A high temperature oxidation resistant thermal barrier coating with composite structure and its preparation method

A high-temperature oxidation-resistant, composite structure technology, applied in chemical instruments and methods, coatings, metal material coating processes, etc., can solve the problems of high-temperature oxidation-resistant thermal barrier coatings with good repeatability, and achieve high-temperature oxidation resistance Excellent, repeatable, simple process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

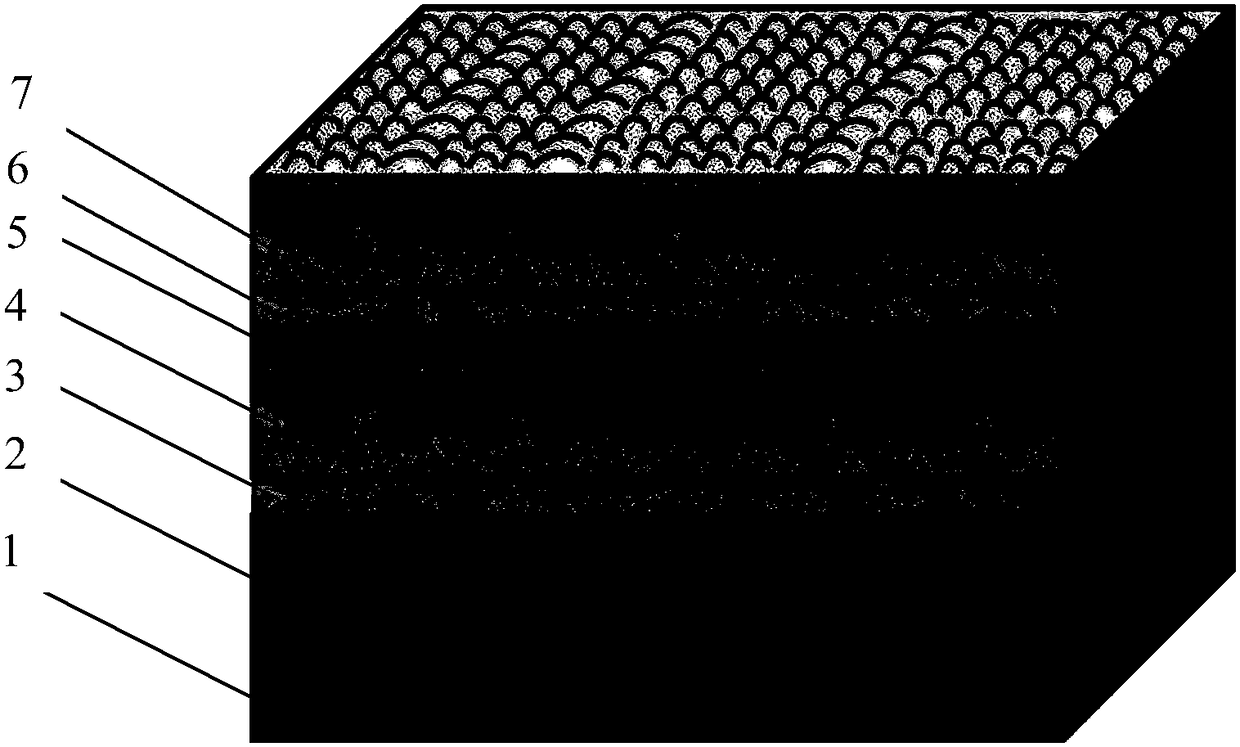

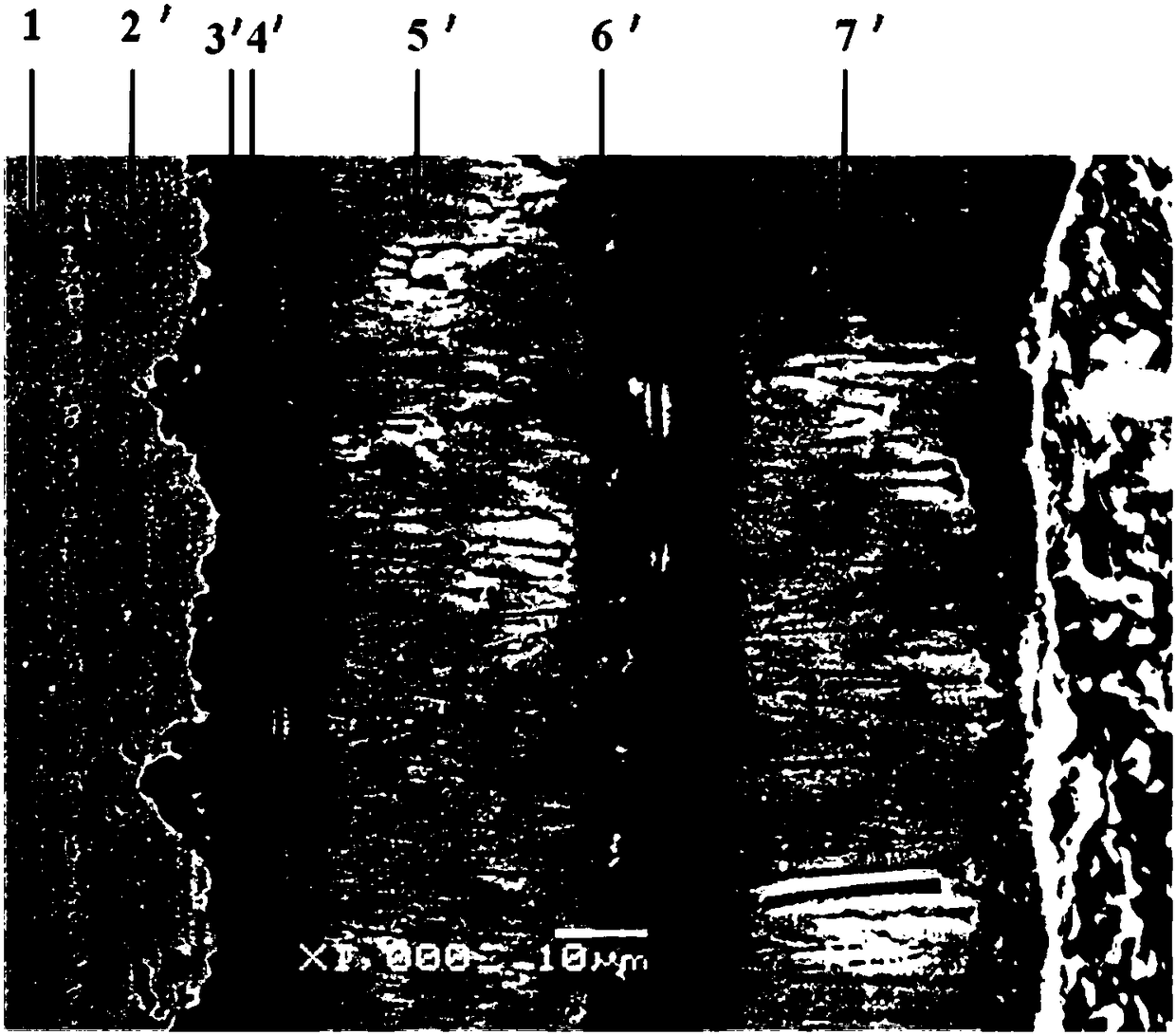

[0033] like figure 1 As shown, the high temperature oxidation resistant thermal barrier coating with a composite structure in this embodiment is deposited on the top of the superalloy substrate 1, and the coating includes a metal bonding layer 2, a first ceramic layer 3, and a second ceramic layer deposited sequentially from bottom to top. Two ceramic layers 4, a metal deposition layer 5, a third ceramic layer 6 and a fourth ceramic layer 7, the first ceramic layer 3 and the third ceramic layer 6 are equiaxed crystal structures, the second ceramic layer 4 and The fourth ceramic layer 7 is a columnar crystal structure; the composition of the first ceramic layer 3, the second ceramic layer 4, the third ceramic layer 6 and the fourth ceramic layer 7 is 6wt% ~ 8wt% Y 2 o 3 Stable ZrO 2, the composition of the metal bonding layer 2 is MCrAlY, the composition of the metal deposition layer 5 is MCrAlY, and M is Ni or / and Co.

[0034] In this embodiment, M is Ni; the thickness of t...

Embodiment 2

[0045] like figure 1 As shown, the high temperature oxidation resistant thermal barrier coating with a composite structure in this embodiment is deposited on the top of the superalloy substrate 1, and the coating includes a metal bonding layer 2, a first ceramic layer 3, and a second ceramic layer deposited sequentially from bottom to top. Two ceramic layers 4, a metal deposition layer 5, a third ceramic layer 6 and a fourth ceramic layer 7, the first ceramic layer 3 and the third ceramic layer 6 are equiaxed crystal structures, the second ceramic layer 4 and The fourth ceramic layer 7 is a columnar crystal structure; the composition of the first ceramic layer 3, the second ceramic layer 4, the third ceramic layer 6 and the fourth ceramic layer 7 is 6wt% ~ 8wt% Y 2 o 3 Stable ZrO 2 , the composition of the metal bonding layer 2 is MCrAlY, the composition of the metal deposition layer 5 is MCrAlY, and M is Ni or / and Co.

[0046] In this embodiment, M is Ni and Co; the thickn...

Embodiment 3

[0056] like figure 1 As shown, the high temperature oxidation resistant thermal barrier coating with a composite structure in this embodiment is deposited on the top of the superalloy substrate 1, and the coating includes a metal bonding layer 2, a first ceramic layer 3, and a second ceramic layer deposited sequentially from bottom to top. Two ceramic layers 4, a metal deposition layer 5, a third ceramic layer 6 and a fourth ceramic layer 7, the first ceramic layer 3 and the third ceramic layer 6 are equiaxed crystal structures, the second ceramic layer 4 and The fourth ceramic layer 7 is a columnar crystal structure; the composition of the first ceramic layer 3, the second ceramic layer 4, the third ceramic layer 6 and the fourth ceramic layer 7 is 6wt% ~ 8wt% Y 2 o 3 Stable ZrO 2 , the composition of the metal bonding layer 2 is MCrAlY, the composition of the metal deposition layer 5 is MCrAlY, and M is Ni or / and Co.

[0057]In this embodiment, M is Co; the thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com