Machining device for retractable door production

A technology for processing equipment and telescopic doors, which is applied in metal processing equipment, shearing machine equipment, grinding/polishing equipment, etc. It can solve the problem of unsatisfactory use effect of cutting equipment, and achieve balanced reaction force, stable power output and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

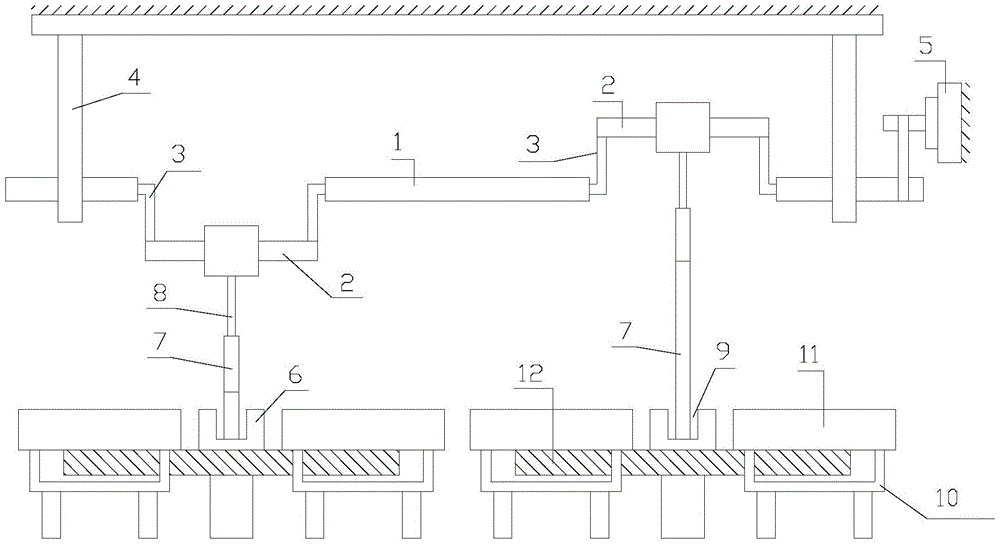

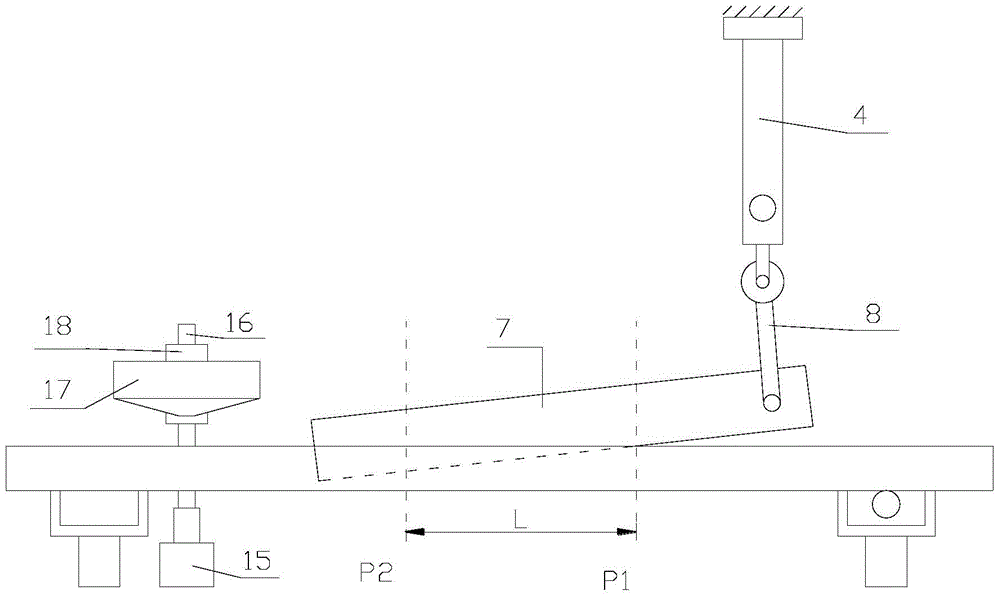

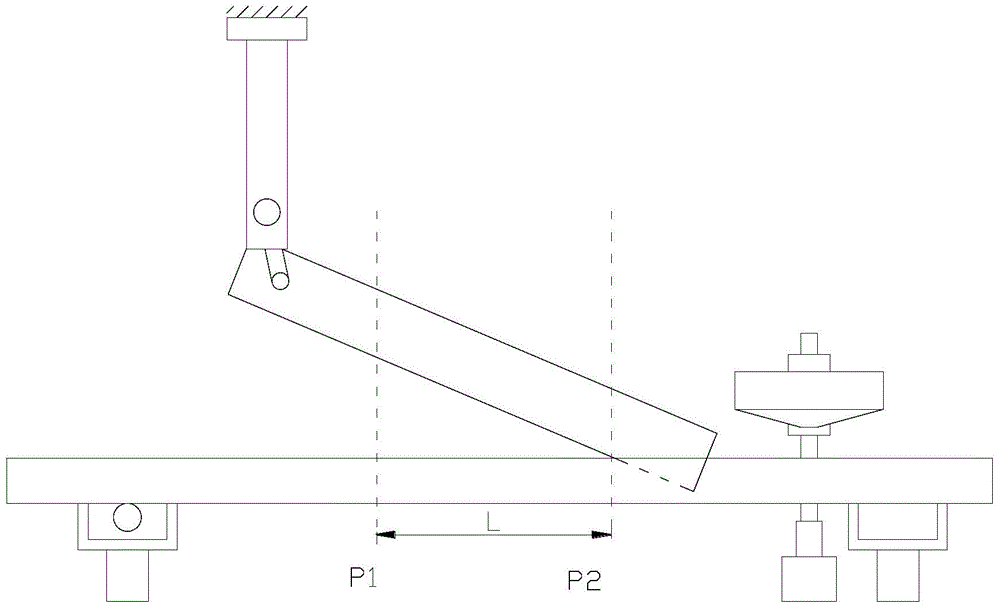

[0029] refer to figure 1 , 2 , 3, 4:

[0030] figure 1 The middle driving gear and the grinding unit are not shown.

[0031] A processing equipment for telescopic door production proposed by the present invention includes N first rotating shafts 1, (N-1) second rotating shafts 2, connectors 3, brackets 4, drive units 5, (N-1) transmission Organization, where, N>1, N is a positive integer.

[0032] N first rotating shafts 1 are arranged in sequence, N first rotating shafts 1 and (N-1) second rotating shafts 2 are distributed at intervals, and two first rotating shafts 1 distributed at both ends are rotationally connected with bracket 4 .

[0033] Both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com