A kind of preparation method of organic acid salt intercalation modified montmorillonite

A technology of organic acid salts and organic sulfonates, which is applied in chemical instruments and methods, dyeing low-molecular organic compound treatment, inorganic pigment treatment, etc., to achieve improved compatibility, improved thermal stability and flame retardant performance, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) First prepare a modified montmorillonite, the specific operation steps are as follows:

[0025] Add 10g of montmorillonite powder to 300ml of deionized water, stir well to obtain a uniform dispersion, adjust the pH of the solution to 2.00 with dilute hydrochloric acid, and press ZnCl 2 The ratio with montmorillonite 1.2CEC, adding ZnCl 2 Inorganic salt, fully reacted and condensed and refluxed for 2 hours to obtain a uniform suspension;

[0026] The solvent in the product obtained above was removed by centrifugation to obtain a precipitate, which was washed several times with deionized water and ethanol. The obtained product is dried, ground and sieved to obtain a primary modified montmorillonite.

[0027] 2) Using primary modified montmorillonite powder as raw material to prepare secondary modified montmorillonite, the specific operation steps are as follows:

[0028] Add 2g of primary modified montmorillonite powder to 150ml of deionized water, stir well to obta...

Embodiment 2

[0032] Add 15g of montmorillonite powder to 300ml of deionized water, stir well to obtain a uniform dispersion, adjust the pH of the solution to 3.00 with dilute hydrochloric acid, and when the temperature reaches 50°C, press MgCl2 With the ratio of montmorillonite 0.8CEC, add MgCl 2 Inorganic salt, fully reacted and refluxed for 2h to obtain a uniform suspension. The solvent in the product obtained above was removed by centrifugation to obtain a precipitate, which was washed several times with deionized water and ethanol. The obtained product is dried, ground and sieved to obtain a primary modified montmorillonite;

[0033] Add 3g of primary modified montmorillonite powder to 150ml of deionized water, stir well to obtain a dispersion with uniform concentration, after the temperature reaches 80°C, according to the ratio of sodium stearate carboxylate and montmorillonite 2.7CEC, Sodium stearate carboxylate was added, fully reacted and refluxed for 2 hours to obtain a uniform s...

Embodiment 3

[0035] Add 10g of montmorillonite powder to 300ml of deionized water, stir well to obtain a uniform dispersion, adjust the pH of the solution to 2.00 with dilute hydrochloric acid, and press CaCl after the temperature reaches 60°C 2 With the ratio of montmorillonite 1.7CEC, add CaCl 2 Inorganic salts, fully reacted and refluxed for 30 minutes to obtain a uniform suspension. The solvent in the product obtained above was removed by suction filtration to obtain a precipitate, which was washed with deionized water and ethanol several times. The obtained product is dried, ground and sieved to obtain a primary modified montmorillonite;

[0036] Add 3g of primary modified montmorillonite powder to 250ml of deionized water, stir well to obtain a dispersion with uniform concentration, after the temperature reaches 60°C, according to the ratio of sodium stearate carboxylate and montmorillonite 2.0CEC, Sodium stearate carboxylate was added, fully reacted and refluxed for 3 hours to obt...

PUM

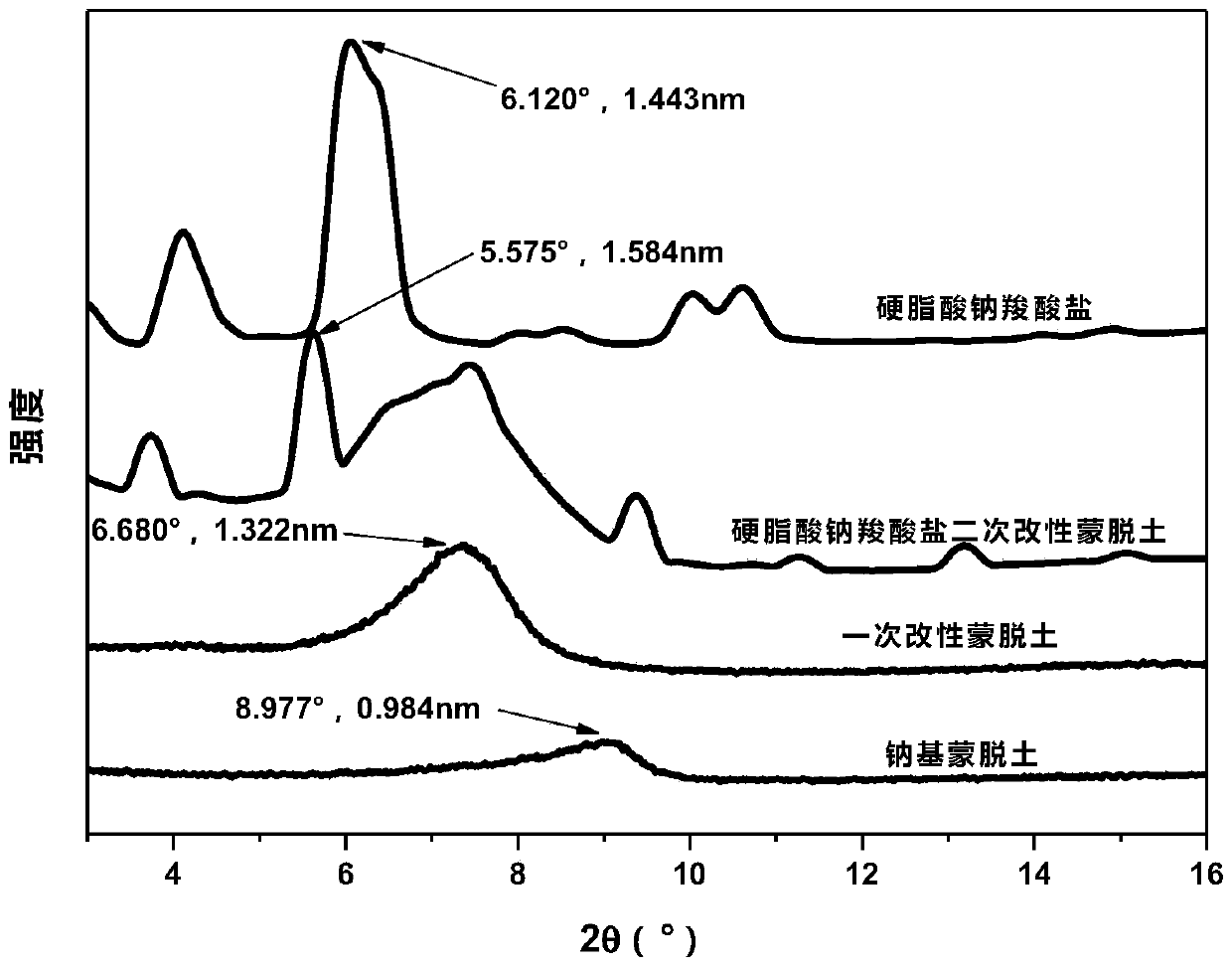

| Property | Measurement | Unit |

|---|---|---|

| 2theta | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com