuring devices, material absorption weighing, instruments, etc., can solve the problems that the detection method cannot fully meet the needs of high-speed powder jet detection, accuracy, cycle impact, etc., and achieve low cost and adaptability Strong, full preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

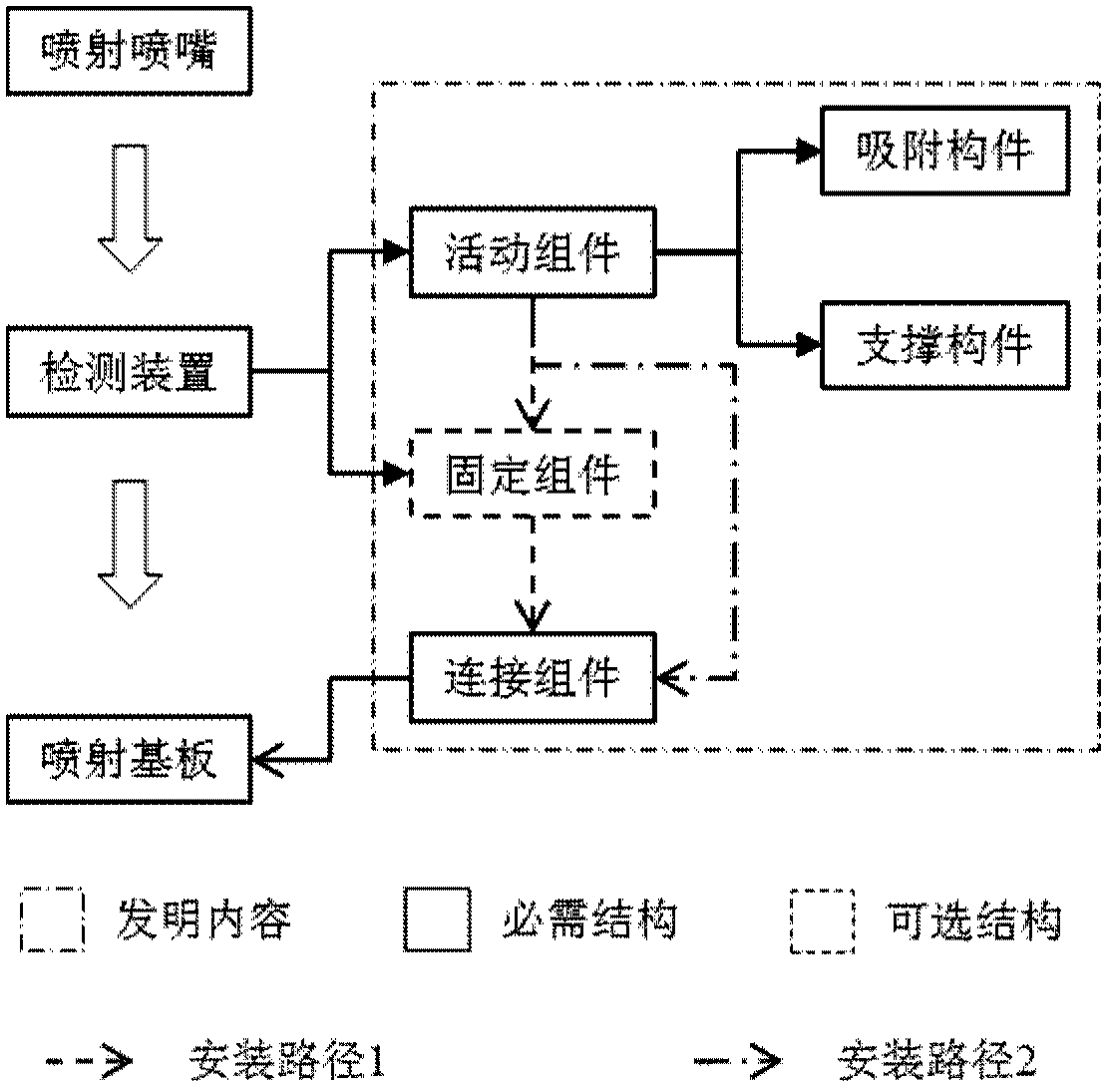

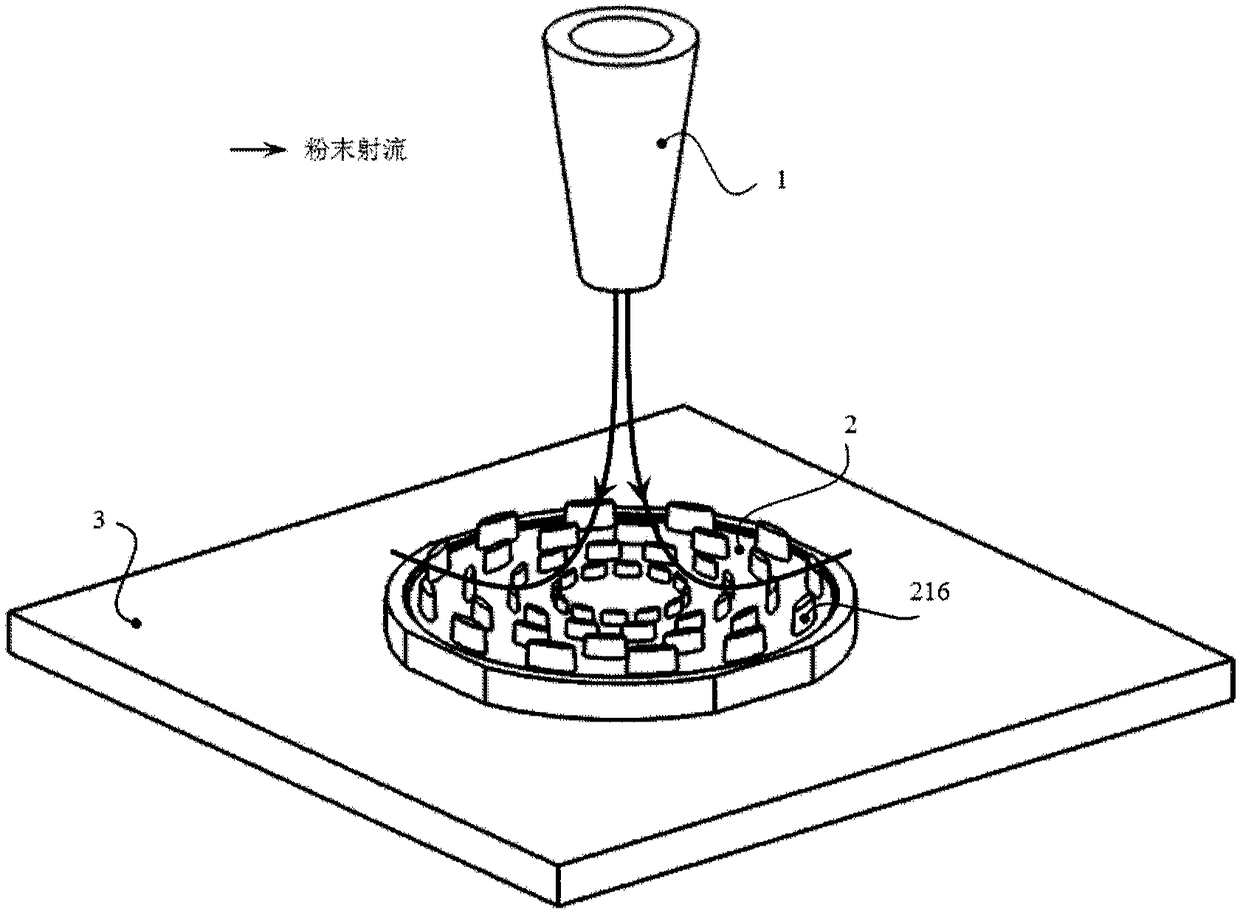

[0037] According to the general inventive concept of the present invention, a detection device for powder jet characteristics is provided, including: a movable assembly, which includes an adsorption member and a support member, the adsorption member is set to absorb powder in the jet, and the support member is set to The adsorption member is supported; the connection assembly is used to fix the movable assembly to the ejection substrate.

[0038] Among them, the movable component and the connecting component are required structures, and the fixed component is optional according to the detection requirements. The movable component is the main part of the detection device, which is used to complete the main functions of the detection device such as powder adsorption and parameter measurement; the connecting component fixes the movable component to the spray substrate; the fixed component provides auxiliary functions such as precise positioning and temperature control. In a typic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com