Nano-diamond reinforced titanium-based composite material

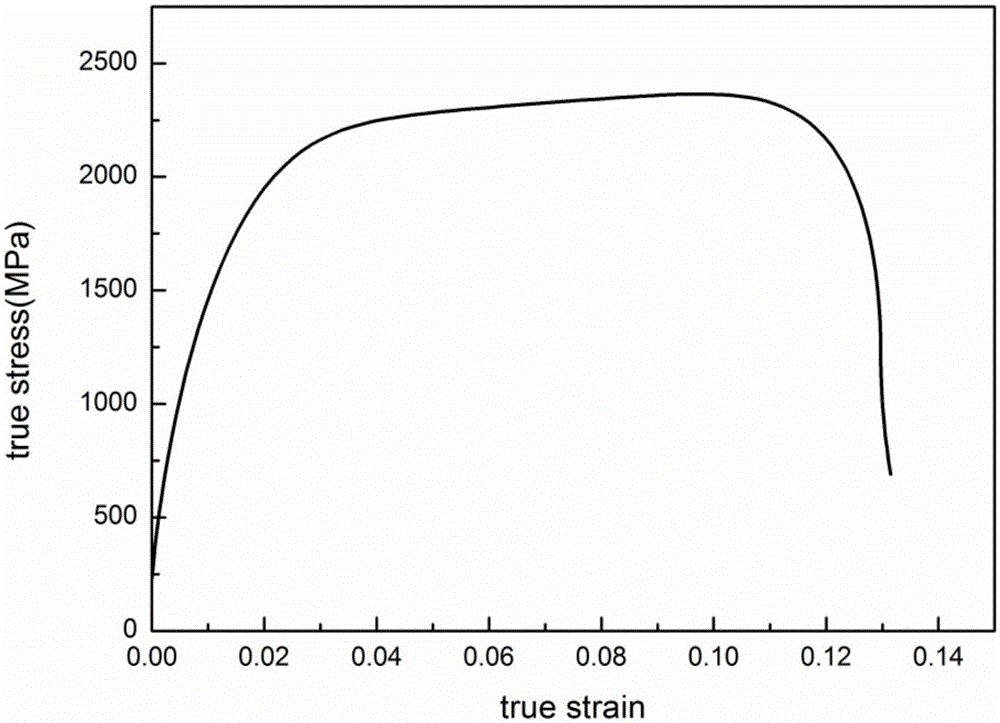

A titanium-based composite material and nano-diamond technology, which is applied in the fields of nano-diamond reinforced titanium-based composite materials and titanium carbide-reinforced titanium-based composite materials, can solve problems such as imperfect research, and achieve improved dynamic mechanical properties and high dynamic strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

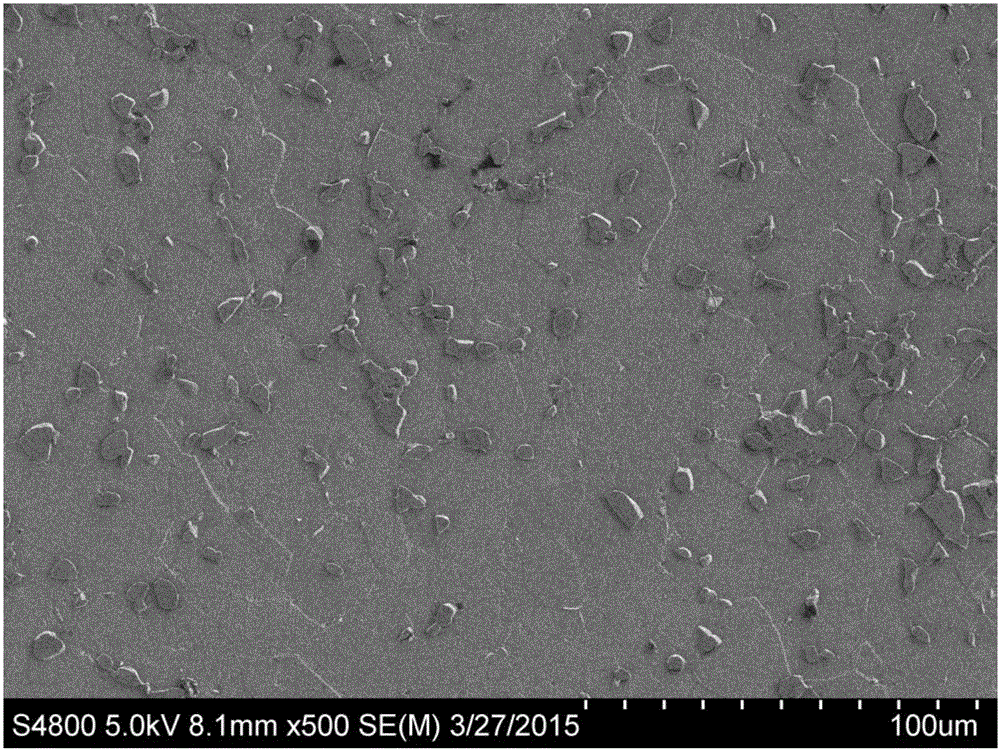

[0046] (1) Powder treatment: take by weighing 0.234g of nano-diamond powder and 29.766g of titanium powder to obtain 30g mixed powder, wherein the volume percentage of nano-diamond powder is 1.8%, put the mixed powder into a ball mill jar, add dehydrated alcohol As a dispersion medium, ZrO with a diameter of 3 mm was added to the ball mill jar 2 Balls 300g to make ZrO 2 The mass ratio of the balls to the mixed powder is 10:1; the ball mill jar is placed on a planetary ball mill, run at a speed of 300r / min, and the ball mill is mixed for 6 hours to obtain a slurry, which is removed by a rotary evaporator at 65r / min at 75°C absolute ethanol in the slurry to obtain a powder; dry the powder in a vacuum oven at 100°C for 12 hours to obtain a dry powder;

[0047] (2) Hot-press sintering: Grind the dry powder to get a uniformly mixed powder, put it into a graphite mold, put it into a hot-press furnace with argon protection atmosphere for hot-press sintering, raise the temperature to...

Embodiment 2

[0052] (1) Powder treatment: take by weighing 0.234g of nano-diamond powder and 29.766g of titanium powder to obtain 30g mixed powder, wherein the volume percentage of nano-diamond powder is 1.8%, put the mixed powder into a ball mill jar, add dehydrated alcohol As a dispersion medium, ZrO with a diameter of 3 mm was added to the tank 2 Balls 300g to make ZrO 2The mass ratio of the balls to the mixed powder is 10:1; the ball mill jar is placed on a planetary ball mill, run at a speed of 400r / min, and the ball mill is mixed for 2 hours to obtain a slurry, which is removed by a rotary evaporator at 65r / min at 75°C absolute ethanol in the slurry to obtain a powder; dry the powder in a vacuum oven at 100°C for 12 hours to obtain a dry powder;

[0053] (2) Hot-press sintering: Grind the dry powder to get a uniformly mixed powder, put it into a graphite mold, put it into a hot-press furnace with argon protection atmosphere for hot-press sintering, raise the temperature to 1300°C, t...

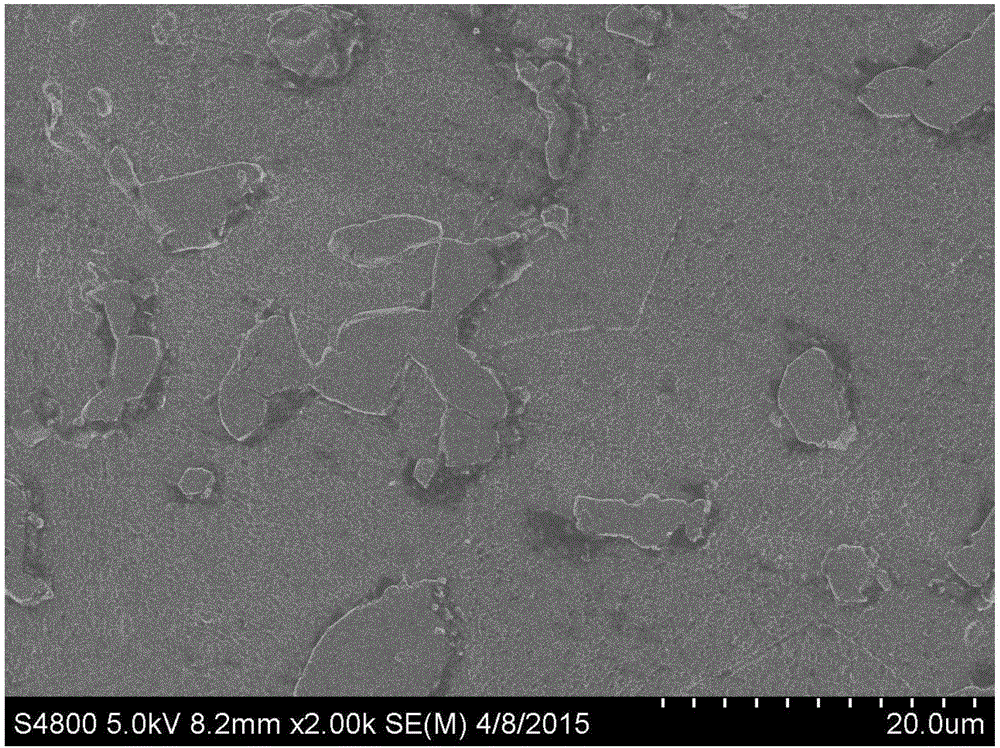

Embodiment 3

[0058] (1) Powder treatment: take by weighing 0.234g of nano-diamond powder and 29.766g of titanium powder to obtain 30g mixed powder, wherein the volume percentage of nano-diamond powder is 1.8%, the mixed powder is put into a ball mill jar, and dehydrated alcohol is added as dispersion medium. Add ZrO with a diameter of 3mm to the tank 2 Ceramic ball 300g, ZrO 2 The mass ratio of the balls to the mixed powder is 10:1; the ball mill jar is placed on a planetary ball mill, run at a speed of 400r / min, and the ball mill is mixed for 6 hours to obtain a slurry, which is removed by a rotary evaporator at 65r / min at 75°C absolute ethanol in the slurry to obtain a powder; dry the powder in a vacuum oven at 100°C for 12 hours to obtain a dry powder;

[0059] (2) Hot-press sintering: Grind the dry powder to get a uniformly mixed powder, put it into a graphite mold, put it into a hot-press furnace with argon protection atmosphere for hot-press sintering, raise the temperature to 900°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strain rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com