Method for preparing cell grade ferrous oxalate with steel acid pickling waste liquor

A technology of iron and steel pickling waste liquid and ferrous oxalate, which is applied in the direction of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of poor crystal phase structure and crystallinity, which affects the quality of ferrous oxalate products , The process is not well controlled, etc., to achieve the effect of uniform particles, more profits, and better crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

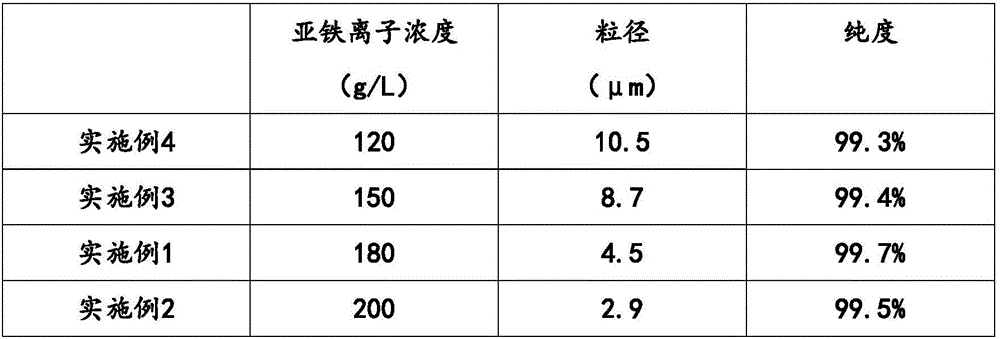

Embodiment 1

[0027] (1) Pretreatment of waste iron and steel pickling: raise the temperature of waste iron and steel pickling to 85°C, add iron filings to adjust the concentration of ferrous ions to 180g / L, and use sulfuric acid and deionized water to adjust the pH value of the solution to 2 , At this time, a black oily substance will appear on the surface of the solution. Use a straw to remove the black oily substance produced on the surface of the solution, keep it warm at 85°C for 6 hours, and filter to remove impurities after standing still;

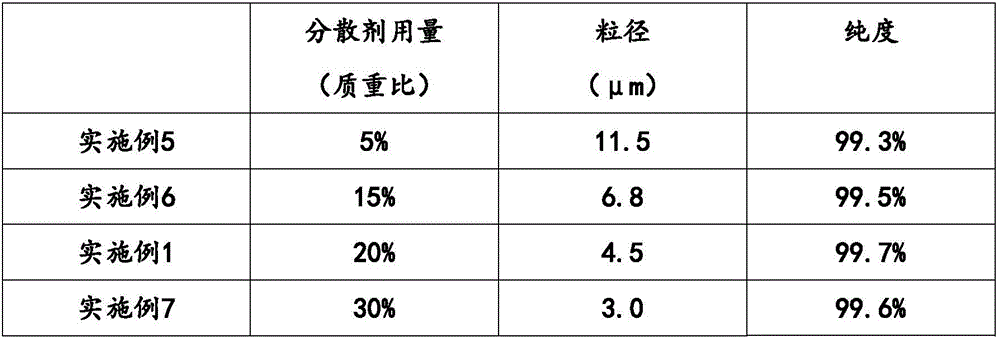

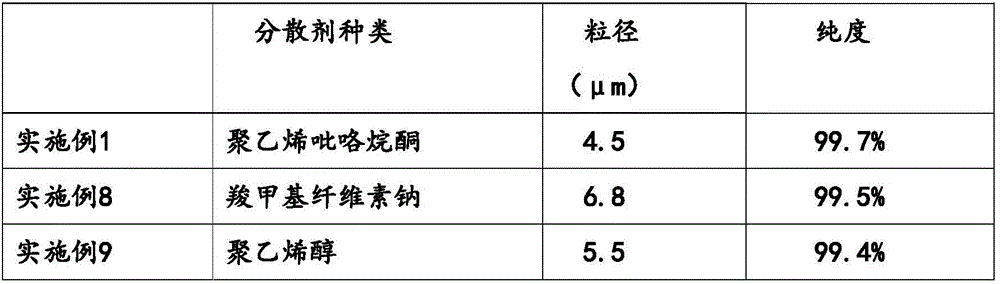

[0028] (2) Adding a dispersant: adding a mass-to-weight ratio of 20% dispersant polyvinylpyrrolidone to the solution pretreated in step (1), and mixing evenly;

[0029] (3) Generate ferrous hydroxide suspension: add ammoniacal liquor to adjust the pH value of the solution to 6 in the solution treated in step (2), and control the reaction temperature to be 25° C. to generate ferrous hydroxide suspension;

[0030] (4) generate ferrous oxalate preci...

Embodiment 2

[0033] All the preparation processes are the same as in Example 1, except that in step (1), an appropriate amount of iron filings is added and the acidity is adjusted by sulfuric acid and deionized water to adjust the ferrous ions to 200g / L.

Embodiment 3

[0035] All the preparation processes are the same as in Example 1, except that in step (1), an appropriate amount of iron filings is added and acidity is adjusted by sulfuric acid and deionized water to adjust the ferrous ions to 150g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com