High temperature oxidation-resistant thermal barrier coating layer with composite structure and preparation method thereof

A technology of anti-high temperature oxidation and composite structure, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of good repeatability and high temperature oxidation resistance thermal barrier coating, and achieve high temperature oxidation resistance Excellent, low oxygen permeability, the effect of improving the interface binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

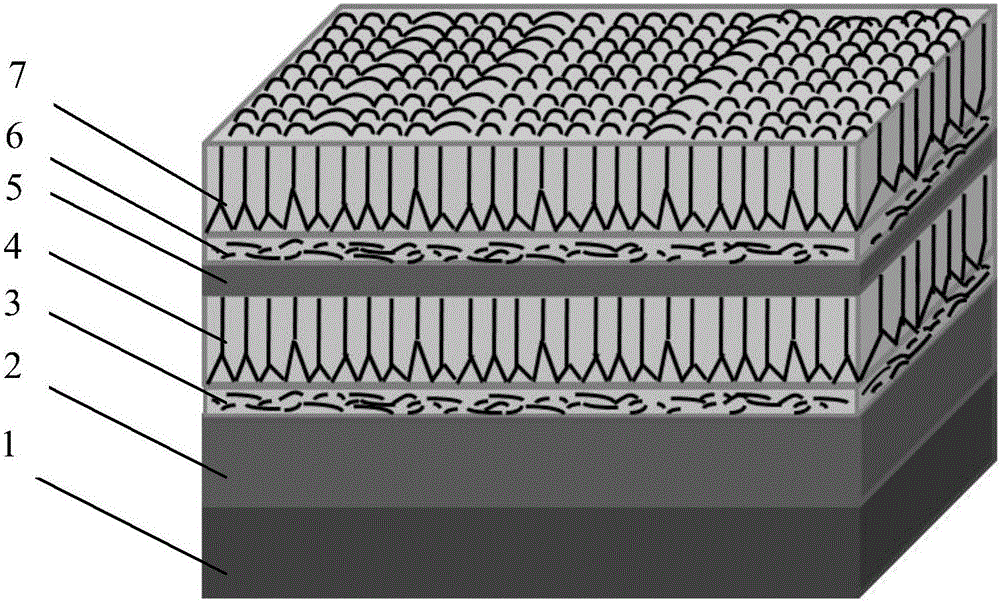

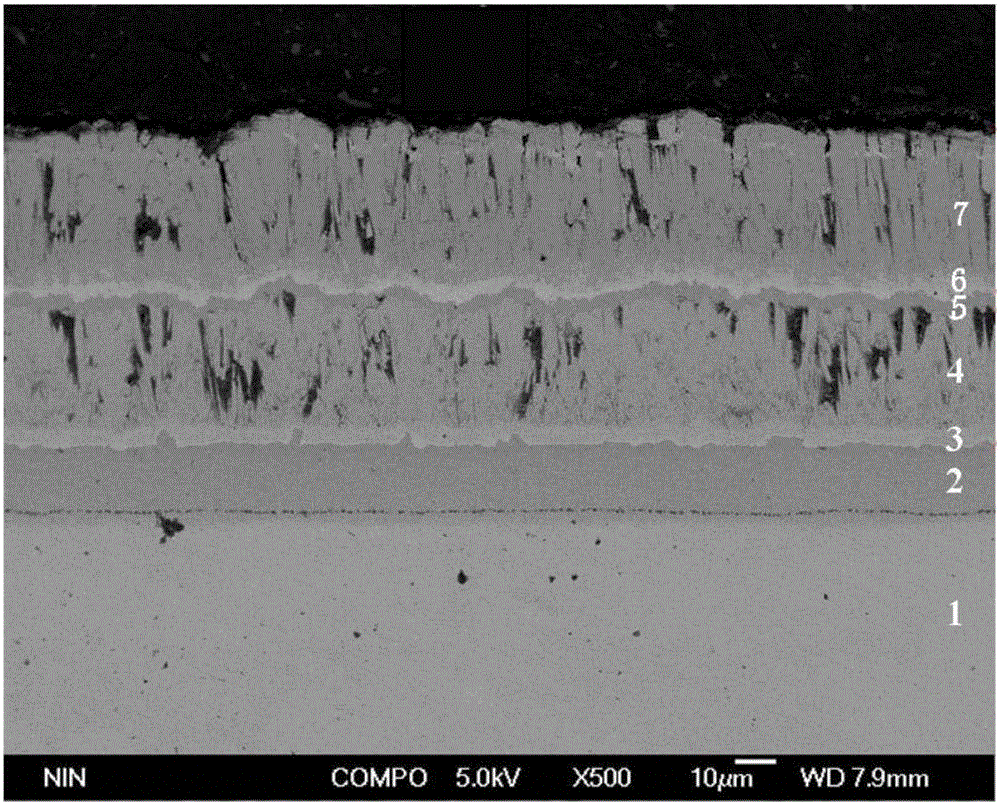

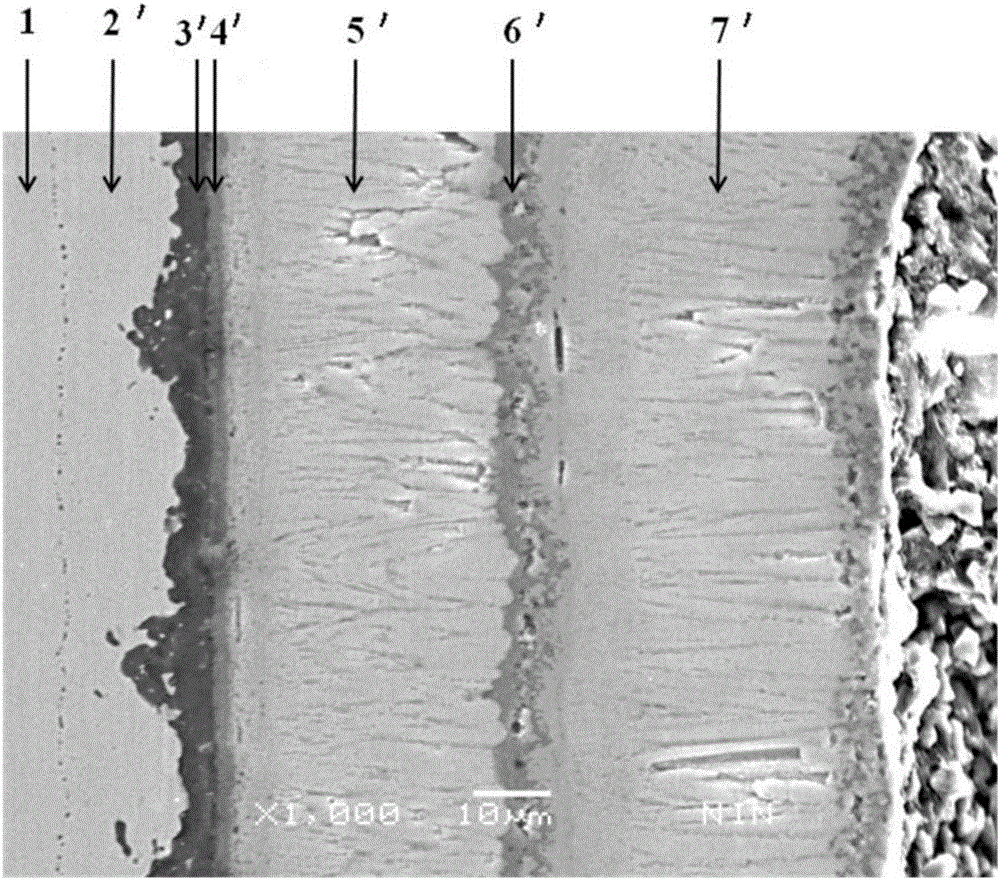

[0033] Such as figure 1 As shown, the high temperature oxidation resistant thermal barrier coating with a composite structure in this embodiment is deposited on the top of the superalloy substrate 1, and the coating includes a metal bonding layer 2, a first ceramic layer 3, and a second ceramic layer deposited sequentially from bottom to top. Two ceramic layers 4, a metal deposition layer 5, a third ceramic layer 6 and a fourth ceramic layer 7, the first ceramic layer 3 and the third ceramic layer 6 are equiaxed crystal structures, the second ceramic layer 4 and The fourth ceramic layer 7 is a columnar crystal structure; the composition of the first ceramic layer 3, the second ceramic layer 4, the third ceramic layer 6 and the fourth ceramic layer 7 is 6wt% ~ 8wt% Y 2 o 3 Stable ZrO 2, the composition of the metal bonding layer 2 is MCrAlY, the composition of the metal deposition layer 5 is MCrAlY, and M is Ni or / and Co.

[0034] In this embodiment, M is Ni; the thickness o...

Embodiment 2

[0045] Such as figure 1 As shown, the high temperature oxidation resistant thermal barrier coating with a composite structure in this embodiment is deposited on the top of the superalloy substrate 1, and the coating includes a metal bonding layer 2, a first ceramic layer 3, and a second ceramic layer deposited sequentially from bottom to top. Two ceramic layers 4, a metal deposition layer 5, a third ceramic layer 6 and a fourth ceramic layer 7, the first ceramic layer 3 and the third ceramic layer 6 are equiaxed crystal structures, the second ceramic layer 4 and The fourth ceramic layer 7 is a columnar crystal structure; the composition of the first ceramic layer 3, the second ceramic layer 4, the third ceramic layer 6 and the fourth ceramic layer 7 is 6wt% ~ 8wt% Y 2 o 3 Stable ZrO 2 , the composition of the metal bonding layer 2 is MCrAlY, the composition of the metal deposition layer 5 is MCrAlY, and M is Ni or / and Co.

[0046] In this embodiment, M is Ni and Co; the thi...

Embodiment 3

[0056] Such as figure 1 As shown, the high temperature oxidation resistant thermal barrier coating with a composite structure in this embodiment is deposited on the top of the superalloy substrate 1, and the coating includes a metal bonding layer 2, a first ceramic layer 3, and a second ceramic layer deposited sequentially from bottom to top. Two ceramic layers 4, a metal deposition layer 5, a third ceramic layer 6 and a fourth ceramic layer 7, the first ceramic layer 3 and the third ceramic layer 6 are equiaxed crystal structures, the second ceramic layer 4 and The fourth ceramic layer 7 is a columnar crystal structure; the composition of the first ceramic layer 3, the second ceramic layer 4, the third ceramic layer 6 and the fourth ceramic layer 7 is 6wt% ~ 8wt% Y 2 o 3 Stable ZrO 2 , the composition of the metal bonding layer 2 is MCrAlY, the composition of the metal deposition layer 5 is MCrAlY, and M is Ni or / and Co.

[0057]In this embodiment, M is Co; the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com