Multi-layer anti-rust packaging material

A technology of packaging materials and anti-rust layers, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as affecting normal use, reducing value, and failing to guarantee the anti-corrosion of mechanical equipment, achieving extended service life, Reasonable structure and excellent water-repellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

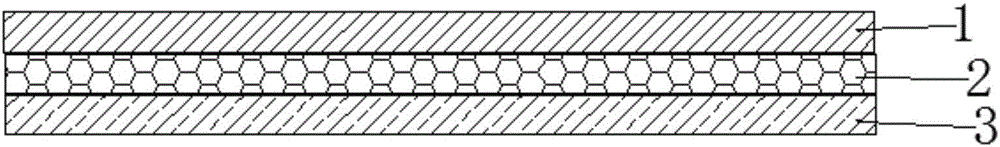

[0047] Including protective layer, load-bearing layer and anti-rust layer compounded in sequence, among which:

[0048] The protective layer specifically includes the following components in parts by mass: 100 parts of silicone resin FS-5001H, 15 parts of toluene, 0.5 parts of DF-899 accelerator, 0.5 parts of glacial acetic acid, 1 part of crosslinking agent DF-897, 15 parts of lead chrome yellow, 2 parts of anti-ultraviolet absorber UV-120, 0.5 part of antioxidant 1098;

[0049] The load-bearing layer is 300D Oxford cloth;

[0050] The antirust layer specifically includes the following components in parts by mass: 100 parts of aromatic polyether polyurethane HD-303, 20 parts of toluene, 18 parts of butanone, 3 parts of multifunctional aliphatic isocyanate bridging agent DD-100 , 1 part of fluorocarbon resin waterproofing agent FT-15, 30 parts of antirust agent VPCI-307;

Embodiment 2

[0052] Including protective layer, load-bearing layer and anti-rust layer compounded in sequence, among which:

[0053] The protective layer specifically includes the following components in parts by mass: 100 parts of silicone resin FS-5001H, 18 parts of toluene, 0.8 parts of FS-856 accelerator, 0.8 parts of glacial acetic acid, 1.5 parts of crosslinking agent FS-857, 18 parts of lead chrome yellow, 2 parts of anti-ultraviolet absorber UV-328, 0.5 part of antioxidant 1098;

[0054] The bearing layer is 150D filament fabric;

[0055]The antirust layer specifically includes the following components in parts by mass: 90 parts of aromatic polyether polyurethane T-0212, 22 parts of toluene, 22 parts of methyl ethyl ketone, 3 parts of multifunctional aliphatic isocyanate bridging agent DD-100 , 3 parts of fluorocarbon resin waterproofing agent FT-15, 40 parts of antirust agent VPCI-609;

Embodiment 3

[0057] Including protective layer, load-bearing layer and anti-rust layer compounded in sequence, among which:

[0058] The protective layer specifically includes the following components in parts by mass: 110 parts of silicone resin FS-5001H, 16 parts of toluene, 1 part of DF-899 accelerator, 1 part of glacial acetic acid, 2 parts of crosslinking agent DF-897, 15 parts of lead chrome yellow, 2 parts of anti-ultraviolet absorber UV-120, 0.5 part of antioxidant 1098;

[0059] The load-bearing layer is a 500D filament fabric;

[0060] The antirust layer specifically includes the following components in parts by mass: 100 parts of aromatic polyether polyurethane HD-303, 15 parts of toluene, 19 parts of butanone, 3 parts of multifunctional aliphatic isocyanate bridging agent DD-100 , 1 part of fluorocarbon resin waterproofing agent FT-15, 30 parts of antirust agent VPCI-609;

[0061] Table 1 Basic properties of fabrics

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com