Comprehensive utilization method of neodymium iron boron waste acid leaching slag

A waste acid, NdFeB technology, applied in iron oxide, fibrous fillers, process efficiency improvement, etc., can solve the problems of polluting the environment, no comprehensive utilization method, occupying space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

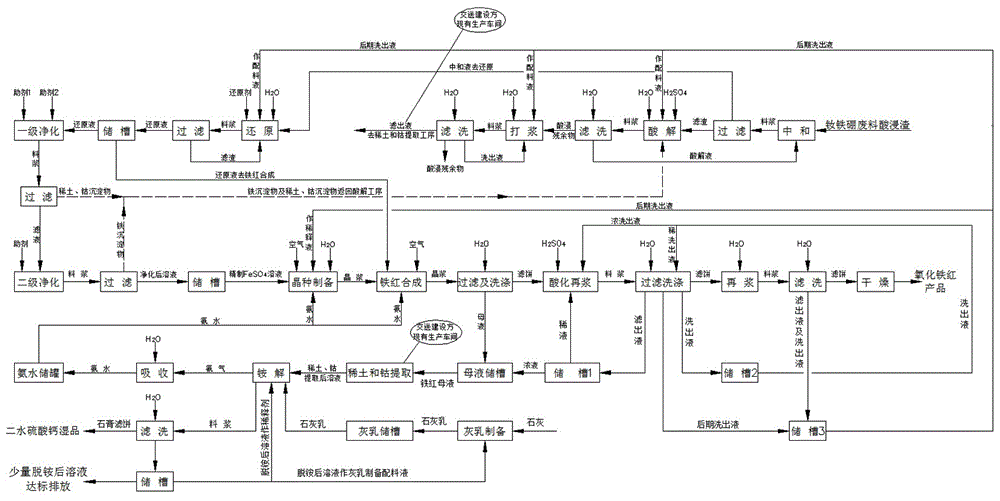

Image

Examples

Embodiment 1

[0040] Raw material composition used: Fe 2 o 3 53.54%; REO1.00%; Co0.65%.

[0041] Mix 100kg of NdFeB waste acid leaching residue with 295kg of acid leaching solution in a neutralization reactor, control the temperature at 70°C for 180 minutes, filter after the reaction, and wash with a small amount of water to obtain 69kg of neutralization residue and 355kg of neutralization solution. The main components of the neutralizing solution are: Fe 2 (SO 4 ) 3 131.3kg; REO0.4kg; Co0.62kg;

[0042] Mix and stir 69kg of neutralized residue with 105kg of iron red post-eluate in the acid leaching reactor to form a slurry, then add 106kg of concentrated sulfuric acid with a concentration of 98%, and the reaction time is 240min at 70°C. Filtrate at ℃ and wash with a small amount of water to obtain 295kg of acid leaching solution and 27kg of wet acid leaching residue.

[0043] Add 27kg of acid leaching residue to the reslurry washing tank and add the eluate 135kg, stirred into a slu...

Embodiment 2

[0052] Raw material composition used: Fe 2 o 3 67.53%; REO0.85%;

[0053] Mix 1000kg of NdFeB waste acid leaching residue with 3410kg of acid leaching solution in a neutralization reactor, control the temperature at 100°C, and take 360min. After the reaction, filter at 90°C and wash with a small amount of water to obtain neutralization residue 600kg, neutralizing solution 3850kg. The main components of the neutralizing solution are: Fe 2 (SO 4 ) 3 1665kg; REO3.80kg;

[0054] Mix 600kg of neutralization residue with 1500kg of iron red post-eluate in the acid leaching reactor to form a slurry, then add 1560kg of concentrated sulfuric acid with a concentration of 98%, and the reaction time is 180min at 90°C. Filtrate at ℃ and wash with a small amount of water to obtain 3410kg of acid leaching solution and 250kg of wet acid leaching residue.

[0055] Add 250kg of acid leaching residue to the reslurry washing tank and add the eluate 300kg, stirred into a slurry and then fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com