Automatic recycling and placing vehicle for traffic road cones

An automatic retractable, traffic road technology, applied in traffic signals, roads, roads, etc., can solve the problems of high manufacturing cost, complex structural design, difficult to popularize, etc., and achieve the effect of high accuracy, high degree of automation, and accurate recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

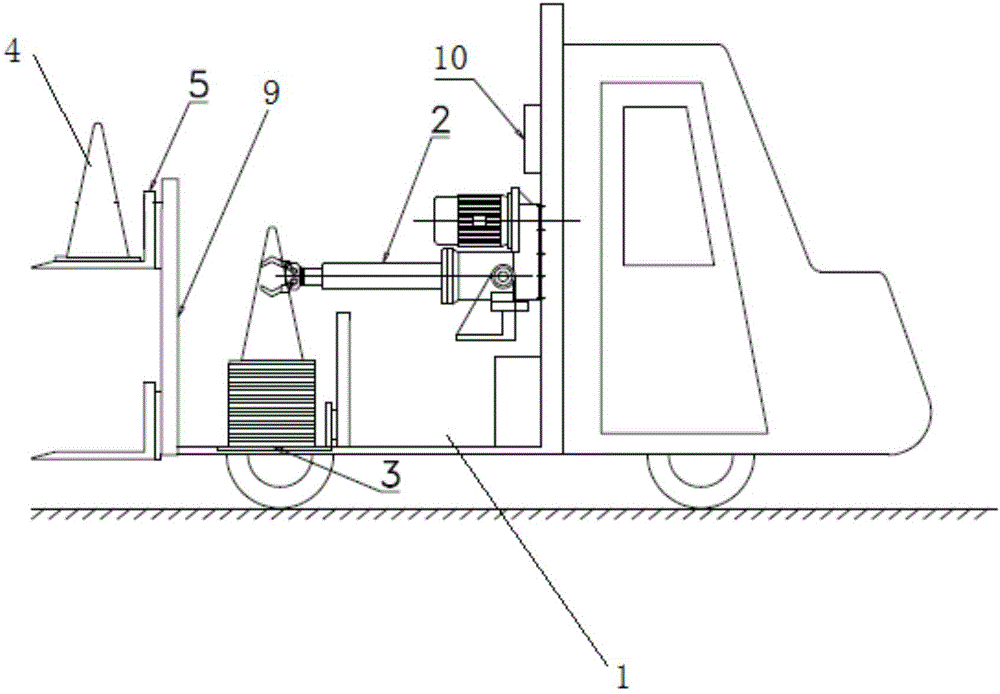

[0032] An automatic retractable vehicle for traffic road cones, comprising a vehicle body 1, and a dispensing device, a recovery device and an intelligent control cabinet 10 arranged on the vehicle body 1 , both the dispensing device and the recovery device are connected to the intelligent control cabinet 10 .

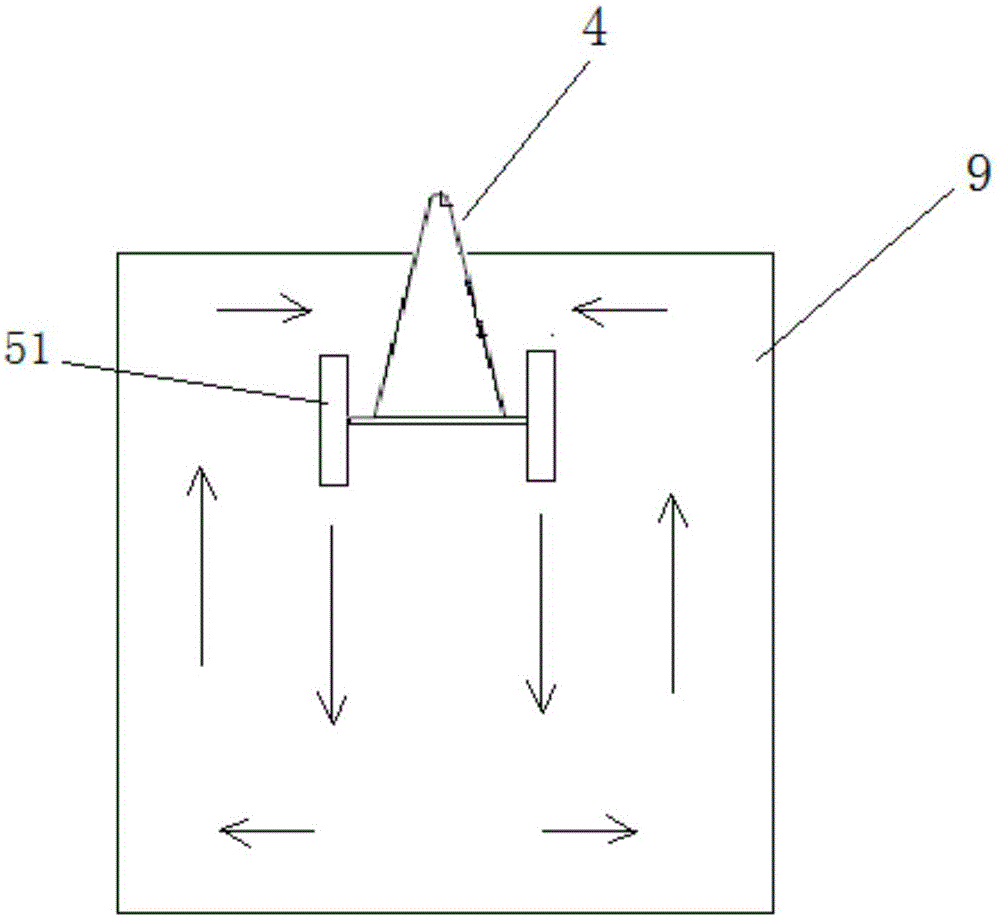

[0033] The release device has a structure such as figure 1 shown, and see image 3 , including manipulator 2, automatic lifting assembly 3 and forklift assembly 5. The automatic lifting component 3 is arranged on the bottom plate of the car body 1, and a plurality of traffic cones 4 are placed on the automatic lifting component 3. The automatic lifting component 3 is a lifting platform driven by a lifting motor to move up and down. The lifting motor and intelligent control Cabinet 10 is connected, and traffic road cone 4 is placed on the lifting platform. The up and down movement of the lifting platform satisfies: after the manipulator 2 grabs a traffic cone 4 every ...

Embodiment 2

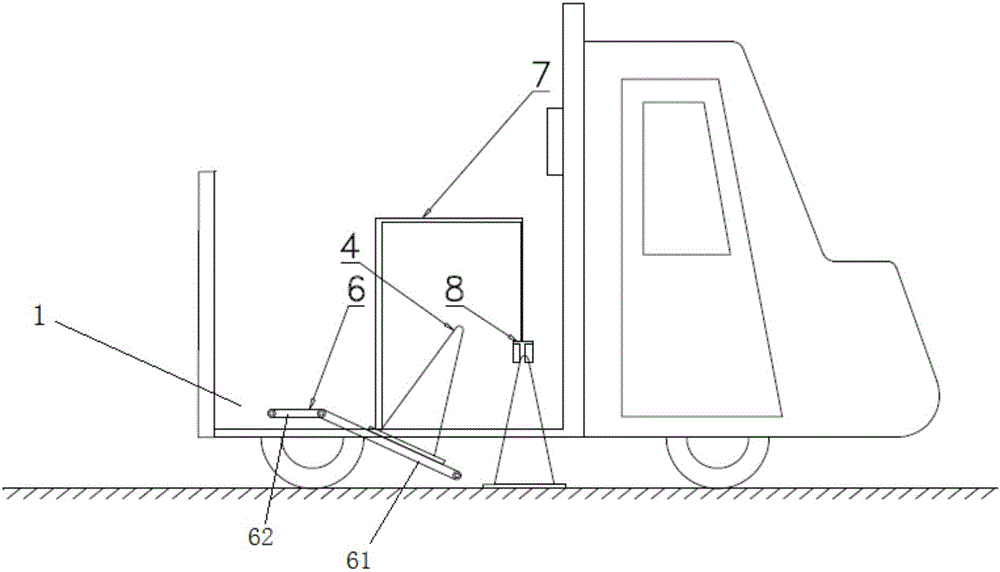

[0043] An automatic retractable vehicle for traffic road cones, comprising a vehicle body 1, and a dispensing device, a recovery device and an intelligent control cabinet 10 arranged on the vehicle body 1 , both the dispensing device and the recovery device are connected to the intelligent control cabinet 10 .

[0044] The dispensing device includes a manipulator 2 , an automatic lifting assembly 3 and a forklift assembly 5 . The automatic lifting component 3 is arranged on the bottom plate of the car body 1, and a plurality of traffic cones 4 are placed on the automatic lifting component 3. The automatic lifting component 3 is a lifting platform driven by a lifting motor to move up and down. The lifting motor and intelligent control Cabinet 10 is connected, and traffic road cone 4 is placed on the lifting platform. The up and down movement of the lifting platform satisfies: after the manipulator 2 grabs a traffic cone 4 every time, the lifting platform moves up a distance equ...

Embodiment 3

[0054] An automatic retractable vehicle for traffic road cones, comprising a vehicle body 1, and a dispensing device, a recovery device and an intelligent control cabinet 10 arranged on the vehicle body 1 , both the dispensing device and the recovery device are connected to the intelligent control cabinet 10 .

[0055] The dispensing device includes a manipulator 2 , an automatic lifting assembly 3 and a forklift assembly 5 . The automatic lifting component 3 is arranged on the bottom plate of the car body 1, and a plurality of traffic cones 4 are placed on the automatic lifting component 3. The automatic lifting component 3 is a lifting platform driven by a lifting motor to move up and down. The lifting motor and intelligent control Cabinet 10 is connected, and traffic road cone 4 is placed on the lifting platform. The up and down movement of the lifting platform satisfies: after the manipulator 2 grabs a traffic cone 4 every time, the lifting platform moves up a distance equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com