Quality evaluation method of CFRP cut and machined surface at full-range fiber orientation angle

A fiber orientation and cutting technology used in the field of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited to the following embodiments.

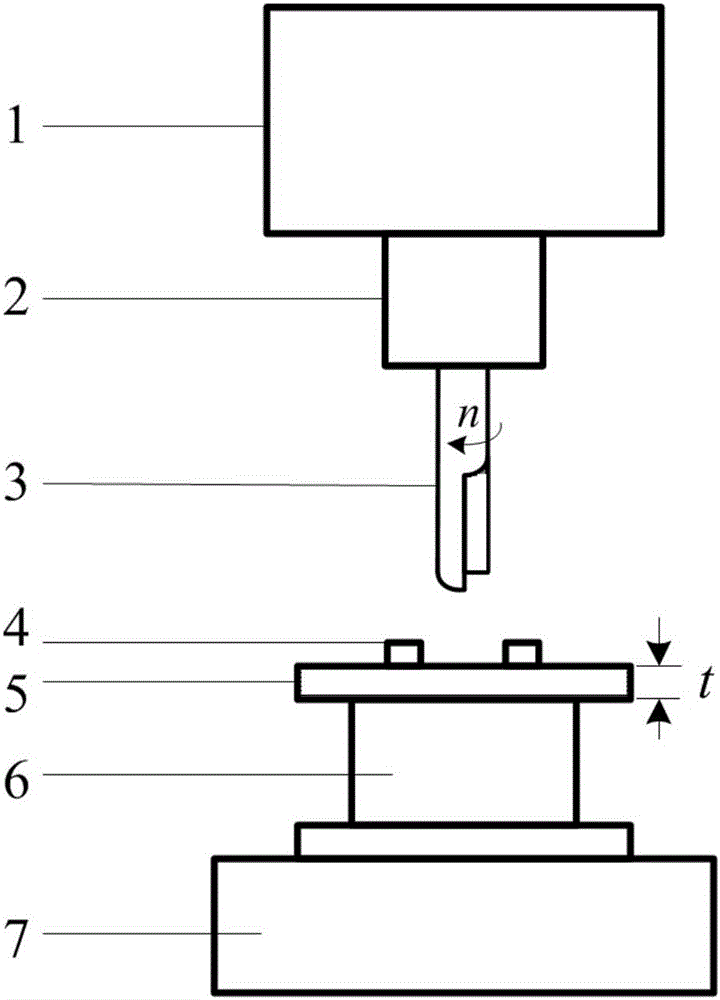

[0025] The evaluation method of the CFRP cutting surface quality of the full range of fiber direction angles in the present invention is to obtain the cutting surface of the carbon fiber reinforced composite materials under the full range of fiber direction angles by annularly milling the disc workpiece of the carbon fiber reinforced composite material, and the carbon fiber Surface quality evaluation of the machined surface under different fiber orientation angles of reinforced composites. The processing track of the circular milling is a circular track with the center of the disc workpiece as the center, and the disc workpiece is a carbon fiber reinforced composite material unidirectional laminated plate laminated in the same direction.

[0026] The full-ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com