Magnetic refrigeration HoxTbyMz high-entropy alloy and preparation method thereof

A high-entropy alloy and magnetic refrigeration technology, applied in the field of magnetic refrigeration alloys, can solve the problems of inventing magnetic refrigeration alloys, large economic burdens, materials that are difficult to change large magnetic entropy, etc., and achieves a wide range of applicable temperature and cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Commercially available rare earth metals Gd, Er, Dy, Ho, Tb are used as starting materials. Use a vacuum non-consumable tungsten electric arc furnace to melt the alloy, and evacuate the sample chamber. When the vacuum degree reaches 5*10 -3 After Pa, rush into the industrial argon until the pressure in the furnace reaches half an atmosphere;

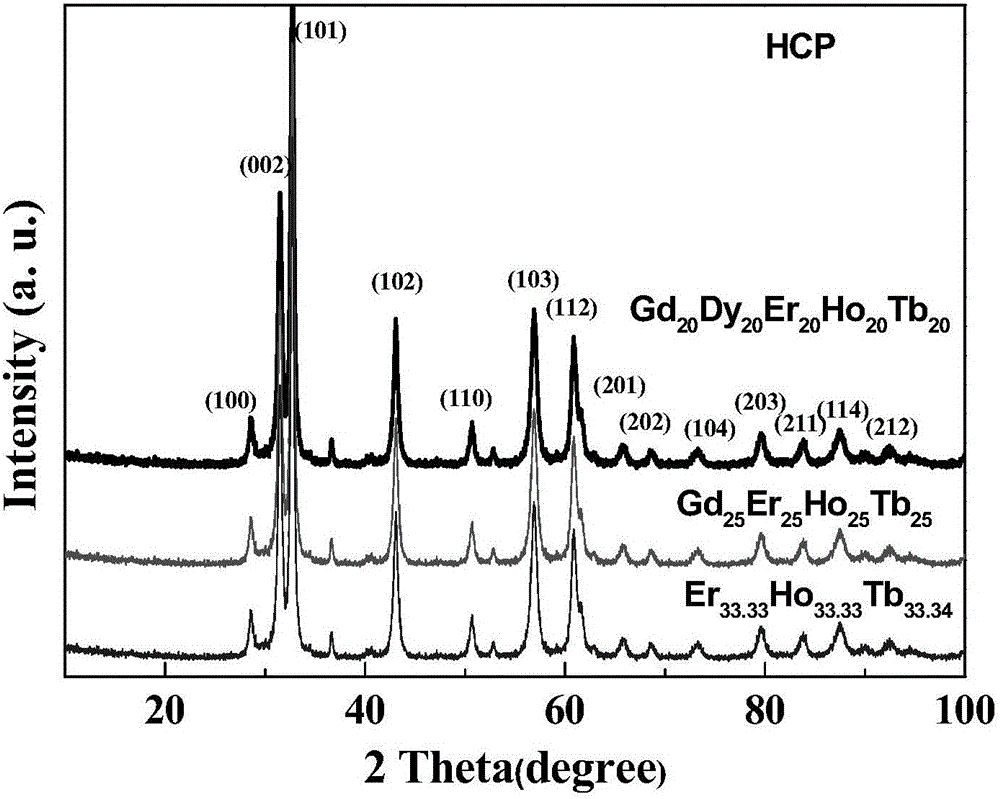

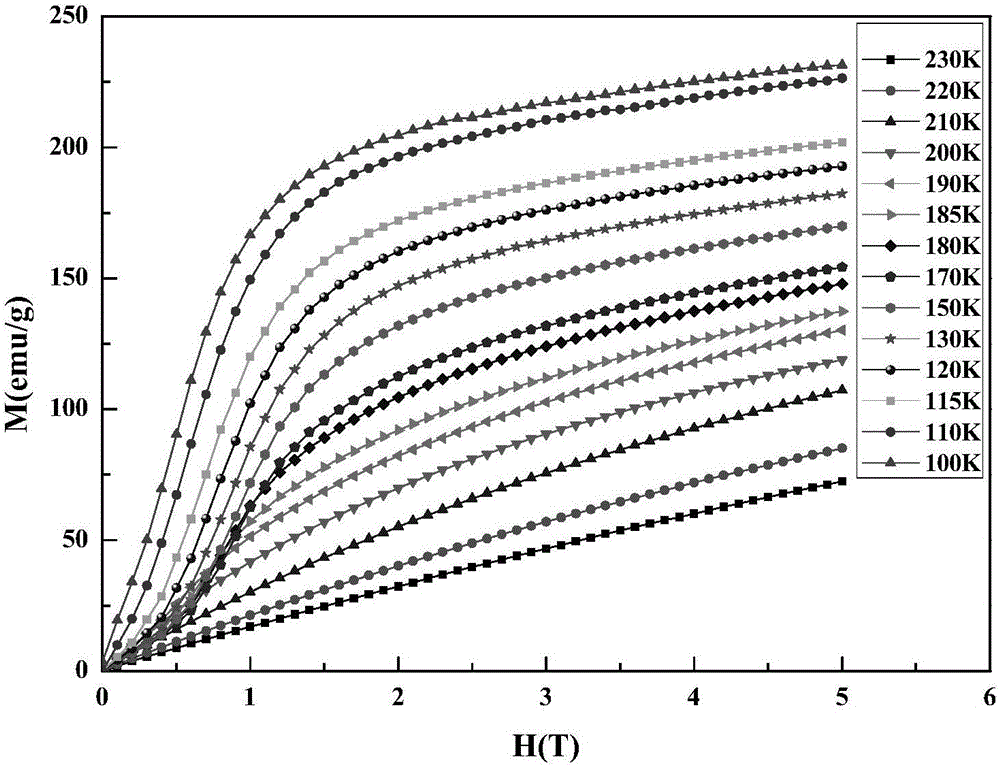

[0037] After each smelting alloy is melted, the arc is kept for 30s-60s, and the alloy block is turned over after cooling. Each alloy needs to be smelted 4 times to ensure that the composition of the master alloy is uniform. The nominal composition (atomic percentage) of embodiment alloy is Gd respectively 20 Dy 20 Er 20 Ho 20 Tb 20 , Gd 25 Er 25 Ho 25 Tb 25 and Er 33.33 Ho 33.33 Tb 33.34 . Take an appropriate amount of master alloy material and place it in a copper mold with cooling water, and re-melt it in an electric arc furnace under an argon atmosphere. After re-melting, the alloy melt is suction-cast into the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com