Producing and refining method for high-purity cycloastragenol

A technology for cycloastragaloside and astragaloside IV is applied in the field of high-purity cycloastragaloside production and refining, which can solve the problems of many reaction steps, complicated processes, injury to operators and the like, and achieves the advantages of fewer reaction steps, high operation efficiency and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

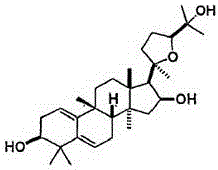

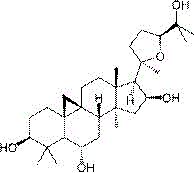

Image

Examples

Embodiment 1

[0024] A. Two-phase enzymatic hydrolysis

[0025] 1000ml0.02MKH 2 PO 4 - Add 20g of 90% astragaloside IV and 4.0g of β-glucosidase to NaOHPH5.0 buffer solution, stir and suspend, add 1000ml of ethyl acetate, stir slowly, and react at 37°C for 48h;

[0026] B. Extraction

[0027] After the enzymatic hydrolysis reaction is over, let it stand for 1 hour, take the upper layer of ethyl acetate solution; add 500ml of ethyl acetate to the water phase, stir well and then let it stand for 1 hour, after the water phase and the organic phase are completely separated, take the upper layer of ethyl acetate solution Solution; two ethyl acetate solutions were combined, filtered, and the ethyl acetate was recovered to obtain 10.68 g of the crude product of cycloastragenol. The purity of the cycloastragenol crude product detected by HPLC was 83.20%, and the conversion rate was 78.98%;

[0028] C. Recrystallization

[0029] Take 5 g of the crude product of cycloastragenol and add it to 250 ...

Embodiment 2

[0032] A. Two-phase enzymatic hydrolysis

[0033] 800ml0.04MNaH 2 PO 4 - Add 10g of 80% astragaloside IV and 2.0g of helicase to NaOHPH5.5 buffer solution, stir and suspend, add 800ml of dichloromethane, stir slowly, and react at 40°C for 58h;

[0034] B. Extraction

[0035] After the enzymatic hydrolysis reaction, let stand for 1.5h, remove the dichloromethane solution in the lower layer; add 500ml of dichloromethane to the water phase, stir well and then let it stand for 1h, after the water phase and the organic phase are completely separated, remove the dichloromethane solution in the lower layer. Methane solution; two dichloromethane solutions were combined, filtered, and dichloromethane was recovered to obtain 4.25 g of crude product of cycloastragenol, the purity of cycloastragenol crude product detected by HPLC was 78.32%, and the conversion rate was 66.57%;

[0036] C. Recrystallization

[0037] Add 2 g of the crude cycloastragenol to 100 ml of ethyl acetate, add 0...

Embodiment 3

[0039] A. Two-phase enzymatic hydrolysis

[0040] 1500ml0.04MNaH 2 PO 4 -In NaOHPH6.0 buffer solution, add 20g85% astragaloside IV, 3.0g naringinase, 1.0g helicase, stir and suspend, add 1000ml chloroform, stir slowly, and react at 30°C for 60h;

[0041] B. Extraction

[0042] After the enzymatic hydrolysis reaction is over, let stand for 2 hours, take the chloroform solution of the lower layer; add 1000ml of chloroform to the water phase, stir well and then let it stand for 1 hour, after the water phase and the organic phase are completely separated, take the chloroform solution of the lower layer; combine the chloroform twice solution, filtered, reclaimed chloroform to obtain crude product 11.29g of cycloastragenol, the purity of cycloastragenol crude product detected by HPLC was 79.41%, and the conversion rate was 84.38%;

[0043] C. Recrystallization

[0044] Take 5 g of the crude product of cycloastragenol and add it to a mixed solvent of 400 ml of acetone and petrole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com